Electropolishing fluid and electropolishing method used for preparing magnesium alloy EBSD sample

An electrolytic polishing and magnesium alloy technology, applied in the field of magnesium alloy surface treatment, can solve the problems of uncertain composition ratio of electrolyte, uncertain electrolytic polishing parameters, poor electrolytic polishing effect, etc. The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

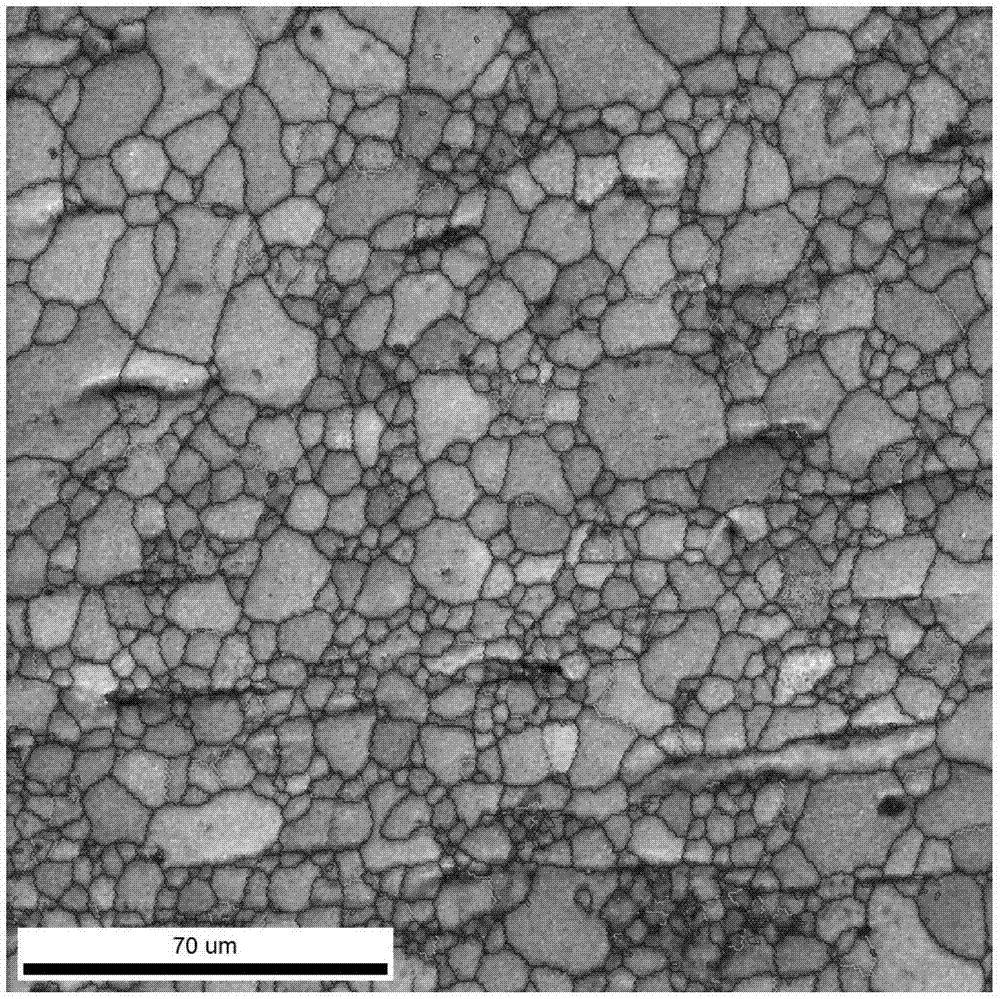

Embodiment 1

[0020] In this embodiment, ZK30 extruded magnesium alloy is used for electropolishing treatment, and the contents of each component in each liter of electropolishing liquid are: n-propanol 100ml, perchloric acid 10ml, deionized water 15ml, hydroxyquinoline 8g, citric acid 70g, sodium thiocyanate 40g, and the balance is dehydrated alcohol. Include the following steps:

[0021] (1) Pour the electrolytic polishing solution into a beaker, the volume of the electrolytic polishing solution is sufficient to fully immerse the sample, and put the beaker into a water tank containing a mixture of ice and water;

[0022] (2) Use the stainless steel sheet as the cathode, connect to the negative pole of the constant current stabilized voltage power supply, and immerse in the bottom of the beaker filled with electrolytic polishing solution, use the magnesium alloy sample as the anode, and connect to the positive pole of the constant current stabilized voltage power supply;

[0023] (3) Befo...

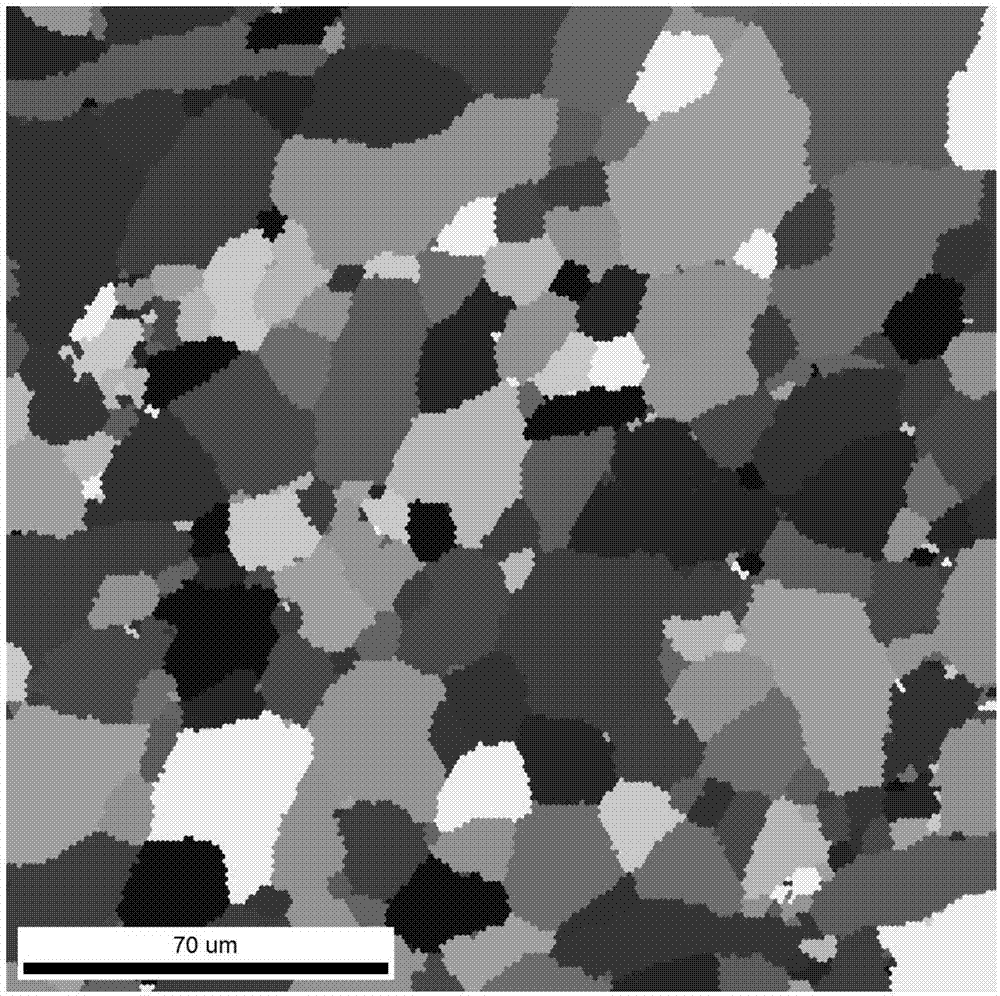

Embodiment 2

[0027] In this embodiment, AZ31 extruded magnesium alloy is used for electropolishing treatment, and the contents of each component in each liter of electropolishing liquid are: n-propanol 95ml, perchloric acid 12ml, deionized water 16ml, hydroxyquinoline 9g, citric acid 65g, sodium thiocyanate 41g, and the balance is dehydrated alcohol. Include the following steps:

[0028] (1) Pour the electrolytic polishing solution into a beaker, the volume of the electrolytic polishing solution is sufficient to fully immerse the sample, and put the beaker into a water tank containing a mixture of ice and water;

[0029] (2) Use the stainless steel sheet as the cathode, connect to the negative pole of the constant current stabilized voltage power supply, and immerse in the bottom of the beaker filled with electrolytic polishing solution, use the magnesium alloy sample as the anode, and connect to the positive pole of the constant current stabilized voltage power supply;

[0030] (3) Befor...

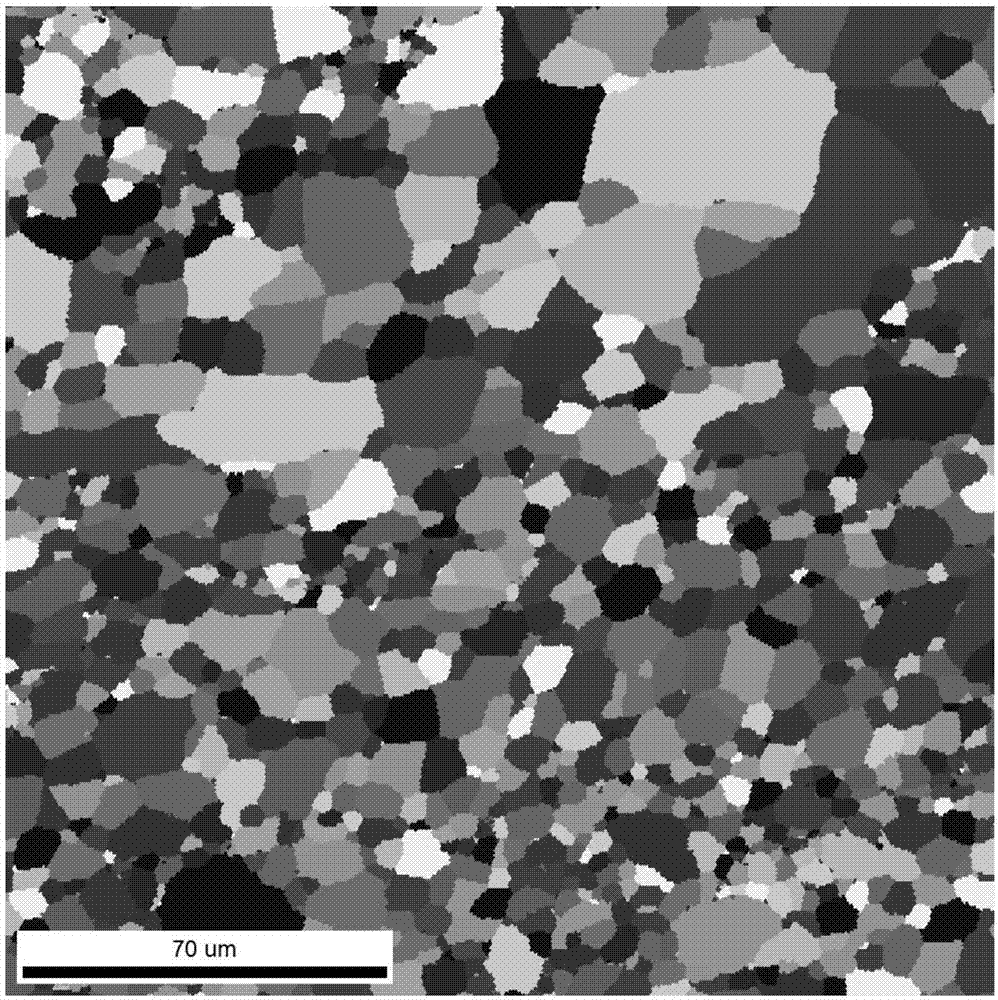

Embodiment 3

[0033] In this embodiment, ZK30-Nd extruded aging state magnesium alloy is used for electrolytic polishing treatment, and the contents of each component in each liter of electrolytic polishing liquid are: n-propanol 100ml, perchloric acid 10ml, deionized water 15ml, hydroxyquinoline 8g , citric acid 70g, sodium thiocyanate 40g, and the balance is dehydrated alcohol. Include the following steps:

[0034] (1) Pour the electrolytic polishing solution into a beaker, the volume of the electrolytic polishing solution is sufficient to fully immerse the sample, and put the beaker into a water tank containing a mixture of ice and water;

[0035] (2) Use the stainless steel sheet as the cathode, connect to the negative pole of the constant current stabilized voltage power supply, and immerse in the bottom of the beaker filled with electrolytic polishing solution, use the magnesium alloy sample as the anode, and connect to the positive pole of the constant current stabilized voltage powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com