Supported palladium catalyst used for low-temperature catalytic removal of VOCs

A technology of supported palladium and low-temperature catalysis, which is applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, catalyst activation/preparation, etc. It can solve the problems of damage to aromatic hydrocarbons, reduce pore blockage, and improve high-temperature catalytic oxidation activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

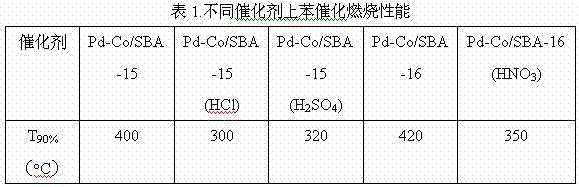

Image

Examples

preparation example Construction

[0021] Preparation of SBA-15

[0022] Vector SBA-15 was prepared according to the method described in the literature (Chem. Mater. 2000, 12:275-279).

[0023] Preparation of SBA-16

[0024] Vector SBA-16 was prepared according to the method described in the literature (Appl. Catal. A: Gen. 2013, 467:1-6).

Embodiment 1

[0026] Preparation of Pd-Co / SBA-15

[0027] (1) Weigh 0.12g of cobalt nitrate hexahydrate and dissolve it in 5ml of deionized water, stir well and record it as solution A;

[0028] (2) Weigh 0.0027g of sodium tetrachloropalladate and dissolve it in 15ml of absolute ethanol, stir well and record it as solution B;

[0029] (3) Mix A and B solutions evenly, and disperse them ultrasonically for 30 minutes;

[0030] (4) Weigh 0.9g of SBA-15 and add it to the above mixed solution, and continue ultrasonic dispersion for 30 minutes;

[0031] (5) Let the above suspension stand at room temperature for 12 hours;

[0032] (6) Put the above suspension at 40 o Rotary evaporation under C conditions until anhydrous, placed at 60 o Drying under C conditions for 24h to obtain a precursor;

[0033] (7) The obtained precursor is subjected to 450 o C is calcined to obtain Pd-Co / SBA-15 catalyst, denoted as Pd-Co / SBA-15.

Embodiment 2

[0035] Preparation of Pd-Co / SBA-16

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com