A kind of synthetic method of inorganic perovskite nanosheet

A synthesis method and nanosheet technology, applied in inorganic chemistry, nanotechnology, chemical instruments and methods, etc., can solve the problems of complex synthesis technology, low yield, harsh experimental conditions, etc., and achieve strong controllability and high yield. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

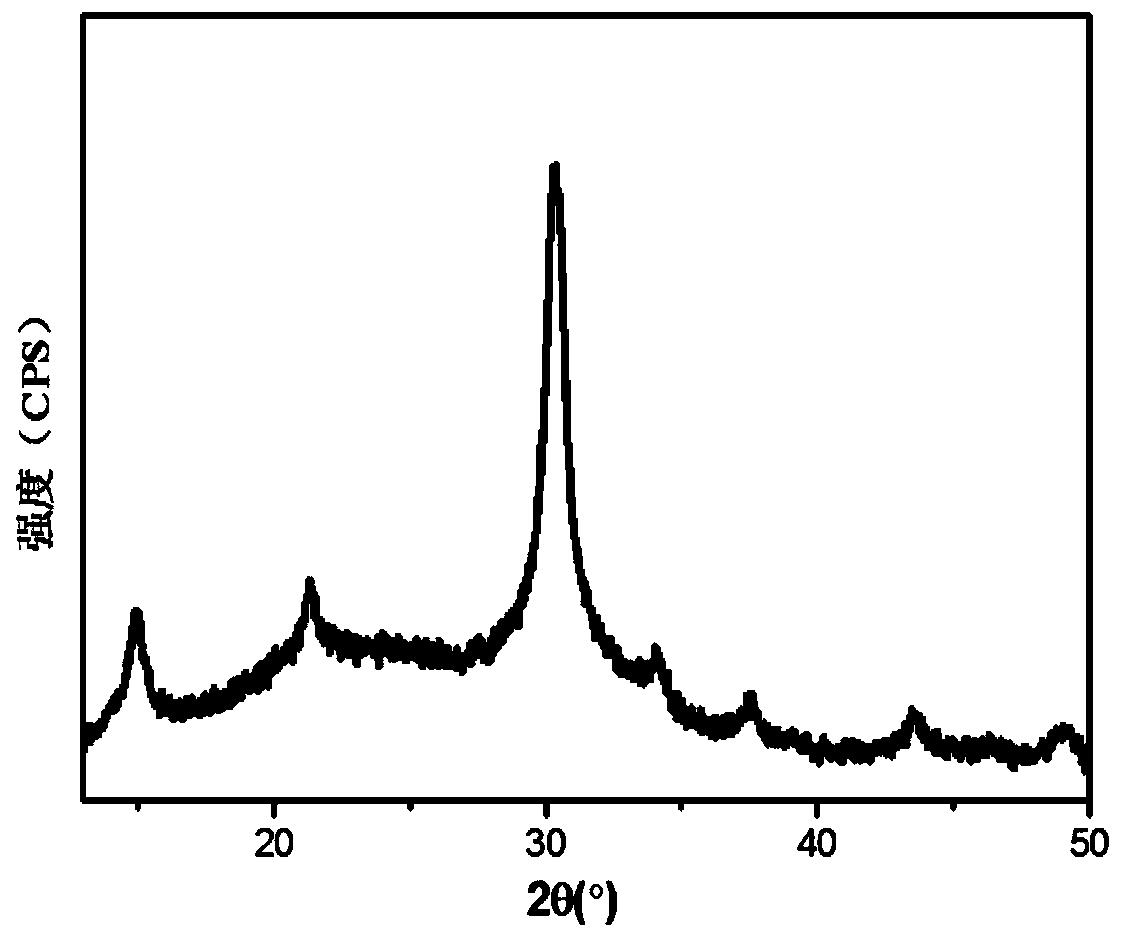

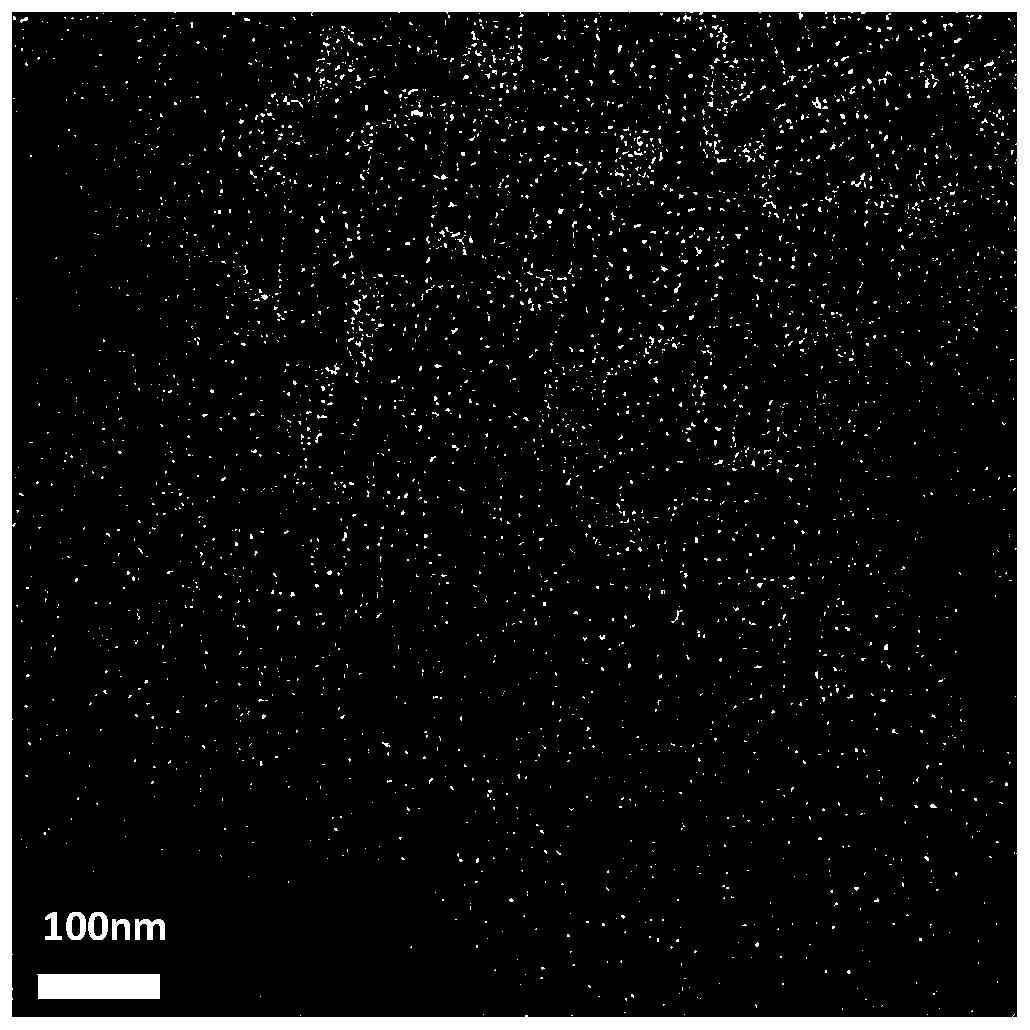

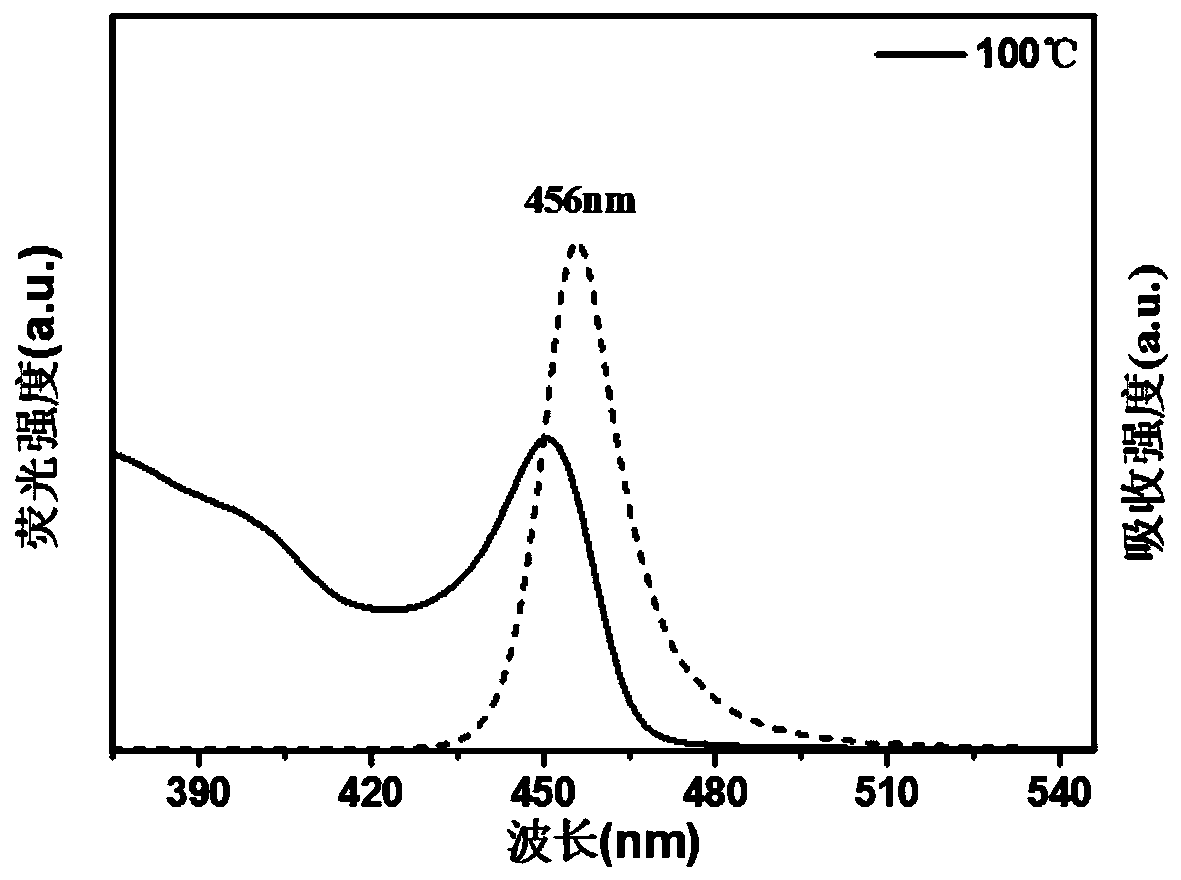

Embodiment 1

[0039] Step 1. Weigh 1.8 mmol of cesium carbonate and add it to a three-necked flask containing 21 mL of octadecene and 3.0 mL of oleic acid, stir at 147°C for 17 minutes to completely dissolve cesium carbonate, and then naturally cool to room temperature to form a precursor of cesium solution.

[0040] Step 2. Weigh 2.0mmol lead bromide and add it to a three-necked flask containing 3.0mL oleic acid, 3.0mL oleylamine and 21mL octadecene, stir at 116°C for 23min to completely dissolve the lead bromide, then cool naturally to At room temperature, a precursor solution of lead bromide is formed.

[0041] Step 3. Measure 2.4 mL of the solution obtained in step 1 and add it into the three-necked flask in step 2, mix well and ultrasonicate at room temperature for 15 min.

[0042] Step 4. Place the mixed solution obtained in Step 3 in a reaction kettle, heat and react at a heating temperature of 100° C. for 60 minutes, and cool down to room temperature naturally after the reaction. ...

Embodiment 2

[0047] Change the cesium carbonate add-on in step 1 in embodiment 1 to 2.4mmol, and other operations are all the same as in embodiment 1, and the obtained CsPbBr 3 Nano sheet is the same as embodiment 1.

Embodiment 3

[0049] Change the amount of lead bromide in step 2 in embodiment 1 to 2.7mmol, and other operations are the same as in embodiment 1, and the obtained CsPbBr 3 Nano sheet is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com