Preparation method of flame-retardant material for wires and cables

A flame-retardant material, wire and cable technology, applied in the field of flame-retardant materials, can solve the problem that flame-retardant materials cannot take into account flame-retardant performance, mechanical performance and environmental protection, etc., to ensure mechanical performance, improve flame retardancy, and good environmental protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Embodiments of the present invention provide a method for preparing a wire and cable flame retardant material, comprising:

[0030] 1) Preparation of modified dopa polymer solution:

[0031] Using levodopa modified by benzyl chloroformate as a monomer, the modified dopa polymer is prepared through polymerization;

[0032] Dissolving the modified dopa polymer in acetone to prepare a modified dopa polymer solution;

[0033] 2) Preparation of sodium-based montmorillonite dispersion:

[0034] placing the sodium-based montmorillonite in an ethanol solution to prepare a sodium-based montmorillonite dispersion, and using an alkaline solution to adjust the pH value of the sodium-based montmorillonite dispersion to 9.5-10;

[0035] Using an ultrasonic cell pulverizer to treat the sodium-based montmorillonite dispersion for 7 to 9 minutes to obtain a uniformly dispersed sodium-based montmorillonite dispersion;

[0036] 3) Preparation of polyimide fiber substrate:

[0037] Soa...

Embodiment 1

[0043] A method for preparing a wire and cable flame retardant material, comprising:

[0044] 1) Preparation of modified dopa polymer solution:

[0045] With levodopa modified by benzyl chloroformate as a monomer, a modified dopa polymer is obtained through a polymerization reaction, and the molecular weight of the modified dopa polymer obtained is at least 6000 g / mol;

[0046] Dissolving the modified dopa polymer in acetone to prepare a modified dopa polymer solution, the concentration of the prepared modified dopa polymer solution is respectively 0.02wt%;

[0047] 2) Preparation of sodium-based montmorillonite dispersion:

[0048] The sodium-based montmorillonite is placed in an ethanol solution with a concentration of 50% V / V to make a sodium-based montmorillonite dispersion, and the concentration of the prepared sodium-based montmorillonite dispersion is 0.22wt%. The NaOH solution of 1 adjusts the pH value of the sodium-based montmorillonite dispersion to 9.5;

[0049] ...

Embodiment 2

[0057] A method for preparing a wire and cable flame retardant material, comprising:

[0058] 1) Preparation of modified dopa polymer solution:

[0059] With levodopa modified by benzyl chloroformate as a monomer, a modified dopa polymer is obtained through polymerization, and the molecular weight of the modified dopa polymer obtained is as large as 6300g / mol;

[0060] Dissolving the modified dopa polymer in acetone to prepare a modified dopa polymer solution, the concentration of the prepared modified dopa polymer solution is respectively 0.06wt%;

[0061] 2) Preparation of sodium-based montmorillonite dispersion:

[0062] The sodium-based montmorillonite is placed in an ethanol solution with a concentration of 53% V / V to make a sodium-based montmorillonite dispersion, and the concentration of the prepared sodium-based montmorillonite dispersion is 0.24wt%. adjusting the pH value of the sodium-based montmorillonite dispersion to 9.7 with a 1.2M NaOH solution;

[0063] Using ...

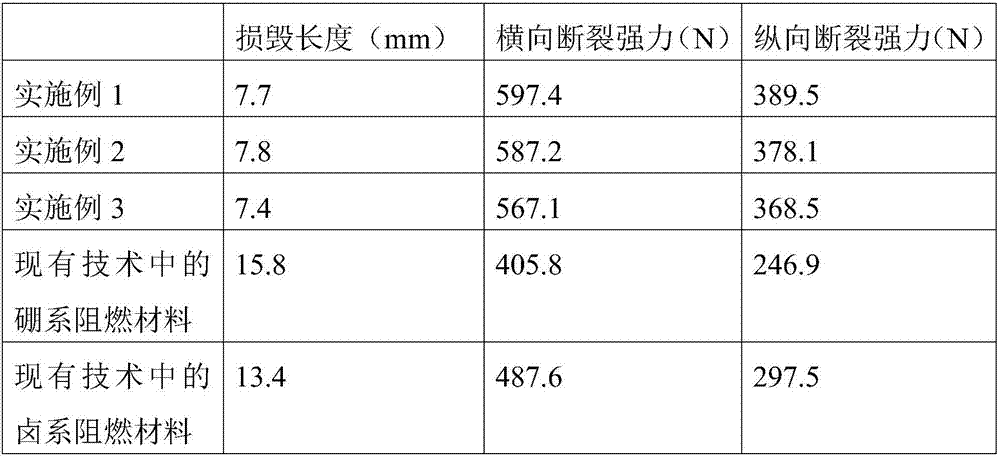

PUM

| Property | Measurement | Unit |

|---|---|---|

| Damage length | aaaaa | aaaaa |

| Transverse breaking strength | aaaaa | aaaaa |

| Longitudinal breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com