High-frequency water jet turbine drilling tool

A technology of turbo drilling tool and water jet, which is applied to drilling with liquid/gas jet, drilling equipment, earth-moving drilling, etc., can solve the problems of high production cost and complex structure, and achieves reduction of drilling cost, improvement of construction efficiency and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

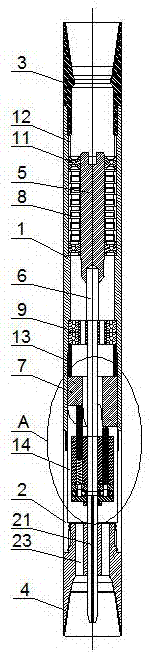

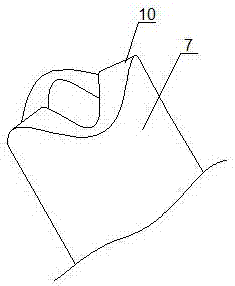

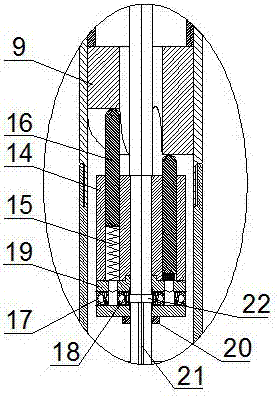

[0021] The high-frequency water jet turbodrill consists of an upper housing 1, a lower housing 2, an upper joint 3, a lower joint 4, a turbine shaft 5, a main shaft 6, a cylindrical cam 7 and a booster device, and one end of the upper housing is threaded The upper joint 3 is installed, the other end of the upper housing 1 is threaded with the lower housing 2, the end of the lower housing 2 is threaded with the lower joint 4, the upper housing 1 is equipped with a turbine shaft 5 through a turbine assembly 8, and the turbine Assembly 8 includes a turbine rotor and a turbine stator. Centralizing bearings 11 are installed on the turbine shafts 5 at both ends of the turbine assembly 8 ; a turbine shaft retaining ring 12 is arranged between the upper joint 3 and the centralizing bearings 11 .

[0022] A main shaft 6 is installed on one side of the turbine shaft 5 through a main shaft bearing 9, and an overflow hole is arranged on the main shaft bearing 9. One end of the main shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com