A composite ceramic panel for an induction cooker and its preparation

A technology of composite ceramics and induction cooker, which is applied in the field of induction cooker, can solve problems such as the influence of the service life of electrical components inside the induction cooker, the limitation of pot material, and the easy wear and tear of magnetic heating materials, etc., and achieves superior thermal conductivity, which is conducive to mass production and prolongs life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

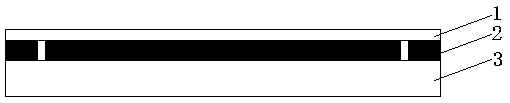

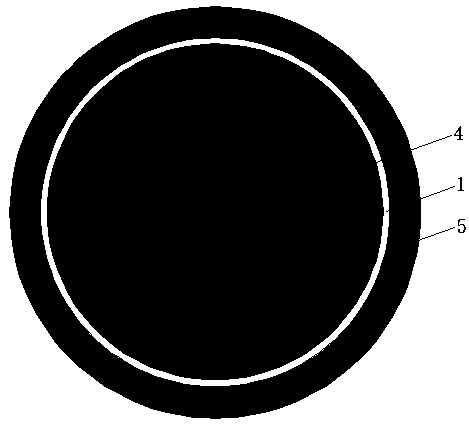

[0026] like figure 1 and figure 2 As shown, a composite ceramic panel for an induction cooker includes a high thermal conductivity ceramic panel 1 , a magnetic heating material 2 and a ceramic bottom plate 3 . According to 10% ferric oxide, 35% carbon fiber, 30% silver powder, 6% ZnO-B 2 o 3 -P 2 o 5 The mass ratio of low-temperature glass powder, 15% terpineol solvent, and 4% ethyl cellulose plasticizer is used to uniformly mix the above materials into a slurry with a certain fluidity; prefabricate a middle one according to the size of the high thermal conductivity ceramic panel 1 A printing plate with a solid circle and a ring outside; the paste is printed on the lower surface of the high thermal conductivity ceramic panel 1 . After drying, it is laminated with a ceramic bottom plate 3 made of glass-ceramics with a thickness of 5mm, and kept in a reducing atmosphere furnace at 620°C for 3 minutes to obtain a central magnetic material film 4 and a magnetic material ring...

Embodiment 2

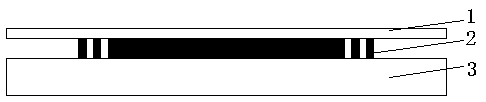

[0028] like image 3 and Figure 4 As shown, a composite ceramic panel for an induction cooker includes a high thermal conductivity ceramic panel 1 , a magnetic heating material 2 and a ceramic bottom plate 3 . According to 20% ferric oxide, 15% carbon fiber, 45% silver powder, 8% ZnO-B 2 o 3 -P 2 o 5 The mass ratio of low-temperature glass powder, 9% terpineol solvent, and 3% ethyl cellulose plasticizer is used to uniformly mix the above materials into a slurry with a certain fluidity; prefabricate a middle one according to the size of the high thermal conductivity ceramic panel 1. Rectangular printing plate with 2 rectangular rings outside; paste printed to 60% Al2O3 + 10% SiC whisker + 30% ZnO-B 2 o 3 -P 2 o 5 On the 1.5mm thick ceramic raw tape of low temperature glass powder, after drying, it is combined with 3 layers of 60% alumina + 40% ZnO-B 2 o 3 -P 2 o 5 Low-temperature glass and ceramic raw tapes with a total thickness of 4.5mm are stacked together, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com