Liquid crystal display element

A technology of liquid crystal and components, which is applied in the field of transmission and scattering liquid crystal display components, and can solve problems such as increased power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0348] The following examples are given to illustrate the present invention in more detail, but the present invention is not limited to these examples.

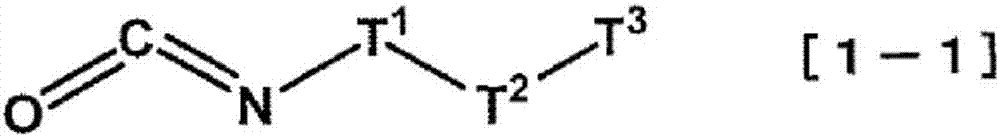

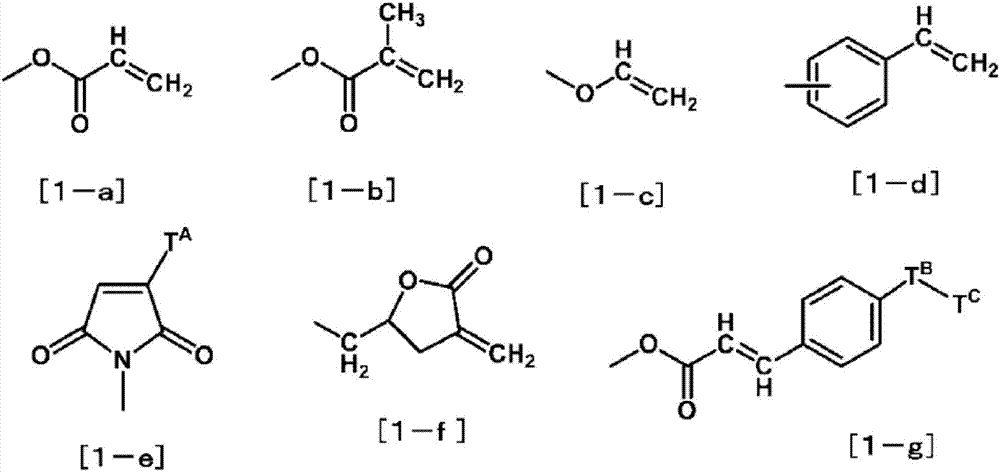

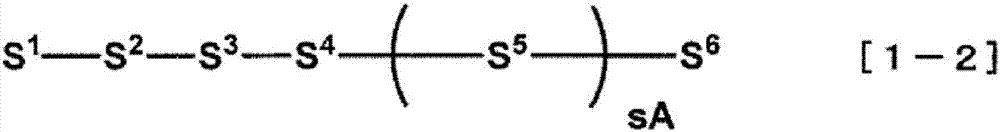

[0349]

[0350] The meanings of the abbreviations of the compounds and the like used below are as follows.

[0351]

[0352]

[0353] (Liquid crystal) L1: MLC-6608 (manufactured by MERCK CORPORATION)

[0354] (polymeric compound)

[0355]

[0356] (photoinitiator)

[0357]

[0358] A1: 1,3-diamino-4-[4-(trans-4-n-heptylcyclohexyl)phenoxy]benzene

[0359] A2: 1,3-diamino-4-[4-(trans-4-n-heptylcyclohexyl)phenoxymethyl]benzene

[0360] A3: 1,3-diamino-4-{4-[trans-4-(trans-4-n-pentylcyclohexyl)cyclohexyl]phenoxy}benzene

[0361] A4: Diamine compound of the following formula [A4]

[0362] A5: 1,3-diamino-4-octadecyloxybenzene

[0363]

[0364] C1: m-xylylenediamine

[0365] C2: 3,5-diaminobenzoic acid

[0366] D1: 1,2,3,4-cyclobutanetetracarboxylic dianhydride

Synthetic example 1

[0395]D2 (6.89g, 27.5mmol), A1 (8.49g, 22.3mmol) and C2 (2.26g, 14.9mmol) were mixed in NMP (38.9g), and after reacting at 50°C for 5 hours, D1 (1.80g , 9.18mmol) and NMP (19.5g), reacted at 40°C for 6 hours to obtain a resin solid content concentration of 25% by mass (hereinafter referred to as C R 25%) of polyamic acid solution (1). The number average molecular weight (Mn) of this polyamic acid was 21300, and the weight average molecular weight (Mw) was 67700.

Synthetic example 2

[0397] After adding NMP to the polyamic acid solution (1) (30.0 g) obtained in Synthesis Example 1 and diluting to 6% by mass, acetic anhydride (2.50 g) and pyridine (2.40 g) were added as an imidation catalyst, The reaction was carried out at 50° C. for 3 hours. This reaction solution was poured into methanol (460 ml), and the obtained precipitate was collected by filtration. This deposit was wash|cleaned with methanol, it dried under reduced pressure at 100 degreeC, and the polyimide powder (2) was obtained. The imidization rate of this polyimide was 55%, Mn was 19,000, and Mw was 50,200.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com