Chromatographically pure ethyl ether and preparation method and production system thereof

A kind of chromatographically pure, ether technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The embodiment of the present invention provides a preparation method of chromatographically pure ether, which comprises:

[0028] S1. Using industrial grade diethyl ether as a raw material, carry out oxidation removal and neutralization reaction to obtain a reaction solution.

[0029] Colorless transparent liquid. Has a special pungent smell. with sweetness. Very volatile. Its vapor is heavier than air. Under the action of air, it can be oxidized to peroxide, aldehyde and acetic acid, and its oxidation can be promoted by exposure to light. Oxidation and impurity removal of industrial grade ether is to mix industrial grade ether with alkali and potassium permanganate. Preferably, the base includes at least one of sodium hydroxide, potassium hydroxide and calcium hydroxide. Potassium permanganate can oxidize impurities such as alcohols, aldehydes, and ketones mixed in industrial grade ether into carboxylic acids, and carboxylic acids and alkalis react to form salts...

Embodiment 1

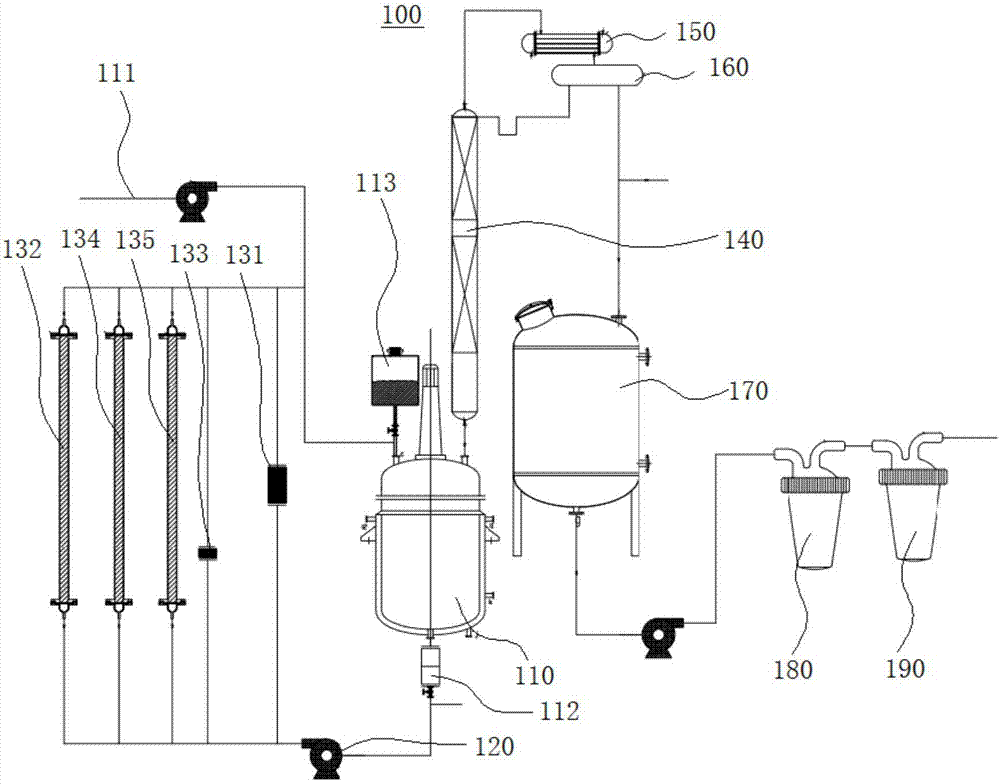

[0054] Present embodiment 1 provides a kind of production system 100 of chromatographically pure ether, with reference to figure 1 As shown, it includes: a reaction kettle 110 , a mixer 131 , a 4A molecular sieve column 132 , a calcium hydride column 133 , a basic alumina column 134 , an activated carbon adsorption column 135 , a rectification tower 140 and a circulation pump 120 .

[0055] Among them, the mixer 131 , 4A molecular sieve column 132 , calcium hydride column 133 , basic alumina column 134 , and activated carbon adsorption column 135 are arranged in parallel, and form circulation pipelines with circulation pump 120 and reaction kettle 110 respectively. Further, the input end of the circulation pump 120 is communicated with the liquid phase outlet at the bottom of the reactor 110, and the output end of the circulation pump 120 is respectively communicated with the mixer 131, 4A molecular sieve column 132, calcium hydride column 133, basic alumina column 134, The fe...

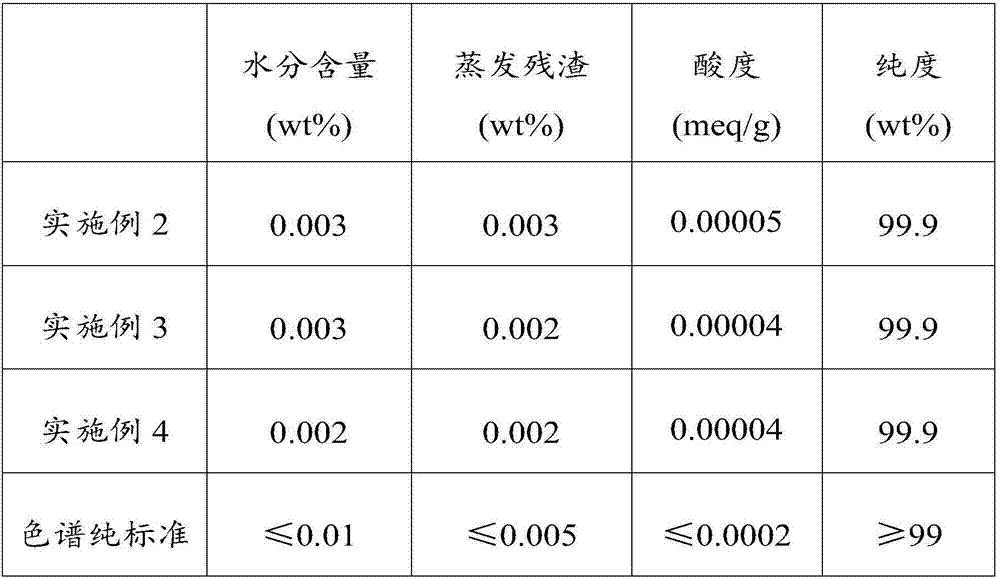

Embodiment 2

[0061] The present embodiment provides a kind of chromatographically pure diethyl ether, and its preparation method is as follows:

[0062] S1. Introduce 50L of industrial-grade ether (Jinzhou Petrochemical, purity ≥ 98wt%) raw material in the reactor 110, add 5mol% sodium hydroxide and 5mol% potassium permanganate, open the valve of the mixer 131 and the circulation pump 120 , establish the circulation between the reaction kettle 110, the circulation pump 120 and the mixer 131 until the color of the solution in the reaction kettle 110 no longer changes.

[0063] S2. Open the acid dripping tank 113, let the concentrated sulfuric acid therein drop slowly into the reaction kettle 110, and maintain the circulation for 0.5h.

[0064] S3. Add 50L of water into the reaction kettle 110, maintain the circulation for 0.5h, close the valve of the mixer 131 and the circulation pump 120, and let stand for 3h to make the solution in the reaction kettle 110 layered; remove the lower water l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com