Preparation method and application of biological-based oxygen, sulfur and nitrogen codoped porous carbon

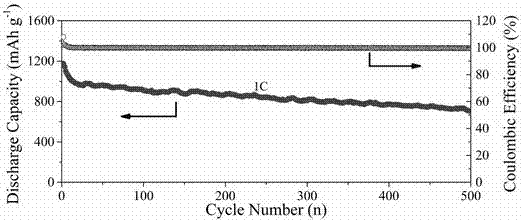

A bio-based, co-doping technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, other chemical processes, etc., can solve the problem that aquatic animal skin or bone is not effectively used, pollutes the environment, and wastes resources. and other problems, to achieve the effect of improving the cycle performance of the battery, abundant sources and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

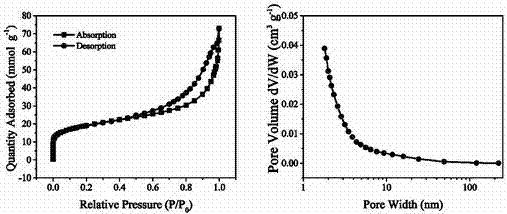

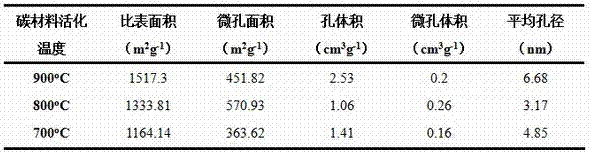

Embodiment 1

[0026] Clean the fish bones and put them in 60 o C oven, placed for 24 hours to dry. The dried fish bones are crushed into aquatic animal skin or bone powder with a grinder, placed in a tube furnace and heated to 330 °C under an inert gas atmosphere. o C, and keep the temperature for 3 hours for low-temperature pre-carbonization; mix the pre-carbonized fishbone powder and activator evenly according to the ratio of 5:1, and then place the mixed powder in a tube furnace to heat up to 700 o C, high-temperature carbonization at constant temperature for 1 hour to obtain bio-based carbonized powder. The bio-based carbonized powder was placed in 1mol / L hydrochloric acid solution for 3 times of pickling to remove the inorganic template and active agent in the bio-based carbonized powder, and then filtered and washed with deionized water repeatedly. Put the finished product in 80 o C dried in an oven for 24 hours to obtain oxygen, sulfur and nitrogen co-doped bio-based porous carbon...

Embodiment 2

[0028] Clean the fish bones and put them in 60 o C oven, placed for 24 hours to dry. Grind the dried aquatic animal skin or bone into aquatic animal skin or bone powder with a pulverizer, place it in a tube furnace and heat it to 330 °C under an inert gas atmosphere. o C, and keep the temperature for 3 hours for low-temperature pre-carbonization; the pre-carbonized fishbone powder and activator are evenly mixed according to the ratio of 5:1, and then the mixed powder is placed in a tube furnace and heated to 800 o C, high-temperature carbonization at constant temperature for 1 hour to obtain bio-based carbonized powder. The bio-based carbonized powder was placed in 1mol / L hydrochloric acid solution for 3 times of pickling to remove the inorganic template and active agent in the bio-based carbonized powder, and then filtered and washed with deionized water repeatedly. Put the finished product in 80 o C dried in an oven for 24 hours to obtain oxygen, sulfur and nitrogen co-do...

Embodiment 3

[0030] Clean the fish bones and put them in 60 o C oven, placed for 24 hours to dry. The dried fish bones are crushed into aquatic animal skin or bone powder with a grinder, placed in a tube furnace and heated to 330 °C under an inert gas atmosphere. o C, and keep the temperature for 3 hours for low-temperature pre-carbonization; uniformly mix the pre-carbonized fishbone powder and activator according to the ratio of 5:1, and then place the mixed powder in a tube furnace to heat up to 900 oC, high-temperature carbonization at constant temperature for 1 hour to obtain bio-based carbonized powder. The bio-based carbonized powder was placed in 1mol / L hydrochloric acid solution for 3 times of pickling to remove the inorganic template and active agent in the bio-based carbonized powder, and then filtered and washed with deionized water repeatedly. Put the finished product in 80 o C dried in an oven for 24 hours to obtain oxygen, sulfur and nitrogen co-doped bio-based porous carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com