Lactic acid bacterium for high-yield gamma-aminobutyric acid and application of lactic acid bacterium

A technology of aminobutyric acid and Lactobacillus brevis, applied in the direction of microorganism-based methods, bacteria, microorganisms, etc., can solve the problems of low fermentation yield and difficult separation and purification, and achieve high fermentation yield of strains, high safety, and reduced cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

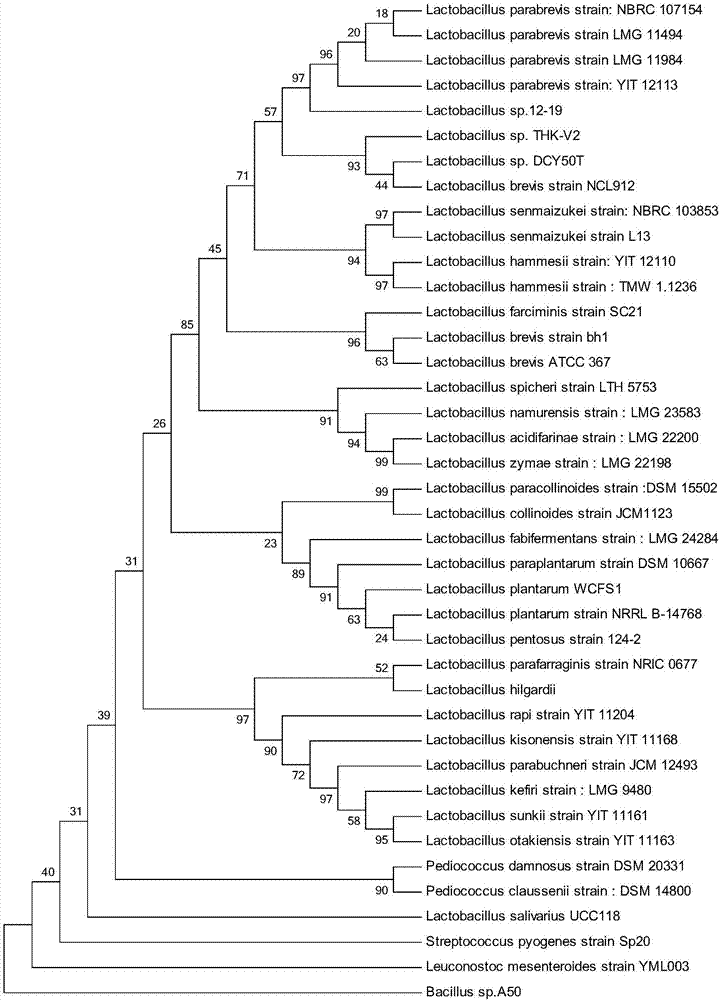

[0029] Example 1 Isolation, purification and identification of bacterial strains

[0030] Enrichment culture: Take a small amount of fresh vegetables, homemade sauerkraut, vegetable soil samples, purchased sauerkraut, fresh milk and other samples and add lactic acid bacteria medium (MRS medium, component g / L: peptone 10.0, beef extract powder 4.0, yeast extract powder 4.0, glucose 20.0, dipotassium hydrogen phosphate 2.0, triammonium citrate 2.0, sodium acetate 5.0, magnesium sulfate 0.2, manganese sulfate 0.05, Tween-801.0), 30 ℃ static culture for 2 days.

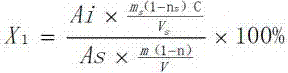

[0031] Qualitative detection: paper chromatography (or thin-layer chromatography), spotting the diluted fermentation broth on qualitative filter paper (or silica gel prefabricated plate), and developing with chromatographic fluid. The chromatographic solution uses n-butanol: glacial acetic acid: water (60:15:25), and adds 0.4% ninhydrin. After unfolding, let it dry naturally, develop color at 85 ºC for 10 minutes, dilu...

Embodiment 2

[0033] Example 2 Preparation of high-purity γ-aminobutyric acid

[0034] (1) Seed solution preparation: Inoculate the HX12-19 strain into the culture medium, shake the flask for fermentation, and obtain the seed solution;

[0035] (2) Fermentation: Culture for 9 hours, OD 600 The seed solution >0.8 was added to the liquid medium (10L) in a 10L fermenter, and the medium components were: peptone 10.0 g / L, yeast powder 10.0 g / L, glucose 10.0 g / L, Tween 80 1.0 mL / L , sodium acetate 5.0g / L, dipotassium hydrogen phosphate 2.0g / L, magnesium sulfate 0.5g / L, manganese sulfate 0.2g / L, monosodium glutamate (sodium glutamate ≥ 95%) 10.0g / L. Ventilation and agitation culture When cultured for 18 hours, OD600=2.9, the fermentation was completed, and the fermentation liquid was obtained;

[0036] (3) Transformation: collect the bacteria by centrifugation, add purified water to about 5L, add sodium glutamate, control the temperature at 30±2°C, start stirring, and carry out the reaction. Du...

Embodiment 3

[0040] Example 3 Preparation of high-purity γ-aminobutyric acid

[0041] (1) Seed liquid preparation: Inoculate the HX12-19 strain into the culture medium, shake the flask for fermentation, and obtain the seed liquid;

[0042] (2) Fermentation: Culture for 8 hours, OD 600The seed solution >0.8 was added to the liquid medium (10L) in a 10L fermenter, and the medium components were: peptone 10.0 g / L, yeast powder 10.0 g / L, glucose 10.0 g / L, Tween 80 1.0 mL / L , sodium acetate 5.0g / L, dipotassium hydrogen phosphate 2.0g / L, magnesium sulfate 0.5g / L, manganese sulfate 0.3g / L, monosodium glutamate (sodium glutamate ≥ 95%) 10.0g / L. Ventilation and agitation culture When cultured for 20 hours, OD600=3.1, the fermentation was completed, and the fermentation liquid was obtained;

[0043] (3) Transformation: collect the bacteria by centrifugation, add purified water to about 5L, add sodium glutamate, control the temperature at 30±2°C, start stirring, and carry out the reaction. During ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com