150°C irradiation crosslinking low-smoke halogen-free flame-retardant polyolefin cable material for UL electronic wire and its preparation method

A technology of polyolefin cable materials and electronic wires, which is applied in the direction of circuits, electrical components, organic insulators, etc., can solve the problems of high cost, and achieve the effects of improved compatibility, good heat resistance, and good tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with embodiment:

[0041] Examples 1-3 and Comparative Examples 1-3: A low-smoke, halogen-free, flame-retardant polyolefin cable material for UL electronic wires irradiated at 150°C, consisting of the following components by weight shown in Table 2:

[0042] Table 2

[0043]

[0044] From embodiment and comparative example 1 comparative illustration: the weight part of modified nano-titanium dioxide, 4,4'-thiobis(6-tert-butyl-3-methylphenol) and distearyl thiodipropionate The number ratio should be (3~5):2:1.

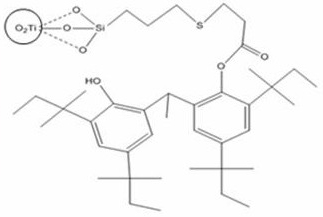

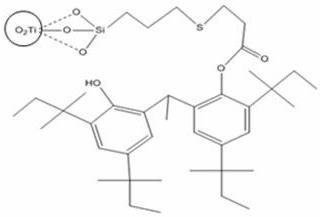

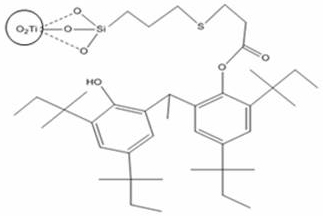

[0045] Among them, the melt index of linear low-density polyethylene is 2g / 10min; the vinyl acetate percentage content of ethylene-vinyl acetate copolymer is 33% by mass fraction; the chemical structural formula of modified nano-titanium dioxide is:

[0046]

[0047] The grafting amount of 2-[1-(2-hydroxyl-3,5-di-topentylphenyl) ethylene]-4,6-ditentylphenyl acrylate on its surface accoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com