Stacking-assembled reinforced paper base as well as preparation method and application thereof

A paper-based, pulp fiber technology, applied in the field of papermaking, to achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

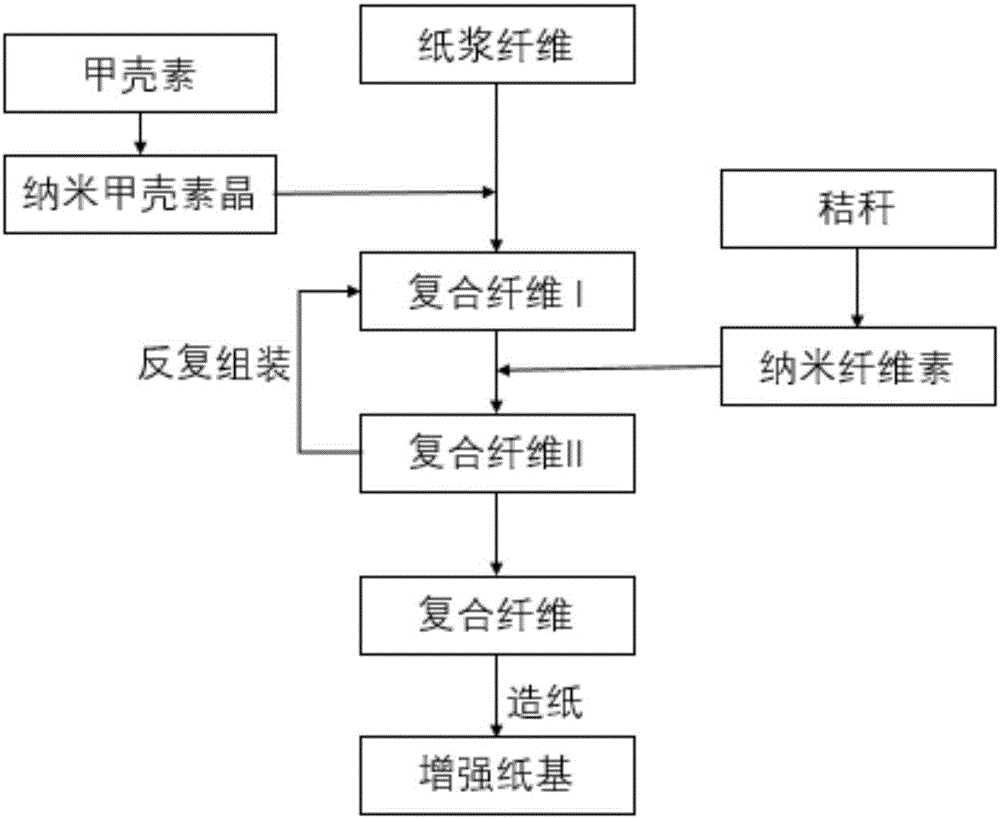

Method used

Image

Examples

Embodiment 1

[0066] A laminated and assembled reinforced paper base, the preparation method of which is as follows:

[0067] (1) The addition amounts of NaBr, TEMPO (2,2,6,6-tetramethylpiperidine-nitrogen-oxide) and NaClO per gram of dry wheat straw were 0.15g, 0.015g and 0.6g, respectively. The concentration is 2wt% (slurry concentration during the TEMPO oxidation reaction of wheat straw), the reaction time is 1.5h, the pH=10.0-10.3, and the stirring speed is 500r / min. Then use a high-pressure homogenizer to process 5 times under a pressure of 20000 psi to obtain nanocellulose, and prepare a suspension with a mass fraction of 0.1%, that is, nanocellulose suspension.

[0068] (2) Chitin is placed in hydrochloric acid with a mass fraction of 12% (the amount of hydrochloric acid with a mass fraction of 12% is 30ml per gram of chitin), heated to 105°C, hydrolyzed at 300r / min for 1h, and then Centrifuge several times under the condition of 10000r / min until the suspension is separated and plac...

Embodiment 2

[0072] (1) The addition amounts of NaBr, TEMPO (2,2,6,6-tetramethylpiperidine-nitrogen-oxide) and NaClO per gram of dry wheat straw were 0.15g, 0.015g and 0.6g, respectively. The concentration is 2wt%, the reaction time is 1.5h, the pH=10.0-10.3, and the stirring speed is 500r / min. Then use a high-pressure homogenizer to process 5 times under the pressure of 20000 psi to obtain nanocellulose, and then prepare a suspension with a mass fraction of 0.1%, that is, nanocellulose suspension.

[0073] (2) Chitin is placed in hydrochloric acid with a mass fraction of 12% (the amount of hydrochloric acid is 30ml relative to each gram of chitin), heated to 105°C, hydrolyzed at 300r / min for 1h, and then heated at 10000r / min Conditional centrifugation several times until the suspension is separated and placed in a dialysis bag (molecular weight cut-off of 14,000) to wash to neutrality, and the chitin whiskers are concentrated to a mass fraction of 0.1% using a rotary evaporator to obtain ...

Embodiment 3

[0077] (1) The addition amounts of NaBr, TEMPO (2,2,6,6-tetramethylpiperidine-nitrogen-oxide) and NaClO per gram of dry wheat straw were 0.15g, 0.015g and 0.6g, respectively. The concentration is 2wt%, the reaction time is 1.5h, the pH=10.0-10.3, and the rotation speed is 500r / min. Then use a high-pressure homogenizer to process 5 times under a pressure of 20000 psi to obtain nanocellulose, and prepare a suspension with a mass fraction of 0.1%, that is, nanocellulose suspension.

[0078] (2) Chitin is placed in hydrochloric acid with a mass fraction of 12% (the amount of hydrochloric acid is 30ml relative to each gram of chitin), heated to 105°C, hydrolyzed at 300r / min for 1h, and then heated at 10000r / min Conditional centrifugation several times until the suspension is separated and placed in a dialysis bag (molecular weight cut-off of 14,000) to wash to neutrality, and the chitin whiskers are concentrated to a mass fraction of 0.1% using a rotary evaporator to obtain nano-ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com