Capillary electrochromatography enzyme microreactor based on functionalized graphene and preparation method thereof

A technology of capillary electrochromatography and carboxylated graphene, applied in chemical instruments and methods, enzyme production/bioreactors, biochemical equipment and methods, etc., can solve the problems of complex preparation process, poor separation effect and high production cost , to achieve the effect of simple operation steps, good fixing effect and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

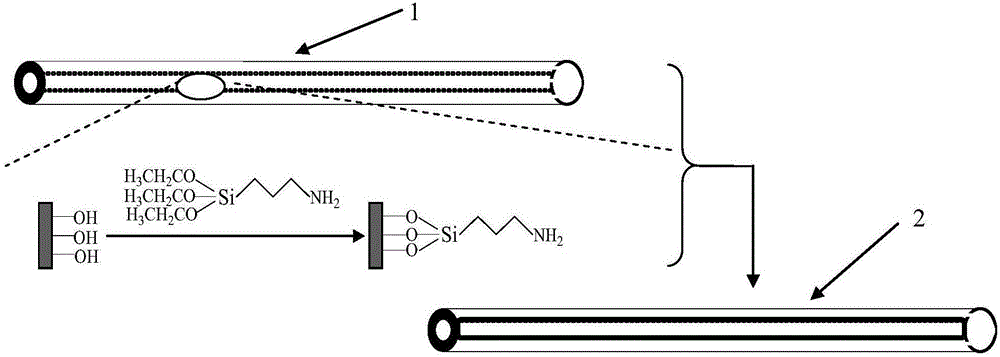

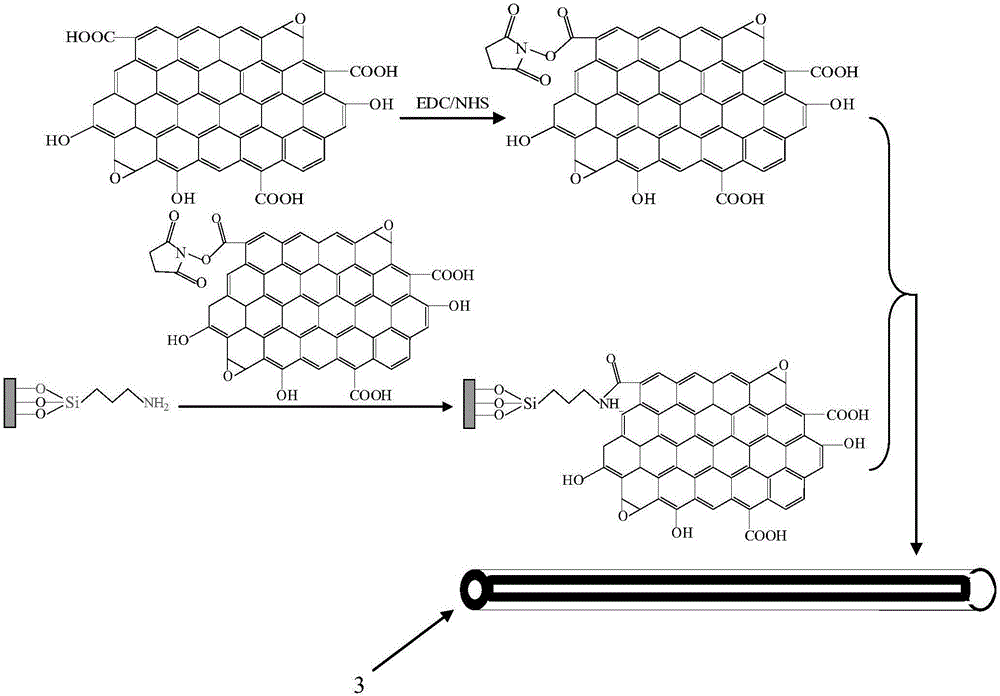

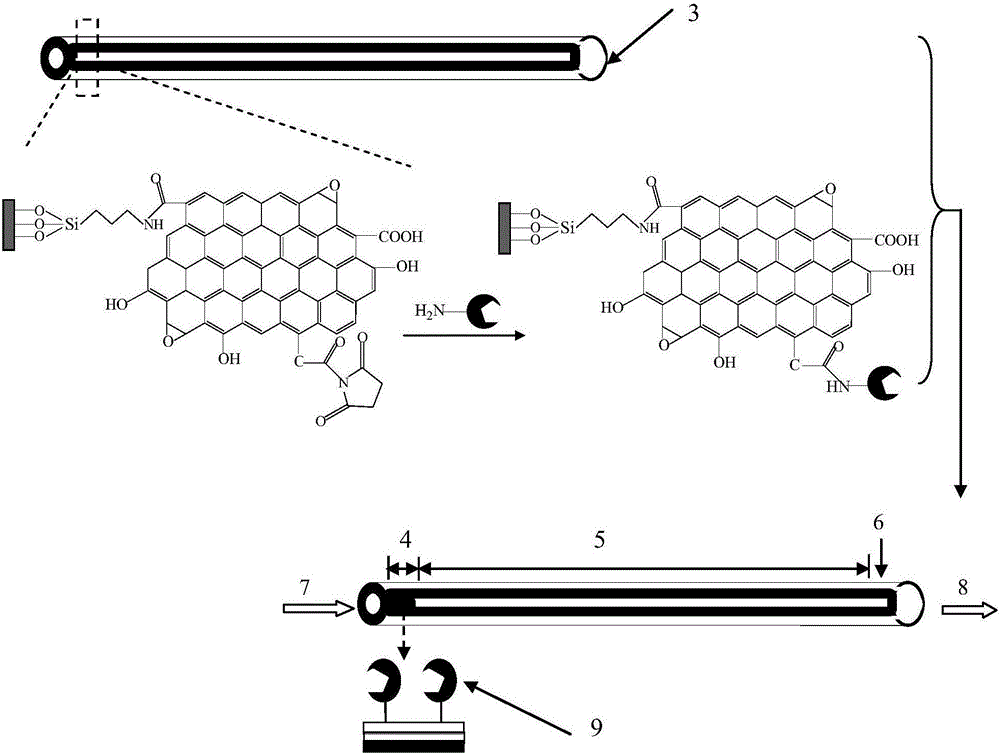

[0059] Capillary electrochromatographic enzyme microreactor preparation method based on functionalized graphene, such as Figure 1-Figure 3 As shown, the specific steps are:

[0060] (1) Pretreatment of the capillary: the inner wall of the capillary is rinsed with 1mol / L sodium hydroxide, deionized water, 0.1mol / L hydrochloric acid, and deionized water for 30 minutes respectively;

[0061] (2) Preparation of capillary electrochromatography of graphene matrix: after blowing dry with nitrogen, feed 5% ethanol solution of 3-aminopropyl-tri(methoxy)-silane to rinse for 10min, so that the inner surface of capillary is bonded with silane Chemical reagent; wash with ethanol for 10min, blow dry with nitrogen; take 2mL of graphene oxide solution with a concentration of 0.5mg / mL, ultrasonicate for 30min (power 100w), add 4mg of carbodiimide (EDC) and 2mg of N-hydroxysuccinate Imide (NHS) activates the carboxyl groups on the graphene oxide, and after vortex shaking for 10 minutes, it is...

Embodiment 2

[0066] Capillary electrochromatographic enzyme microreactor preparation method based on functionalized graphene, such as Figure 1-Figure 3 As shown, the specific steps are:

[0067] (1) Pretreatment of the capillary: the inner wall of the capillary is rinsed with 1mol / L sodium hydroxide, deionized water, 0.1mol / L hydrochloric acid, and deionized water for 30 minutes respectively;

[0068] (2) Preparation of capillary electrochromatography of graphene matrix: after blowing dry with nitrogen, feed 1% ethanol solution of 3-aminopropyl-tri(ethoxy)-silane to rinse for 30min, so that the inner surface of capillary is bonded with silane Chemical reagent; wash with ethanol for 10min, blow dry with nitrogen; take 5mL of graphene oxide solution with a concentration of 5mg / mL, ultrasonicate for 60min (power 150w), add 6mg of carbodiimide (EDC) and 3mg of N-hydroxysuccinyl Imine (NHS) activates the carboxyl groups on the graphene oxide, vortexed for 10 minutes, and rinsed in the capilla...

Embodiment 3

[0073] Capillary electrochromatographic enzyme microreactor preparation method based on functionalized graphene, such as Figure 1-Figure 3 Shown:

[0074] The specific steps are:

[0075] (1) Pretreatment of the capillary: the inner wall of the capillary is rinsed with 1mol / L sodium hydroxide, deionized water, 0.1mol / L hydrochloric acid, and deionized water for 30 minutes respectively;

[0076](2) Preparation of capillary electrochromatography of graphene matrix: after blowing dry with nitrogen, feed 3% ethanol solution of 3-aminopropyl-tri(ethoxy)-silane to rinse for 20min, so that the inner surface of capillary is bonded with silane Chemical reagent; rinse with ethanol for 10min, dry with nitrogen; take 5mL of carboxylated graphene solution with a concentration of 2mg / mL, ultrasonic 20min (power 200w), add 5mg of EDC and 2.5mg of NHS to activate the carboxyl group on the carboxylated graphene , after vortex shaking for 10 minutes, pass into the capillary and rinse for 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Michaelis constant | aaaaa | aaaaa |

| Michaelis constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com