A kind of alkyd resin and preparation method thereof

A technology of alkyd resin and acid value, which is applied in the field of resin, can solve the problems of sudden changes in atmospheric pressure, limit the application of stearic acid and palmitic acid, shorten the use time of alkyd resin, etc., and achieve yellowing resistance, weather resistance, and proportioning reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

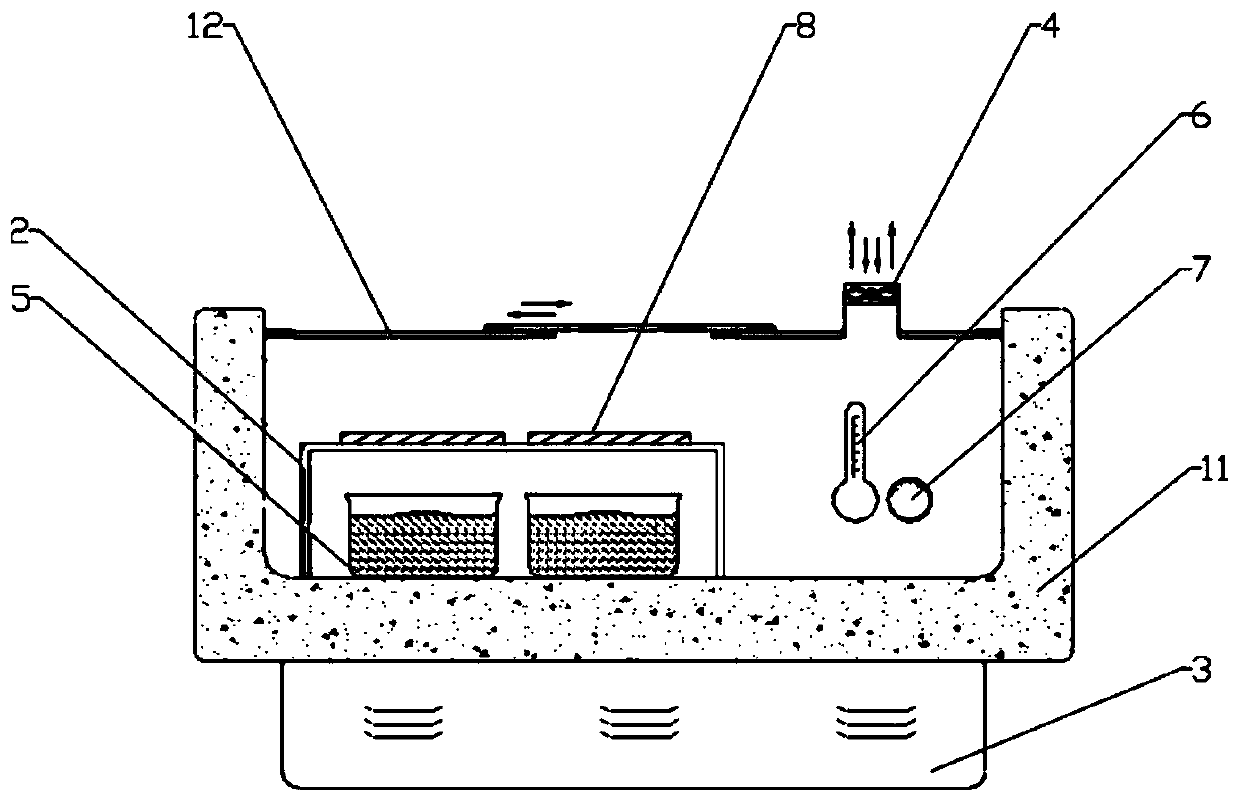

Method used

Image

Examples

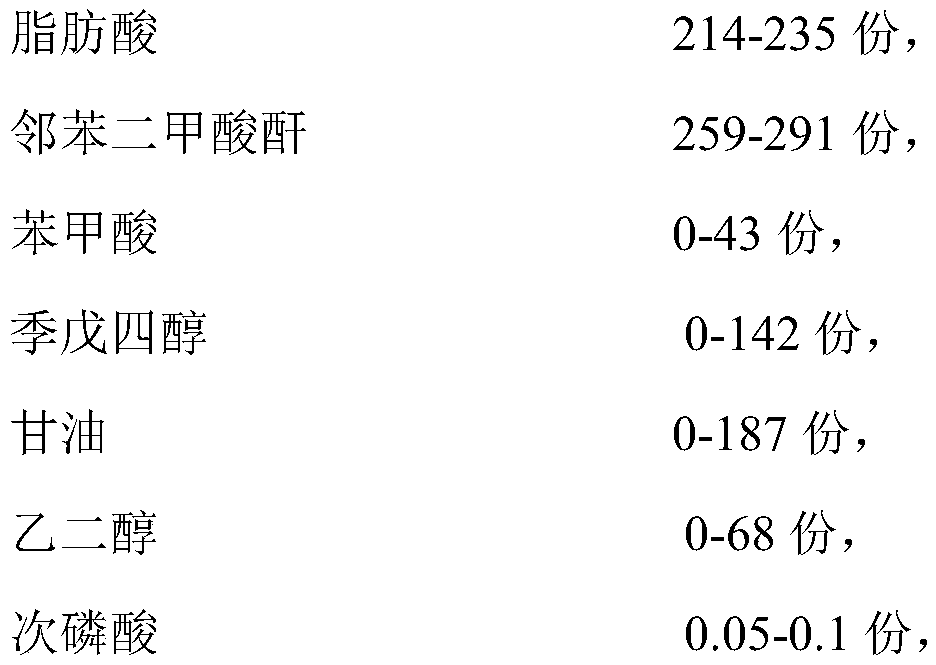

Embodiment 1

[0032] An alkyd resin for baking varnish, comprising the following components by weight: 216.3 parts of stearic acid, 269 parts of phthalic anhydride, 43 parts of benzoic acid, 187 parts of glycerin, 0.1 part of hypophosphorous acid, 0.12 part of phosphorous acid Triphenyl ester, 283.9 parts of xylene. The preparation method of alkyd resin for baking varnish comprises the following steps:

[0033] (1) Put stearic acid, benzoic acid, glycerin, hypophosphorous acid, triphenyl phosphite into the reaction vessel, vacuumize to -0.99MPa and keep vacuuming for 40 minutes;

[0034] (2) adopt 99.99% high-purity nitrogen to fill the reaction vessel to normal pressure, then open the air;

[0035] (3) Add 10-25% xylene, heat up to 120°C and start stirring;

[0036] (4) Evenly heat up to 160°C within 2-3 hours and keep it warm for 1 hour, then heat up to 210°C within 2-3 hours, keep warm until the acid value of the material is ≤1mg KOH / g;

[0037] (5) be cooled to 120 ℃, drop into the x...

Embodiment 2

[0041] An alkyd resin for baking varnish, comprising the following components by weight: 227.9 parts of stearic acid, 262.7 parts of phthalic anhydride, 42.2 parts of benzoic acid, 183 parts of glycerin, 0.1 part of hypophosphorous acid, 0.12 part of phosphorous acid Triphenyl ester, 284 parts xylene.

[0042] The preparation method of the alkyd resin for baking varnish is the same as in Example 1.

Embodiment 3

[0044] An alkyd resin for baking varnish, comprising the following components by weight: 234.1 parts of palmitic acid, 259.4 parts of phthalic anhydride, 41.7 parts of benzoic acid, 180.6 parts of glycerin, 0.1 part of hypophosphorous acid, 0.12 part of phosphorous acid Triphenyl ester, 284 parts xylene.

[0045] The preparation method of the alkyd resin for baking varnish is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com