Fresh-keeping film and preparation method thereof

A technology of fresh-keeping film and barrier coating, which is applied in the field of fresh-keeping film and its preparation, can solve the problems of insufficient water vapor and air barrier ability, unfriendly human body and environment, poor compactness of fresh-keeping film, etc., and achieve good anti-mold and bactericidal effect, Guaranteed preservation effect, good ability to block water vapor and air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

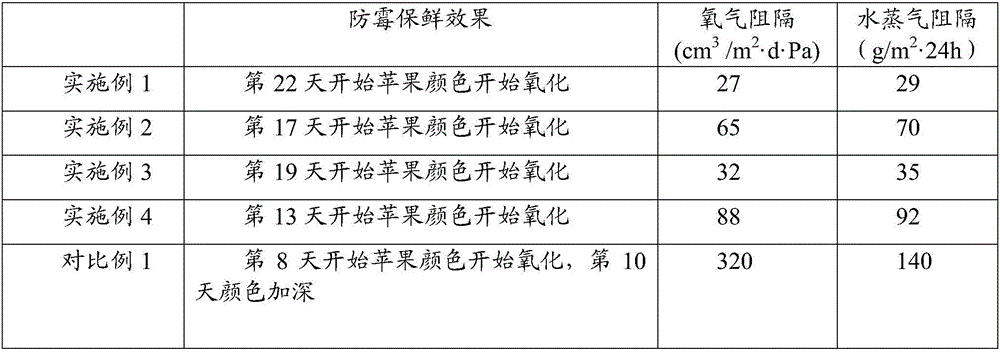

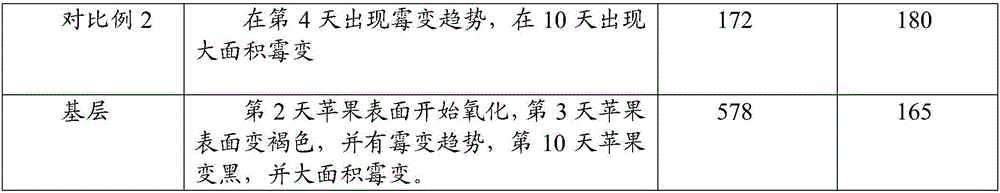

Examples

preparation example Construction

[0033] A method for preparing a plastic wrap according to an embodiment of the present invention includes the following steps S1 to S3:

[0034] S1. Acquiring the base layer, the base layer includes the opposite first surface and the second surface;

[0035] S2. Coating an anti-mildew coating on the first surface.

[0036] S3. Coating a barrier coating on the second surface to obtain a preservative film.

[0037] Optionally, the base layer is polyethylene terephthalate and / or polyamide, the antifungal coating includes 65% to 85% resin and 15% to 35% antifungal agent, and the barrier coating includes 5% to 40% % polyvinyl alcohol, 5% to 25% agar, 0.05% to 5% borax, 0.05% to 5% boric acid and 30% to 85% water. It can be understood that the specific types of the base layer, the anti-mold coating and the barrier coating are not limited thereto, and the existing preservative film base layer, the anti-mold coating for anti-mold and sterilization and the barrier coating for blockin...

Embodiment 1

[0066] The base layer is obtained, and the base layer includes the opposite first surface and the second surface.

[0067] After the base layer goes through the unwinding step, apply an antifungal coating on the first side by forward coating, and apply a barrier coating on the second side by reverse coating, with a dry coating weight of 2.2g / m 2 , The coating speed is 100m / min.

[0068] Then smooth the anti-mildew coating and barrier coating with a smoothing brush, and when the smoothing brush is in contact with the anti-mildew coating or barrier coating, it is perpendicular to the contact surface, and the pressure of the smoothing brush is 3kg.

[0069] Use a suspension oven to dry the anti-mold coating and barrier coating on the surface of the base layer. The temperature field from the inlet to the outlet of the suspension oven is 45°C, 110°C, 140°C, 150°C, and 110°C.

[0070] Use at least two heating rollers to carry out hot pressing and flattening from the surface of the ...

Embodiment 2

[0072] The preparation method is basically the same as that of Example 1, except that the first surface and the second surface are respectively coated with an antifungal coating and a barrier coating in a forward coating manner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com