An MOF-precious metal composite SERS substrate and a preparing method thereof

A precious metal, MOF technology, applied in the field of MOF-precious metal composite SERS substrate and its preparation, can solve the problems of poor detection signal, large specific surface area, large porosity, weak binding ability, etc., and achieve high repetition rate, high porosity, and specific surface area. falling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

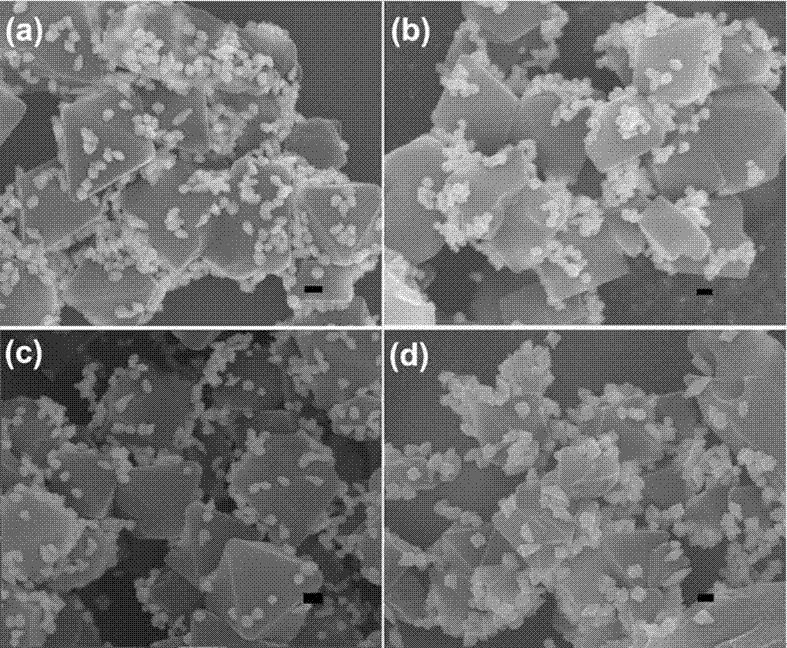

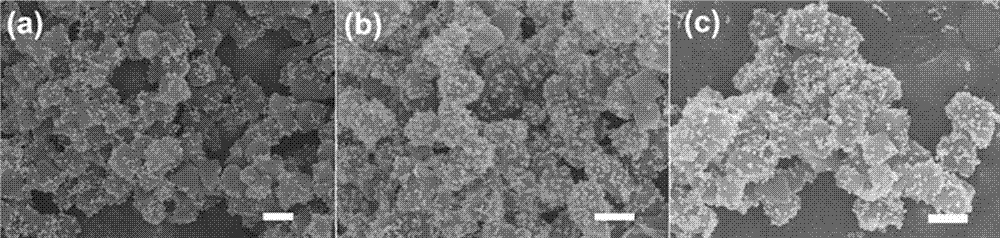

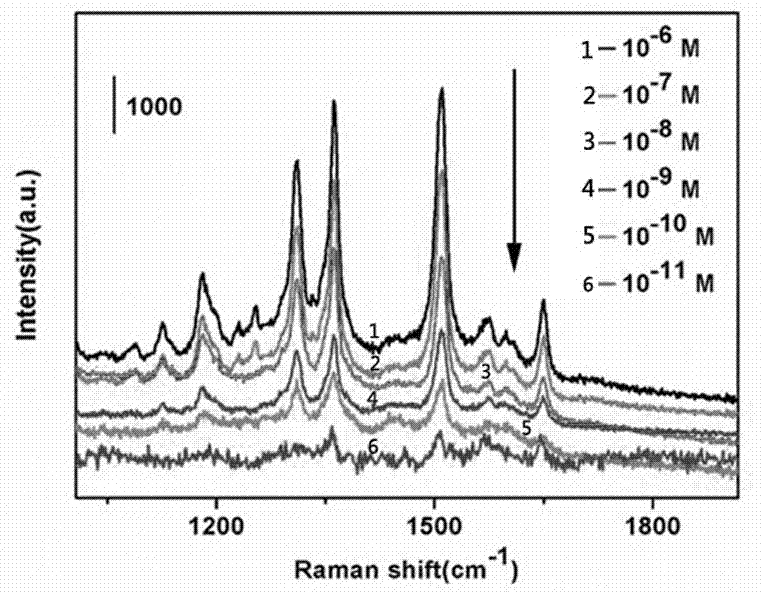

[0029] The preparation method of described MOF-AuNPs composite SERS substrate, comprises the steps:

[0030] ① Preparation of MIL-101: Add 5mmol of chromium nitrate nonahydrate, hydrofluoric acid, terephthalic acid and 24mL of deionized water into the reaction kettle, keep the temperature at 220°C for 12h, then gradually cool down to 150°C within 1h, Slowly drop to room temperature within 12h. The product was centrifuged to obtain MIL-101(Cr) powder. Disperse 1 mg of MIL-101(Cr) powder in 10 mL of methanol to obtain a MIL-101(Cr) methanol dispersion with a concentration of 0.1 mg / mL.

[0031] (1) Preparation of AuNPs: Rapidly add sodium borohydride (0.01M, 0.6mL) solution at 2-4°C to tetrachloroauric acid (0.01M, 0.25mL) and CTAB (0.1M, 7.5mL) by seed growth method ) in the mixed solution, vigorously stirred for 1 min, and stood at room temperature for 1 h to obtain gold seeds.

[0032] Add CTAB (0.1M, 6.4mL), tetrachloroauric acid (0.01M, 6.8mL), and ascorbic acid (0.1M, 3...

Embodiment 1

[0040] The preparation of gold seed, its step is:

[0041] Quickly add sodium borohydride (0.01M, 0.6mL) solution at 2-4°C to a mixed solution of tetrachloroauric acid (0.01M, 0.25mL) and CTAB (0.1M, 7.5mL), stir vigorously for 1min, and After standing for 1 h, gold seeds (8.35 mL) were obtained.

Embodiment 2

[0043] The preparation of gold seed growth solution, its step is:

[0044] Add CTAB (0.1M, 6.4mL), tetrachloroauric acid (0.01M, 6.8mL), and ascorbic acid (0.1M, 3.8mL) to 32mL ultrapure water in turn to prepare a gold seed growth solution (49 mL).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com