Simple synthetic method for Ag2S-MoS2 sheet self-assembling composite spherical power

A synthesis method and spherical powder technology, which is applied in the field of photocatalytic material preparation, can solve the problem of few spherical powders assembled in sheet form, and achieve the effects of easy control of product composition, less environmental pollution, and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Weigh 1.8538g of ammonium molybdate tetrahydrate, 0.4567g of thiourea, 1.1260g of glycine, 0.0255g of silver nitrate and 0.0263g of ammonium metavanadate into a beaker, and add 15mL of deionized water to dissolve. Then placed on a magnetic stirrer and stirred for 30 min.

[0021] (2) Transfer the stirred mixture into the 25mL reaction kettle washed in advance, then rinse the beaker with 5mL deionized water and pour it into the reaction kettle; cover the reaction kettle and put it in a constant temperature blast oven, set the temperature to 180°C, react for 10 hours; after the reaction is over, take out the reaction kettle, centrifuge the powder generated after the reaction, and wash it alternately with absolute ethanol and deionized water for several times, and put the washed powder in a constant temperature drying box , set the temperature at 30°C, and dry for 5 hours to obtain a dry black powder.

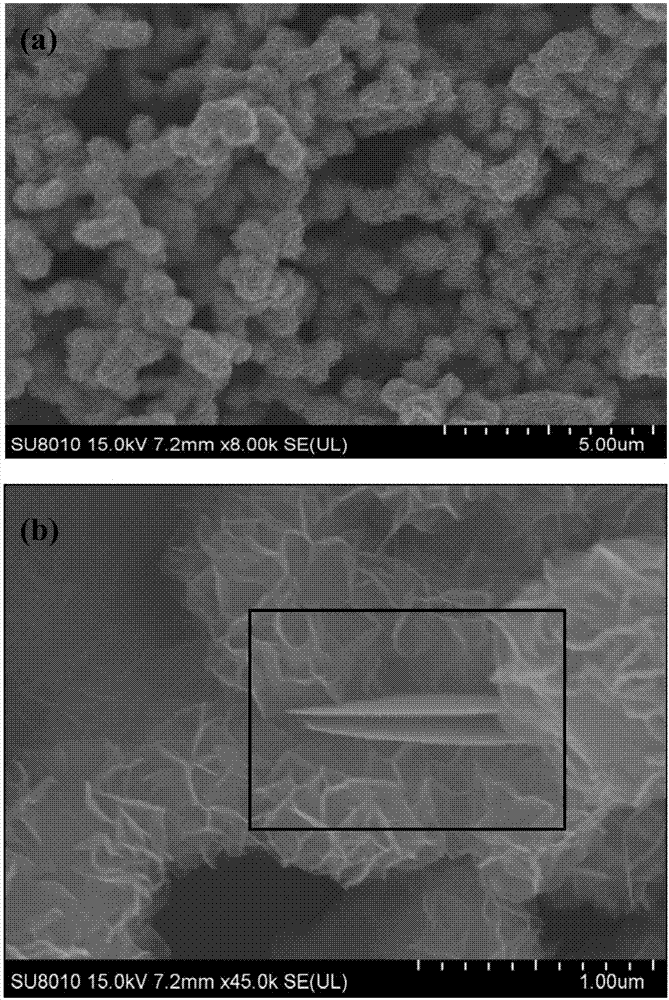

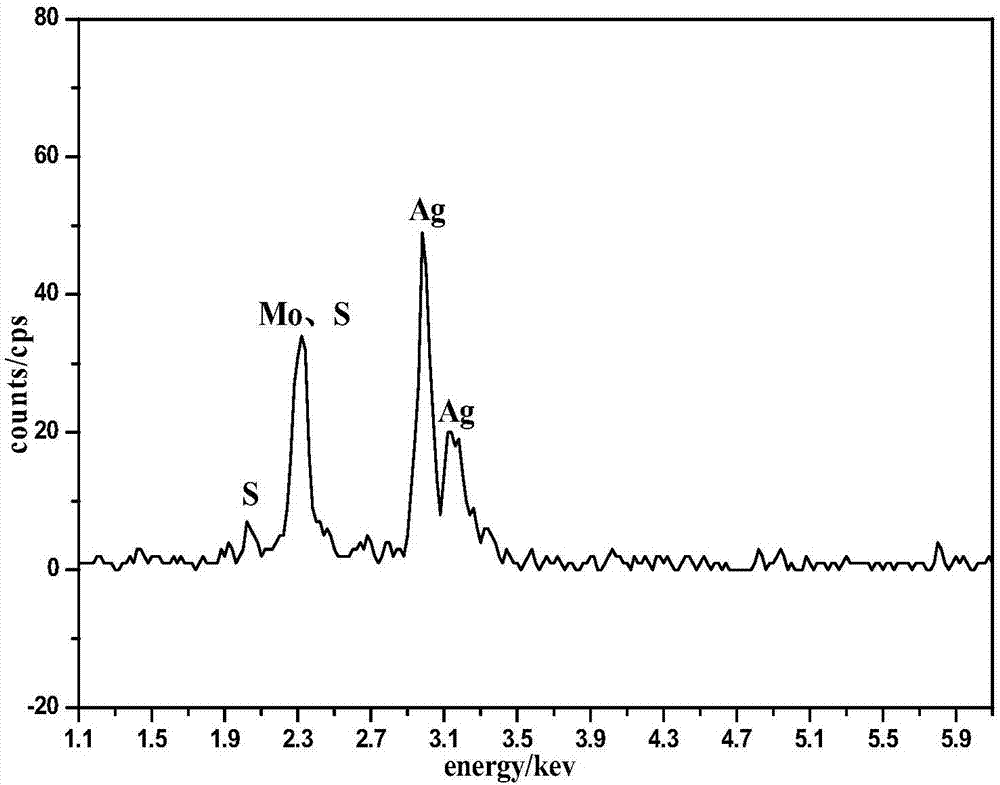

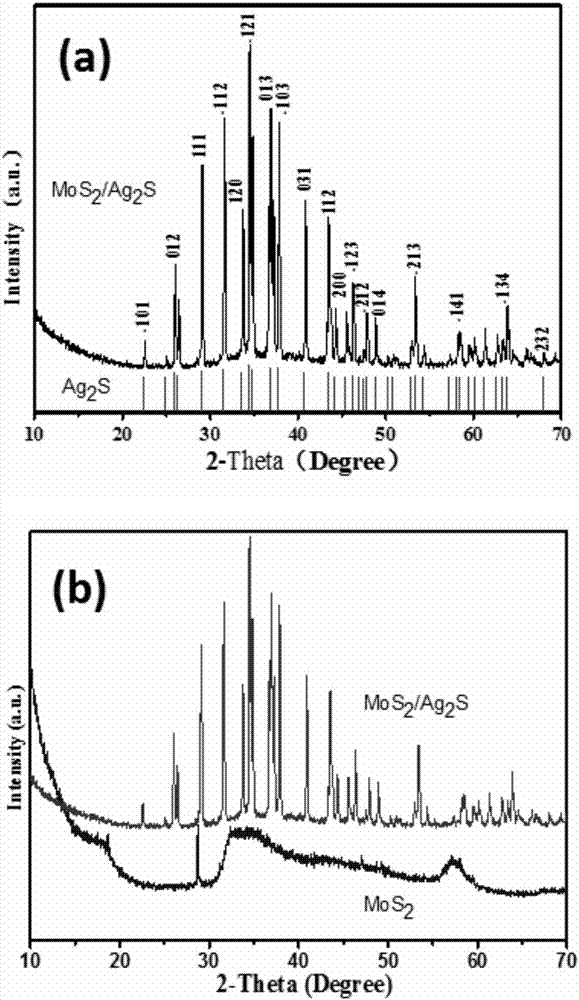

[0022] figure 1 It is the Ag prepared in Example 1 2 S-MoS 2 F...

Embodiment 2

[0026] (1) Weigh 0.9269g ammonium molybdate tetrahydrate, 0.5709g thiourea, 0.1996g L-aspartic acid, 0.1911g silver nitrate and 0.0175g ammonium metavanadate into a beaker, add 15mL deionized water to dissolve . Then placed on a magnetic stirrer and stirred for 30 min.

[0027] (2) Transfer the stirred mixture into the 25mL reaction kettle washed in advance, then rinse the beaker with 5mL deionized water and pour it into the reaction kettle; cover the reaction kettle and put it in a constant temperature blast oven, set the temperature to 160°C, react for 24 hours; after the reaction is over, take out the reaction kettle, centrifuge the powder generated after the reaction, and wash it alternately with absolute ethanol and deionized water for several times, and put the washed powder in a constant temperature drying box , set the temperature at 40°C, and dry for 10 hours to obtain a dry black powder.

[0028] Figure 5 It is the Ag prepared in Example 2 2 S-MoS 2 Field emiss...

Embodiment 3

[0030] (1) Weigh 2.7807g of ammonium molybdate tetrahydrate, 2.7403g of thiourea, 2.5336g of glycine, 0.0764g of silver nitrate and 0.0263g of ammonium metavanadate into a beaker, and add 15mL of deionized water to dissolve. Then placed on a magnetic stirrer and stirred for 30 min.

[0031] (2) Transfer the stirred mixture into the 25mL reaction kettle washed in advance, then rinse the beaker with 5mL deionized water and pour it into the reaction kettle; cover the reaction kettle and put it in a constant temperature blast oven, set the temperature to 140°C, react for 36 hours; after the reaction is over, take out the reaction kettle, centrifuge the powder generated after the reaction, and wash alternately with absolute ethanol and deionized water several times respectively, and put the washed powder in a constant temperature drying box , set the temperature at 60°C, and dry for 3 hours to obtain a dry black powder.

[0032] Image 6 It is the Ag prepared in Example 3 2 S-Mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com