Solid lipid peach kernel polypeptide ferrous chelate nanoparticles and preparation method thereof

A technology of polypeptide ferrous and solid lipids, which is applied in food science, the function of food ingredients, and the forming of food, can solve the problems of discarding and waste of resources, achieve less waste liquid discharge, lower production costs, and improve biological utilization degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

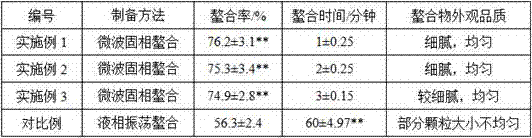

Examples

preparation Embodiment 1~3

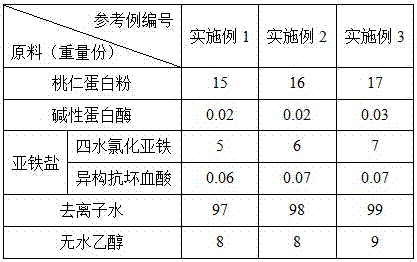

[0045] The amount of each raw material is shown in Table 1:

[0046] Table 1 The amount of raw materials used in the preparation of solid lipid peach kernel polypeptide ferrous chelate nanoparticles in Examples 1-3 Table 1

[0047]

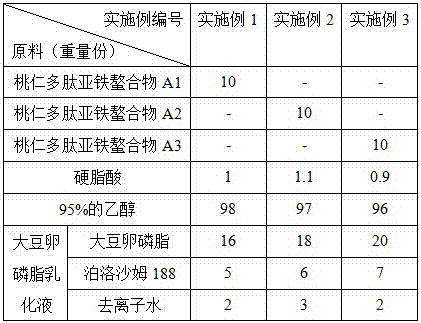

[0048] Table 2 The amount of raw materials used in the preparation of solid lipid peach kernel polypeptide ferrous chelate nanoparticles in Examples 1-3 Table 2

[0049]

[0050] Note: "-" in the table means not added.

preparation Embodiment 1

[0052] (1) Enzymatic hydrolysis of peach kernel protein: According to the weight parts of the raw materials described in Example 1 in Table 1, add ionized water to the protein powder to prepare a protein dispersion with a mass concentration of 3%, add alkaline protease to adjust the pH of the solution 9, the enzymolysis temperature is 50°C, and the enzymolysis time is 4 hours. After enzymolysis, place in a boiling water bath for 20 minutes to inactivate the enzyme, and centrifuge at a speed of 8000r / min for 12 minutes to obtain a supernatant;

[0053] (2) Membrane separation: filter the supernatant obtained in step (1) with an ultrafiltration device with a pore size of 10,000D, take the filtrate, and then filter it with a nanofiltration device with a pore size of 500D, take the filter residue, and obtain peach kernel polypeptide powder after freeze-drying;

[0054] (3) Microwave solid-phase chelation: After mixing 5 parts of the peach kernel polypeptide powder obtained in step ...

preparation Embodiment 2

[0063] (1) Enzymatic hydrolysis of peach kernel protein: according to the weight parts of the raw materials described in Example 2 of Table 1, add ionized water to the protein powder to prepare a protein dispersion with a mass concentration of 3.5%, add alkaline protease to adjust the pH of the solution 9.5, the enzymolysis temperature is 52°C, and the enzymolysis time is 4.5h. After enzymolysis, place in a boiling water bath for 18 minutes to inactivate the enzyme, and centrifuge at a speed of 7000r / min for 15 minutes to obtain a supernatant;

[0064] (2) Membrane separation: filter the supernatant obtained in step (1) with an ultrafiltration device with a pore size of 11000D, take the filtrate, and then filter it with a nanofiltration device with a pore size of 400D, take the filter residue, and obtain peach kernel polypeptide powder after freeze-drying;

[0065] (3) Microwave solid-phase chelation: After mixing 12 parts of the peach kernel polypeptide powder obtained in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com