Anti-reduction X9R ceramic capacitor dielectric material and preparation method thereof

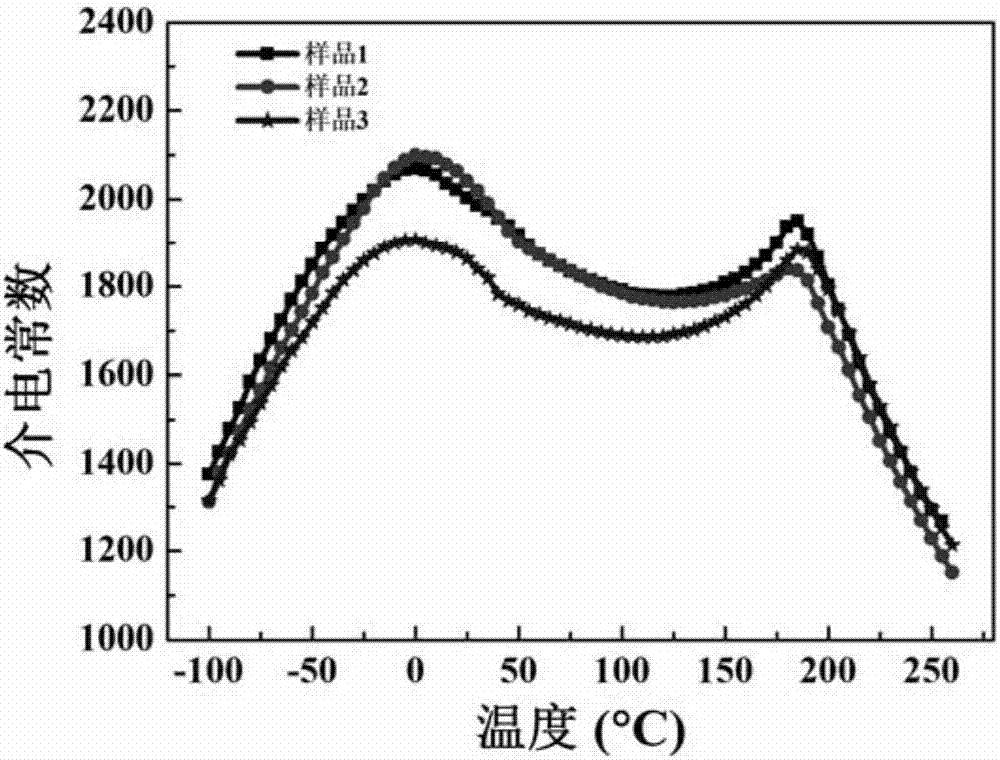

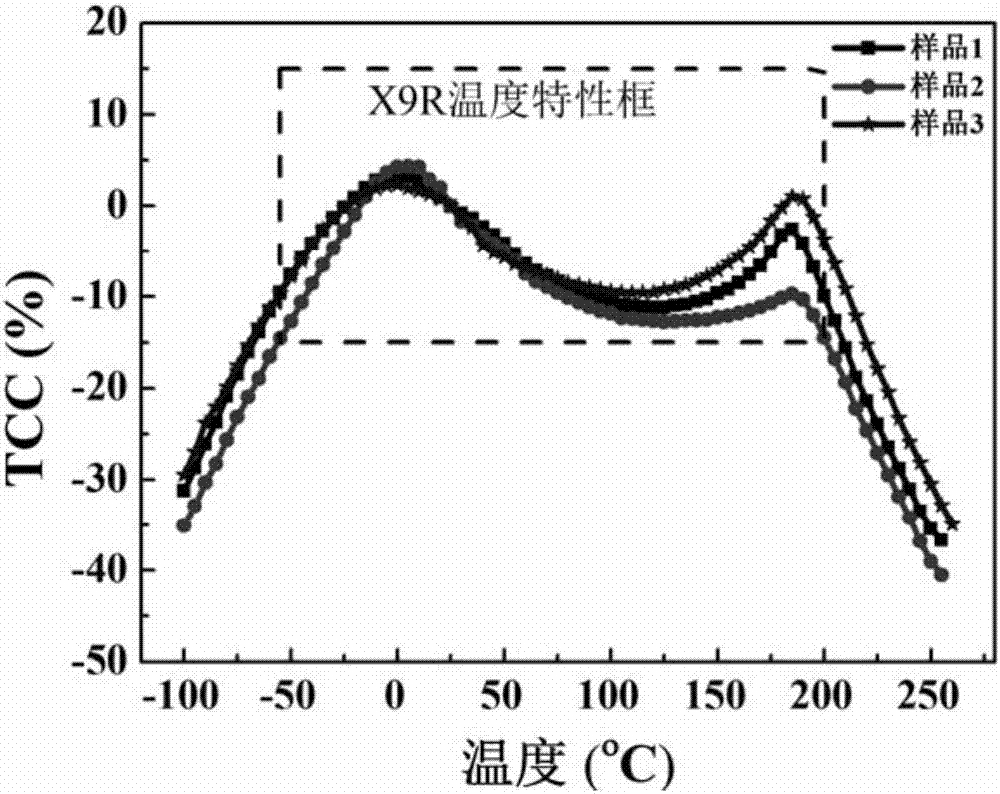

A technology of ceramic capacitors and dielectric materials, applied in the direction of fixed capacitor dielectrics and components of fixed capacitors, etc., can solve the problems of limited application, decrease of dielectric constant, influence on temperature stability of MLCC, etc., and achieve low cost and high dielectric constant. , the effect of broadening the temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、X9

[0046] Example 1, Preparation and performance testing of X9R type anti-reduction ceramic capacitor dielectric material

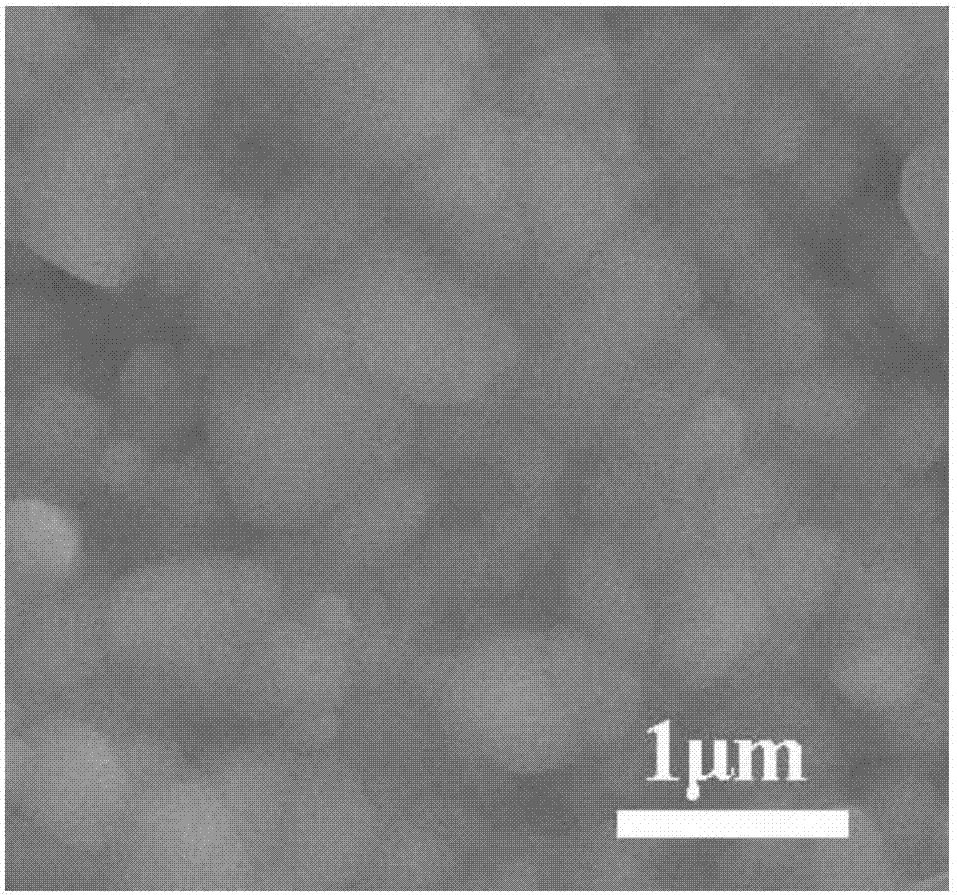

[0047] Chemically pure Bi 2 o 3 、Na 2 CO 3 and TiO 2 Weigh and mix according to the molar ratio of 1:1:4, use ethanol as the ball milling medium (according to 1g total raw material: 10ml ethanol), ball mill for 24 hours, dry in a blast drying oven at 70°C for 12 hours, and use a 100-mesh sieve Sieve into a crucible and pre-fire at 900°C for 3h to obtain Bi 0.5 Na 0.5 TiO 3 (Chinese name: sodium bismuth titanate) powder;

[0048] BaTiO with an average particle size of 50 nm 3 (Chinese name: barium titanate) and the obtained sodium bismuth titanate powder were weighed and mixed according to the molar ratio of 9:1, ball milled with deionized water for 24 hours, dried in a blast drying oven at 100°C for 12 hours, and Sieve through a 100-mesh sieve into a crucible, pre-calcine at 1050°C for 8 hours to obtain barium titanate-sodium bismuth titanate (0.90B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com