Organic polymer enhanced graphene intercalation material for lithium-sulfur batteries

A technology of organic polymers and intercalation materials, which is applied in the field of chemical energy storage batteries, can solve the problems of polysulfide interception, difficulty in transfer, and limited mechanical strength of the film, so as to increase surface roughness, improve electrical conduction efficiency, and improve The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

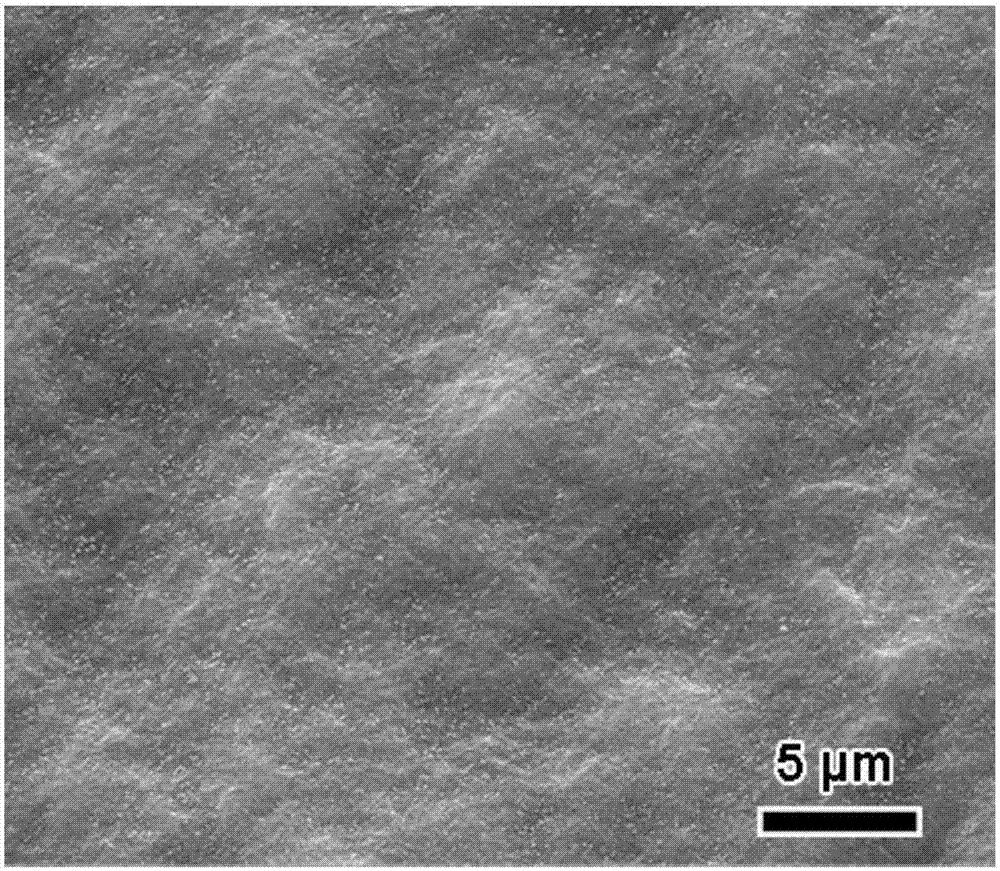

[0049] Step 1. The dispersion containing 60mg graphene oxide (GO), that is, the concentration of graphene oxide is 3.3mg·mL -1 Pour 100mL of deionized water into 100mL of deionized water, stir for 1h and continue to sonicate for 0.5h to fully disperse GO and obtain a GO dispersion; add 80mL of Tris buffer and 15mg of dopamine hydrochloride solid powder to the GO dispersion successively, and continuously stir After 24 hours, the color of the solution turned black, and a PDA-crosslinked graphene solution was obtained; filter with a vacuum pump, add 15 mL of Tris buffer and 20 mL of deionized water, and then filter with a vacuum pump to obtain a filter membrane loaded with PG membrane.

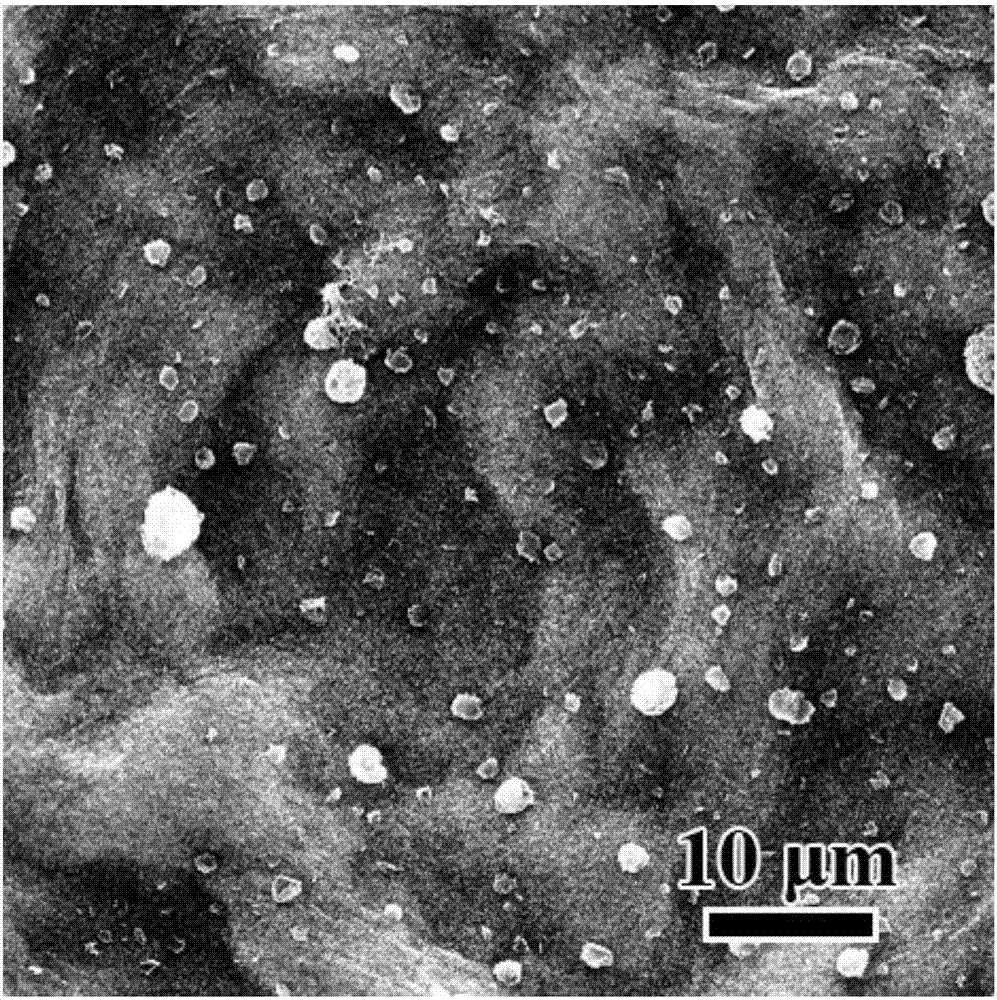

[0050] Step 2. Add 1mg·mL -1 Add 15mL of PEI aqueous solution to the filter membrane loaded with PG membrane, and filter it with a vacuum pump until the surface of the membrane is basically dry, then add 15mL Tris buffer solution and 50mL deionized water, continue to pass through the filter membr...

Embodiment 2

[0055] Step 1. With embodiment 1 step 1.

[0056] Step 2. Mix 1.5mg·mL -1 Add 15mL of PEI aqueous solution to the filter membrane loaded with PG membrane, and filter it with a vacuum pump until the surface of the membrane is basically dry, then add 15mL Tris buffer solution and 50mL deionized water, continue to pass through the filter membrane sequentially, and use a vacuum pump to filter it. After the filtration was completed, the filter membrane was taken out, compacted with a glass plate, and then moved into an oven at 50° C. for 4 hours to dry to obtain a filter membrane loaded with PPG membrane.

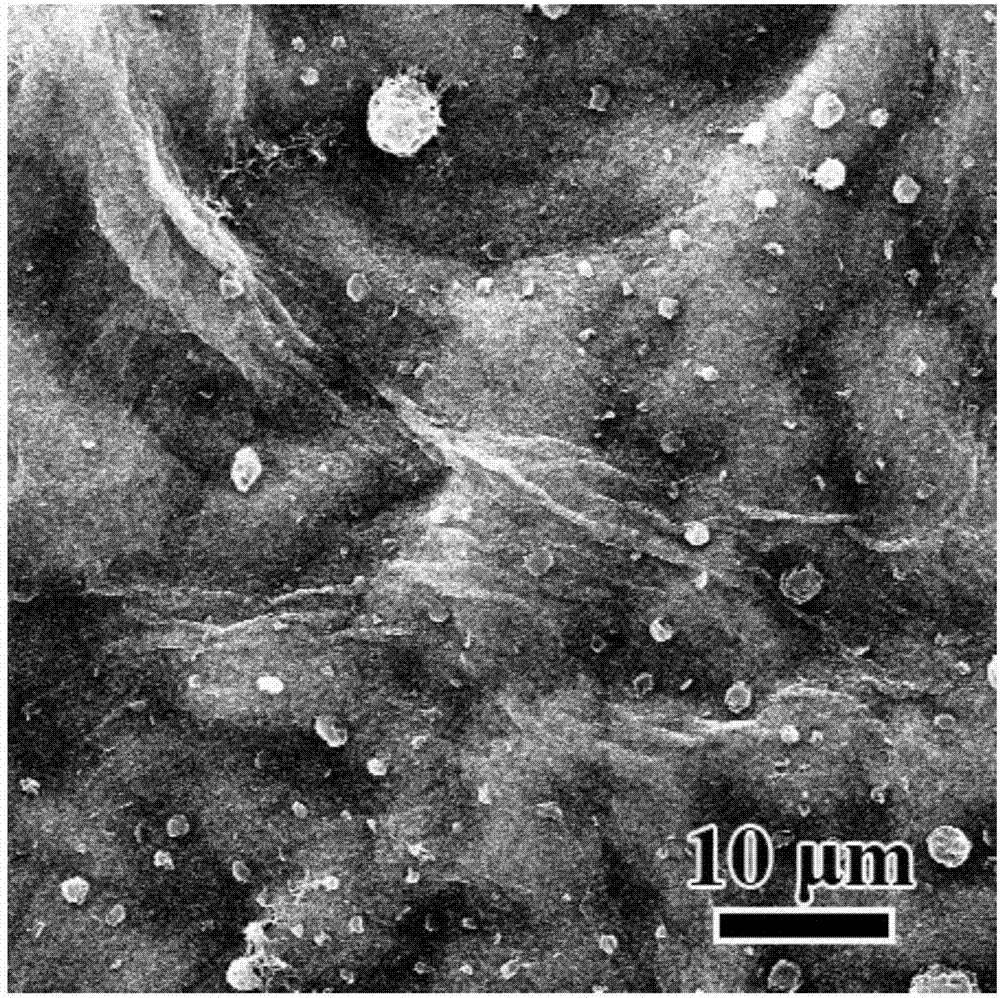

[0057] Step 3. Fix the filter membrane loaded with PPG membrane with a glass plate, immerse it in 60℃, the concentration is 4mol L -1 hydriodic acid solution in 15mL for 20min, after the filter membrane is dissolved, the impurity-containing PPG membrane is taken out, soaked in 20mL acetone and 60mL deionized water for 8h to remove impurities, and after drying, the PPG film is o...

Embodiment 3

[0062] Step 1. With embodiment 1 step 1.

[0063] Step 2. Add 2mg mL -1 Add 15mL of PEI aqueous solution to the filter membrane loaded with PG membrane, and filter it with a vacuum pump until the surface of the membrane is basically dry, then add 20mL Tris buffer solution and 50mL deionized water, continue to pass through the filter membrane in turn, and use a vacuum pump to filter it. After the filtration was completed, the filter membrane was taken out, compacted with a glass plate, and then moved into an oven at 60° C. for 2 hours to dry to obtain a filter membrane loaded with PPG membrane.

[0064] Step 3. Fix the filter membrane loaded with PPG membrane with a glass plate, immerse it in 90℃, the concentration is 2mol L -1 hydriodic acid solution in 20mL for 40min, after the filter membrane is dissolved, the impurity-containing PPG membrane is taken out, soaked in 20mL acetone and 50mL deionized water for 8h to remove impurities, and after drying, a PPG film is obtained, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com