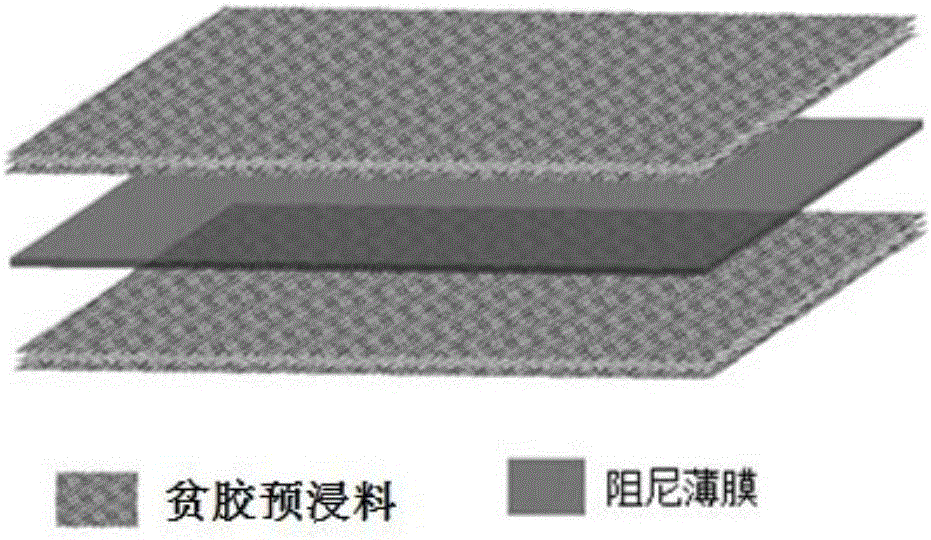

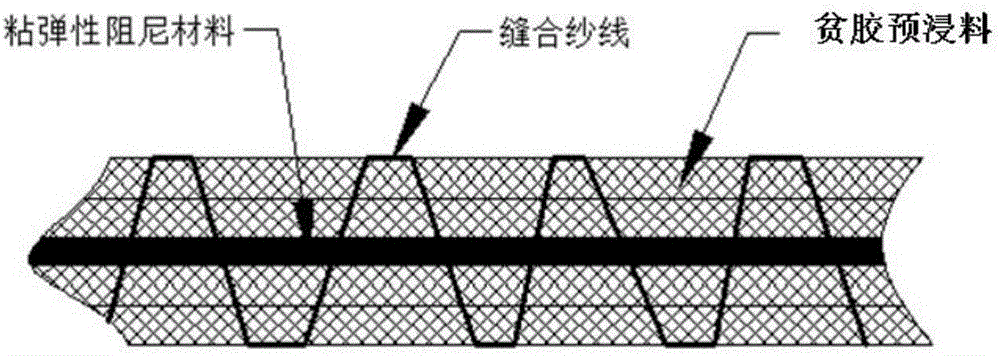

Embedded co-curing stitch damping thin film composite material and manufacturing process thereof

A film composite material and manufacturing process technology, which is applied in the field of embedded co-cured suture damping film composite materials and its manufacturing process, can solve the problems of difficult control of the geometric dimension accuracy of resin nails or resin strips, aging of damping materials, structural damping performance and load bearing Capability loss and other issues can be improved to achieve the effect of improving interlayer shear resistance and out-of-plane tensile capacity, enhancing vibration energy consumption, and improving dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

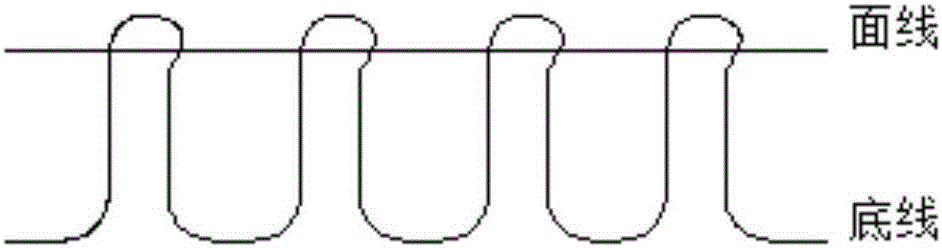

Method used

Image

Examples

preparation example Construction

[0081] The preparation process of the mixed rubber: mix the raw rubber hydrogenated nitrile rubber (HNBR4367) on the open mill, add zinc oxide, stearic acid, accelerator CZ, anti-aging agent N445, and then add antioxidant 1010, reinforcement Agent carbon black N220, finally add accelerator TMYD, sulfur S, tap the rubber back and forth 3 times, adjust the roller distance to the minimum, thin pass 4 times, adjust the roller distance to about 3mm, mix evenly and then release the sheet; place the rubber mixture for 4 Hours and above, back refining it for 5 minutes, thin pass 4-5 times, and press the mixed rubber into thin sheets.

[0082] The production process of the damping rubber solution: measure the solvent according to the volume ratio of the rubber compound and the organic solvent at 1:4, use gasoline or tetrahydrofuran as the organic solvent, place the cut rubber compound fragments in the organic solvent, and place them in a sealed place in a cool and ventilated place For ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com