Application of heavy metal detection sensing material

A technology for sensing materials and heavy metals, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of limitation, difficulty in balancing strength and toughness, etc., to improve activity, benefit uniformity of reaction, and improve mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

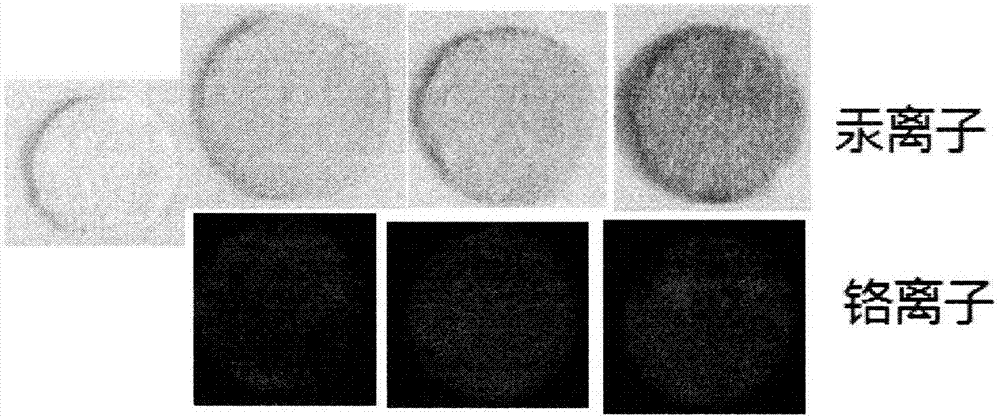

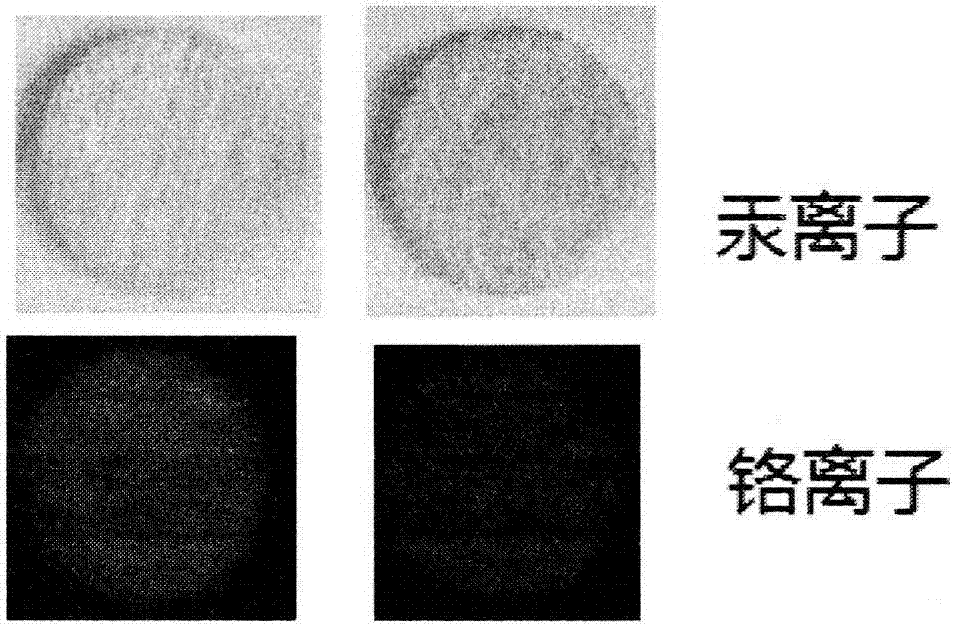

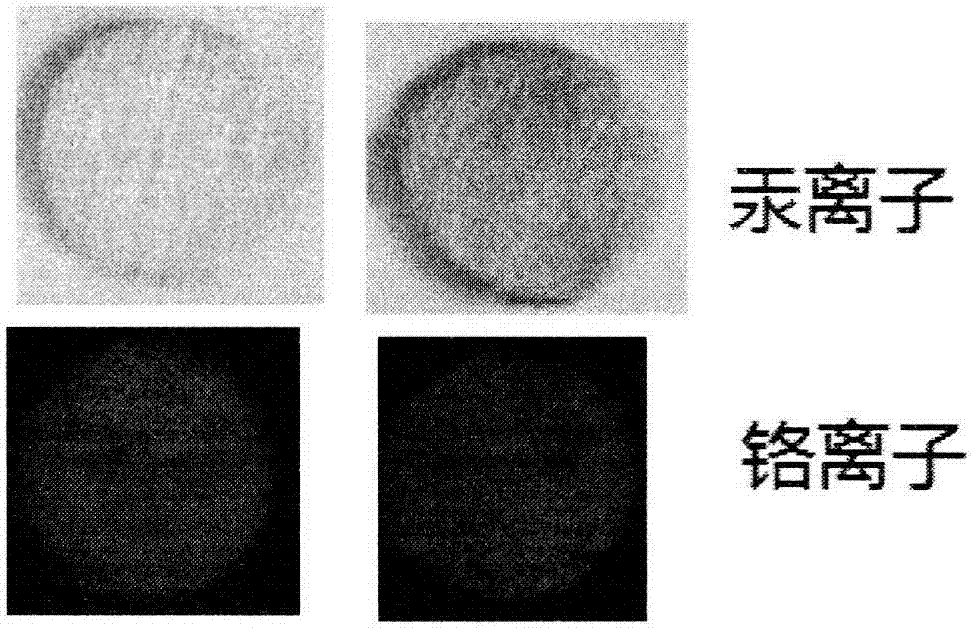

Image

Examples

Embodiment 1

[0028] Embodiment 1 A preparation method of a heavy metal detection sensing material, comprising the following steps:

[0029] (1) Add 50g of N,N-dimethylaminoethyl methacrylate, 50g of N-isopropylacrylamide, and 7g of ethyl 2-bromoisobutyrate into 200g of butane, stir for 10 minutes, and then add 3g of dimethicone Isopropylethylamine, stirred at 50°C for 15 minutes, then added 1.2g of N,N-copper di-n-butyldithiocarbamate, stirred for 30 minutes, cooled to room temperature, then added 3g of bis(2,6-difluoro -3-(1H-pyrrol-1-yl)phenyl)titanium and 50g ethanol, under stirring, light reaction for 8 hours; after the reaction, the reaction solution was added to water, and then the upper layer solution was taken to be an acrylic acid prepolymer solution ;

[0030](2) Add 25g octamethylcyclotetrasiloxane and 2.5g rhodamine compound in the acrylic acid prepolymer solution, stir at 60°C for 2 hours; then add 3g phthalic anhydride and continue stirring for 15 minutes; adjust the solid c...

Embodiment 2

[0033] Embodiment 2 A preparation method of a heavy metal detection sensing material, comprising the following steps:

[0034] (1) Add 20g of N,N-dimethylaminoethyl methacrylate, 80g of N-isopropylacrylamide, and 8g of ethyl 2-bromoisobutyrate into 200g of butane, stir for 10 minutes, and then add 4g of dimethicone Isopropylethylamine, stirred at 50°C for 15 minutes, then added 1.3g of N,N-di-n-butyldithiocarbamate copper, stirred for 30 minutes, cooled to room temperature, then added 3.5g of bis(2,6-bis Fluoro-3-(1H-pyrrol-1-yl)phenyl)titanium and 50g ethanol, under stirring, react under light for 8 hours; after the reaction, add the reaction solution into water, and then take the upper layer solution to be an acrylic acid prepolymer solution;

[0035] (2) Add 26g of octamethylcyclotetrasiloxane and 3.5g of rhodamine compound into the acrylic acid prepolymer solution, stir at 60°C for 2 hours; then add 4g of phthalic anhydride and continue stirring for 15 minutes; adjust the...

Embodiment 3

[0038] Embodiment 3 A preparation method of a heavy metal detection sensing material, comprising the following steps:

[0039] (1) Add 60g of N,N-dimethylaminoethyl methacrylate, 40g of N-isopropylacrylamide, and 7g of ethyl 2-bromoisobutyrate into 200g of butane, stir for 10 minutes, and then add 3g of dimethicone Isopropylethylamine, stirred at 50°C for 15 minutes, then added 1.2g of N,N-copper di-n-butyldithiocarbamate, stirred for 30 minutes, cooled to room temperature, then added 3g of bis(2,6-difluoro -3-(1H-pyrrol-1-yl)phenyl)titanium and 50g ethanol, under stirring, light reaction for 8 hours; after the reaction, the reaction solution was added to water, and then the upper layer solution was taken to be an acrylic acid prepolymer solution ;

[0040] (2) Add 25g octamethylcyclotetrasiloxane and 2.5g rhodamine compound into the acrylic acid prepolymer solution, stir at 60°C for 2 hours; then add 3g phthalic anhydride and continue stirring for 15 minutes; adjust the soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com