Epoxy glue for protecting end part of stator of wind power motor and preparation method thereof

A technology of motor stator and epoxy glue, applied in the field of epoxy glue, can solve the problems of poor substrate adhesion, low tensile shear strength, etc., achieve the best low temperature resistance and heat resistance, tensile shear Good strength stability, improved crack resistance and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

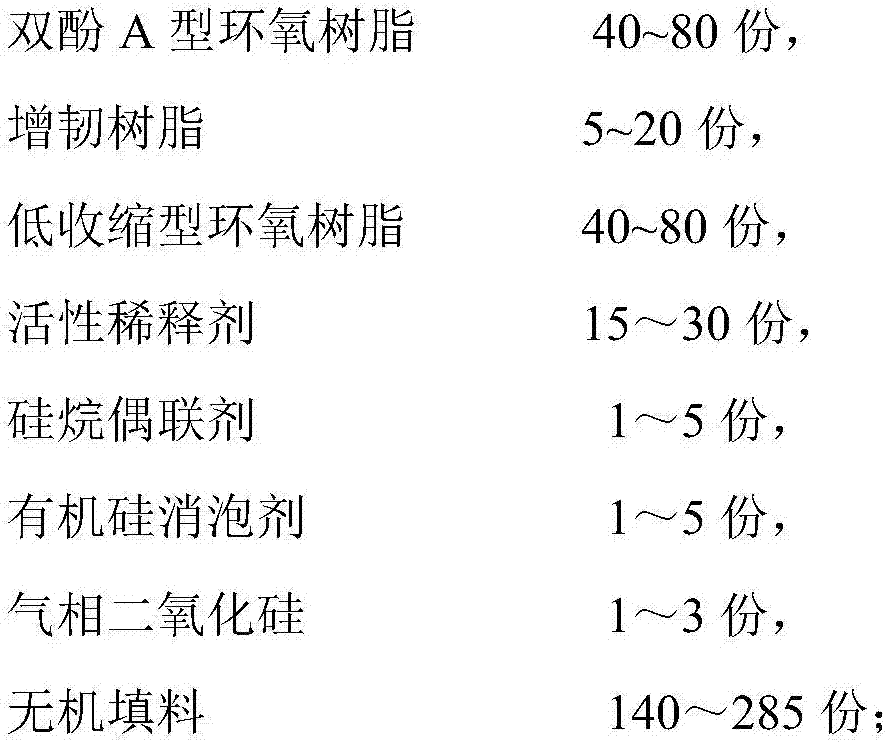

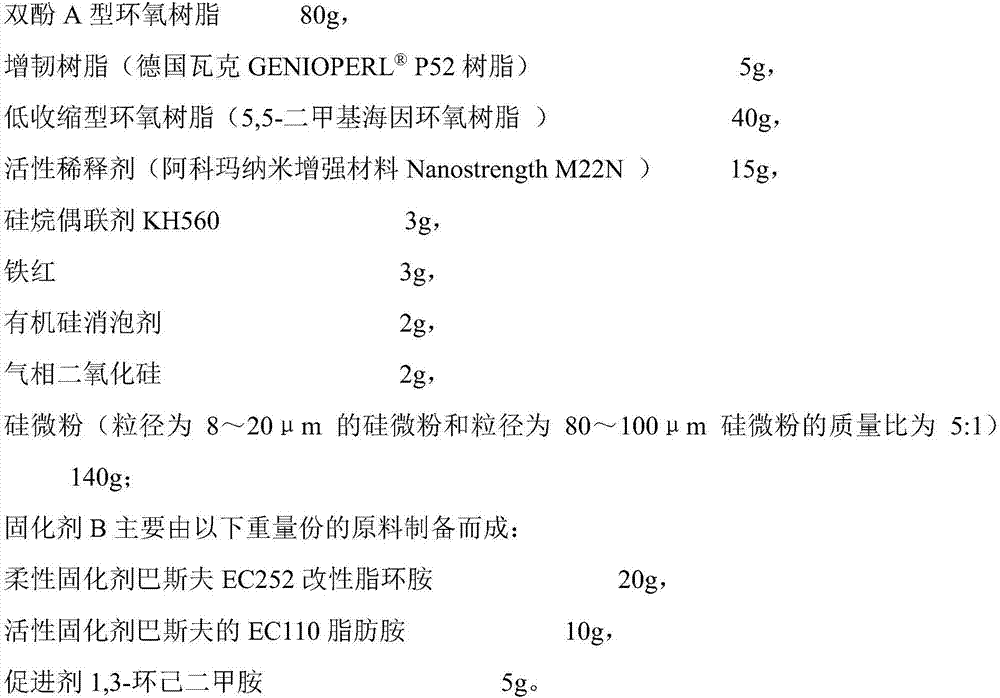

[0042] An epoxy glue for protecting the stator end of a wind power motor according to the present invention comprises a two-component main agent A and a curing agent B; wherein the main agent A is mainly prepared from the following raw materials in parts by weight:

[0043]

[0044] The preparation method of the epoxy glue for the end protection of the wind power motor stator of the present embodiment comprises the following steps:

[0045] (1) The preparation process of main agent A:

[0046] Add 80g of bisphenol A epoxy resin and 5g of toughening resin to the kettle of the high-speed disperser, then add 40g of low-shrinkage epoxy resin and 15g of reactive diluent in turn, mix well, and then add 3g of KH-560 coupling agent , 3g iron red, 2g organosilicon defoamer and stir, finally add 2g fumed silicon dioxide and 140g silicon micropowder, disperse at a high speed in a high-speed disperser for 45min, the speed of high-speed dispersion is 1000rpm, and finally obtain additive...

Embodiment 2

[0052] An epoxy glue for protecting the stator end of a wind power motor according to the present invention comprises a two-component main agent A and a curing agent B; wherein the main agent A is mainly prepared from the following raw materials in parts by weight:

[0053]

[0054]

[0055] The preparation method of the epoxy glue for the end protection of the wind power motor stator of the present embodiment comprises the following steps:

[0056] (1) The preparation process of main agent A:

[0057] Add 40g of bisphenol A epoxy resin and 10g of toughening resin to the kettle of the high-speed disperser, then add 80g of low-shrinkage epoxy resin and 30g of reactive diluent in turn, mix well, and then add 5g of KH-560 coupling agent , 1g iron red, 1g organosilicon defoamer and stir, finally add 3g fumed silicon dioxide and 285g silicon micropowder, disperse at a high speed in a high speed disperser for 45min, the speed of high speed dispersion is 1000rpm, finally get ad...

Embodiment 3

[0063] An epoxy glue for protecting the stator end of a wind power motor according to the present invention comprises a two-component main agent A and a curing agent B; wherein the main agent A is mainly prepared from the following raw materials in parts by weight:

[0064]

[0065]

[0066] The preparation method of the epoxy glue for the end protection of the wind power motor stator of the present embodiment comprises the following steps:

[0067] (1) The preparation process of main agent A:

[0068] Add 60g of bisphenol A epoxy resin and 20g of toughening resin to the kettle of the high-speed disperser, then add 80g of low-shrinkage epoxy resin and 20g of reactive diluent in turn, mix well, and then add 1g of KH-560 coupling agent , 1g iron red, 5g organosilicon defoamer and stir, finally add 3g fumed silicon dioxide and 210g silicon micropowder, disperse at a high speed in a high-speed disperser for 45min, the speed of high-speed dispersion is 1000rpm, and finally ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com