Ultra-tear-resistant mixing rubber and preparation method thereof

A rubber compounding and anti-tearing technology, which is applied in the field of pet products, can solve the problems of reducing the bite resistance of dog chews, short life of dog chews, and high hardness of molar sticks, etc., to increase brightness and smoothness, prolong Lifespan, effect of preventing cracking and aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

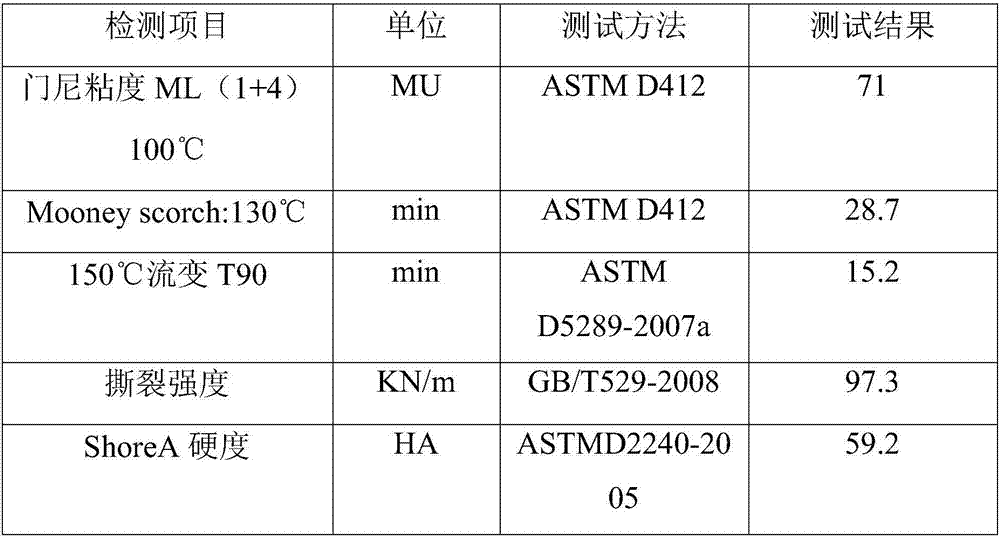

Embodiment 1

[0036] A super tear-resistant rubber compound provided in this embodiment is composed of the following raw materials in parts by mass:

[0037] Constant sticky natural rubber 60 parts

[0038] Rare earth butadiene rubber 35 parts

[0039] White carbon black 75 parts

[0040] 7.5 parts of silane coupling agent

[0041] Antioxidant 1.5 parts

[0042] 15 parts white oil

[0043] Stearic acid 1.8 parts

[0045] Guanidine accelerator 1.4 parts

[0046] 1.7 parts of sulfenamide accelerator

[0047] Sulfur 0.8 parts

[0048] Anti-scorch agent 0.3 parts

[0049] Other additives (food flavors) are added in moderation.

[0050] In this embodiment, the Mooney viscosity of constant viscosity natural rubber is 60, the rare earth butadiene rubber is neodymium BR60, the white carbon black is VN3 white carbon black, and the silane coupling agent is bis-[γ-(triethoxy Silicon) propyl] tetrasulfide (Si69), white oil is food grade white oil, guanidine acce...

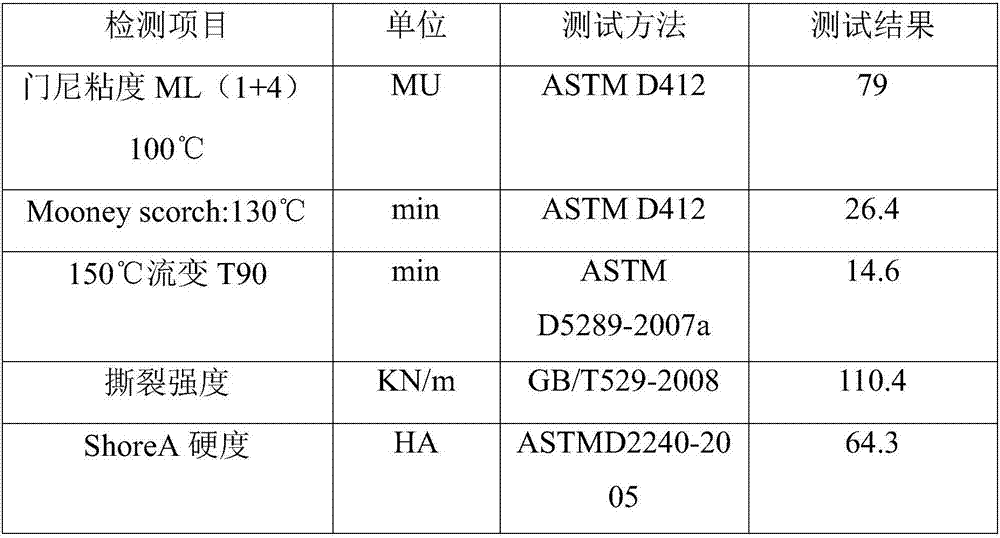

Embodiment 2

[0064] A super tear-resistant rubber compound provided in this embodiment is composed of the following raw materials in parts by mass:

[0065] Constant sticky natural rubber 65 parts

[0066] Rare earth butadiene rubber 40 parts

[0067] White carbon black 85 parts

[0068] 8.5 parts of silane coupling agent

[0069] Antioxidant 2.5 parts

[0070] 20 parts of white oil

[0071] 2.5 parts of stearic acid

[0073] Guanidine accelerator 1.8 parts

[0074] 2 parts of sulfenamide accelerator

[0075] Sulfur 1.2 parts

[0076] Anti-scorch agent 0.5 part

[0077] Other additives (food flavors) are added in moderation.

[0078] In this embodiment, the Mooney viscosity of constant viscosity natural rubber is 65, the rare earth butadiene rubber is neodymium BR60, the white carbon black is VN3 white carbon black, and the silane coupling agent is bis-[γ-(triethoxy Silicon) propyl] tetrasulfide (Si69), the antioxidant is p-cresol-dicyclopentadiene-is...

Embodiment 3

[0092] A super tear-resistant rubber compound provided in this embodiment is composed of the following raw materials in parts by mass:

[0093] Constant sticky natural rubber 60 parts

[0094] Rare earth butadiene rubber 40 parts

[0095] White carbon black 80 parts

[0096] 8 parts of silane coupling agent

[0097] Antioxidant 2 parts

[0098] White oil 25 parts

[0099] 2 parts stearic acid

[0100] Zinc oxide 4 parts

[0101] Guanidine accelerator 1.5 parts

[0102] 1.8 parts of sulfenamide accelerator

[0103] Sulfur 1.0 parts

[0104] Anti-scorch agent 0.4 parts

[0105] Other additives (food flavors) are added in moderation.

[0106] In this embodiment, the Mooney viscosity of constant viscosity natural rubber is 60, the rare earth butadiene rubber is neodymium BR60, the white carbon black is VN3 white carbon black, and the silane coupling agent is bis-[γ-(triethoxy Silicon) propyl] tetrasulfide (Si69), the antioxidant is p-cresol-dicyclopentadiene-isobutylate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com