Imidazole salt organic polymer catalyst, preparation method and applications thereof

A technology of polymer and imidazolium salt is applied in the field of imidazolium salt organic polymer catalyst and preparation thereof, and achieves the effects of not easy to run off, easy to recycle and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

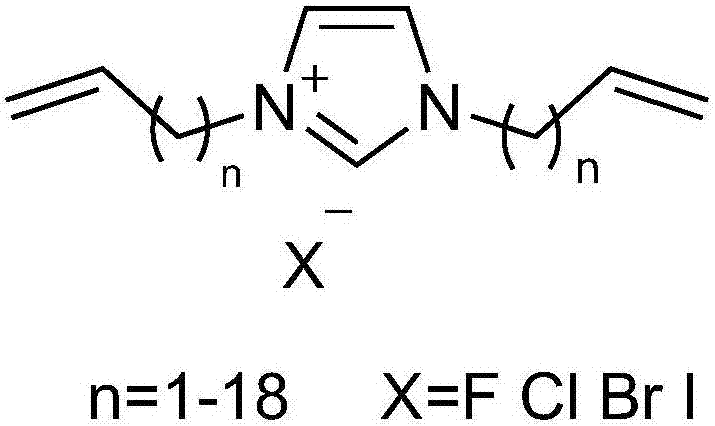

Image

Examples

Embodiment 1

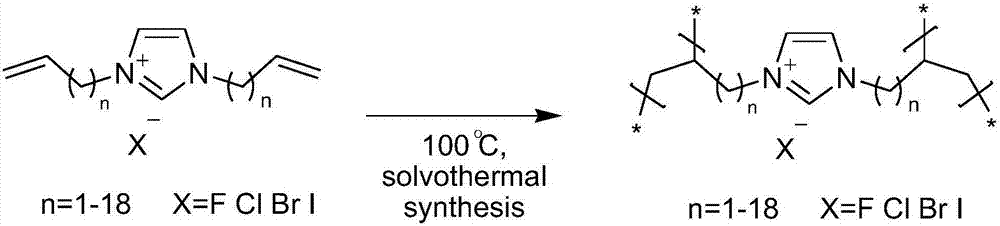

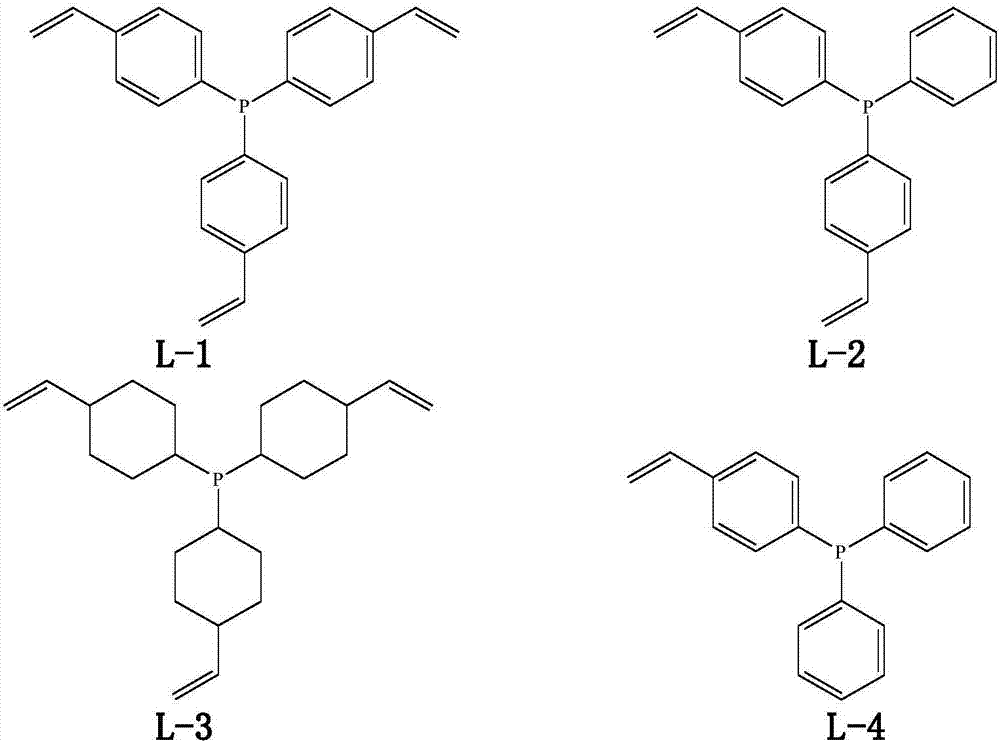

[0052] Under 298K and an inert gas protection atmosphere, 10.0 grams of Vinyl ILBr monomer (attached figure 1 , n=1, X=Br) was dissolved in 100.0ml tetrahydrofuran solvent, while adding 2.5g crosslinking agent tris (4-vinylphenyl) phosphine (L1), adding 1.0 gram of free radical initiator couple to the above solution Azodiisobutyronitrile, stirred for 2 hours. The stirred solution was moved to an autoclave, and polymerized by solvothermal polymerization at 373K and an inert gas atmosphere for 24 hours. After the above polymerized solution is cooled to room temperature, the solvent is removed under vacuum at room temperature to obtain an organic polymer carrier copolymerized with Vinyl ILBr and tris(4-vinylphenyl)phosphine organic monomer. figure 2 It is a schematic diagram of the polymerization technical route of Vinyl ILBr organic mixed polymer carrier. Weigh 70 mg of ZnBr 2 Dissolve in 10.0ml tetrahydrofuran solvent, add 1.0 gram by Vinyl ILBr and three (4-vinylphenyl) ph...

Embodiment 2

[0054] In embodiment 2, except taking by weighing 10.0 grams of crosslinking agent tris (4-vinylphenyl) phosphine (L1), instead of 2.5 grams of crosslinking agent tris (4-vinylphenyl) phosphine (L1), the remaining The catalyst synthesis process is the same as in Example 1.

Embodiment 3

[0056] In Example 3, except that 0.1 gram of free radical initiator azobisisobutyronitrile was weighed instead of 1.0 gram of free radical initiator azobisisobutyronitrile, the rest of the catalyst synthesis process was the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com