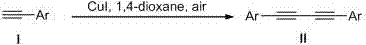

Preparation method of 1,4-disubstituted-1,3-butadiyne

A diacetylene and disubstituted technology, applied in the field of organic synthesis, to achieve the effects of high yield, low production cost and easy source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

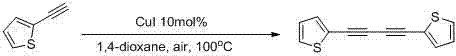

Examples

Embodiment 1-10

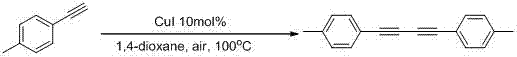

[0028] Example 1-10 Optimization of reaction conditions

[0029] Using phenylacetylene as the raw material for the reaction, the reaction was carried out under air conditions. The effects of different catalysts, solvents and other reaction conditions on the reaction effect were explored, and representative examples 1-10 were selected. The results are shown in Table 1:

[0030]

[0031] Table I:

[0032] Example

Catalyst (mol%)

T ( o C)

Yield (%)

1

CuI(10 mol %)

DMSO

100

45

2

CuI(10 mol %)

DMF

100

37

3

CuI(10 mol %)

MeOH

100

12

4

CuI(10 mol %)

DCM

100

5

5

CuI(10 mol %)

Dioxane

100

93

6

CuI(10 mol %)

Dioxane

60

71

7

CuI(20 mol %)

Dioxane

100

95

8

CuCl(10 mol %)

Dioxane

100

63

9

CuBr(10 mol %)

Dioxane

100

72

10

CuOTf(10 mol %)

Dioxane

100

56

[0033] The basic reaction conditions are as follows: 0.4 mmol of phenylacetylene, 2 mL of solvent, and reaction time of 12 hours.

[0034] Taking Example 5 as an example, the specific operation is as follows: add 40.8 mg (0.4 mmol) ...

Embodiment 6

[0036] The difference between Example 6 and Example 5 lies in the reaction temperature. From Example 6, it can be seen that when the reaction temperature drops to 60°C, the target product 1,4-diphenyl-1,3-butadiyne is The yield dropped to 71% accordingly.

Embodiment 7

[0037] The difference between Example 7 and Example 5 lies in the amount of catalyst added. It can be seen from Example 7 that when the amount of catalyst added is 20 mol %, the target product 1,4-diphenyl-1,3- The yield of diacetylene is not significantly improved. From the perspective of production cost, the present invention selects 10 mol% of the catalyst as the optimal feeding amount.

[0038] Examples 8-10 further screened other monovalent copper catalysts, and the results showed that the catalytic effects of cuprous chloride, cuprous bromide and CuOTf on the reaction were not as good as cuprous iodide.

[0039] Taking the reaction conditions of Example 5 as the optimal conditions, the substrate expansion reaction was carried out, and a series of 1,4-disubstituted-1,3-butadiyne compounds were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com