Lithium ion battery electrolyte and lithium ion battery containing electrolyte

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of inability to meet the operation requirements of electric vehicles, restrict the promotion of electric buses, etc., and achieve the effects of reducing battery interface impedance, improving wettability, and improving composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation of lithium-ion battery electrolyte: mix EC, EMC, DEC, and methyl propionate evenly according to the volume ratio of 18 / 40 / 15 / 20, wherein EC, EMC, and DEC account for 59% of the total mass of the electrolyte, and propionic acid Methyl ester accounts for 18% of the total mass of the electrolyte, adding LiPF 6 and lithium bisfluorosulfonyl imide (LiFSI), so that the concentration of the two in the electrolyte is 0.85mol / L and 0.2mol / L respectively, adding VC, 0.5% potassium carbonate and 1.5% of the total mass of the electrolyte 2.0% fluoroethylene carbonate (FEC), that is, to obtain the final electrolyte product.

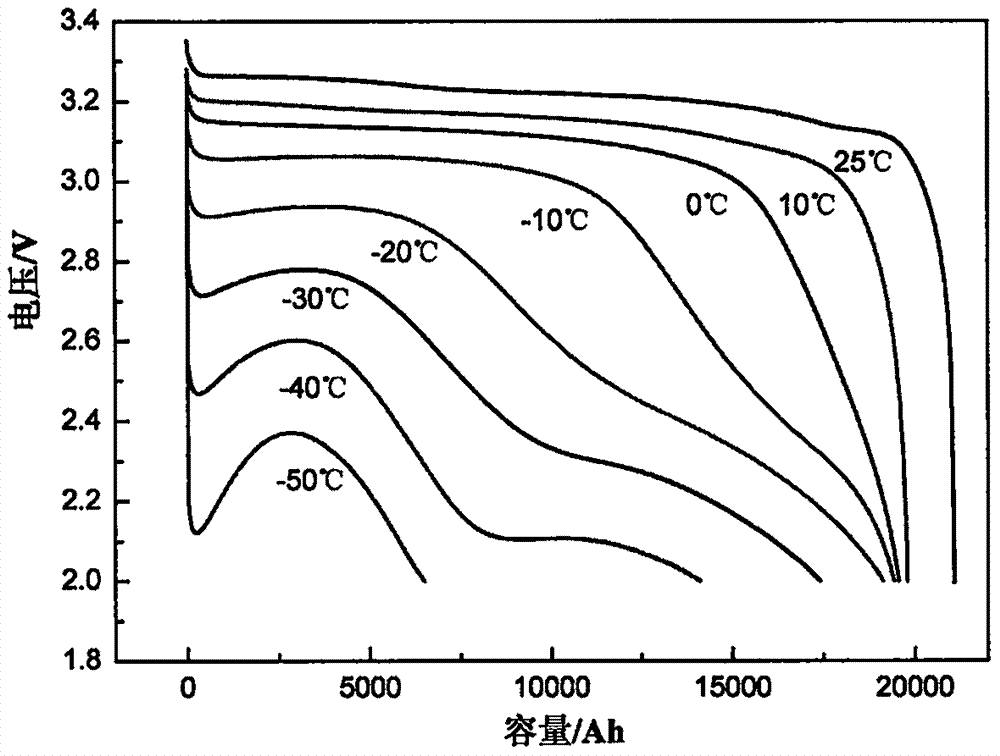

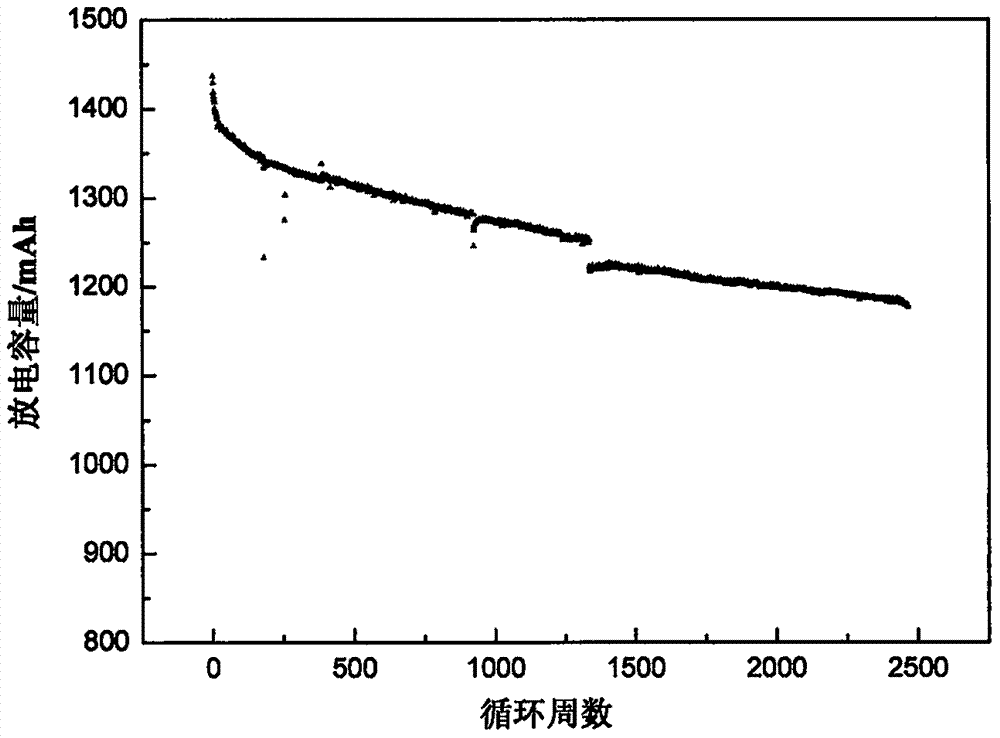

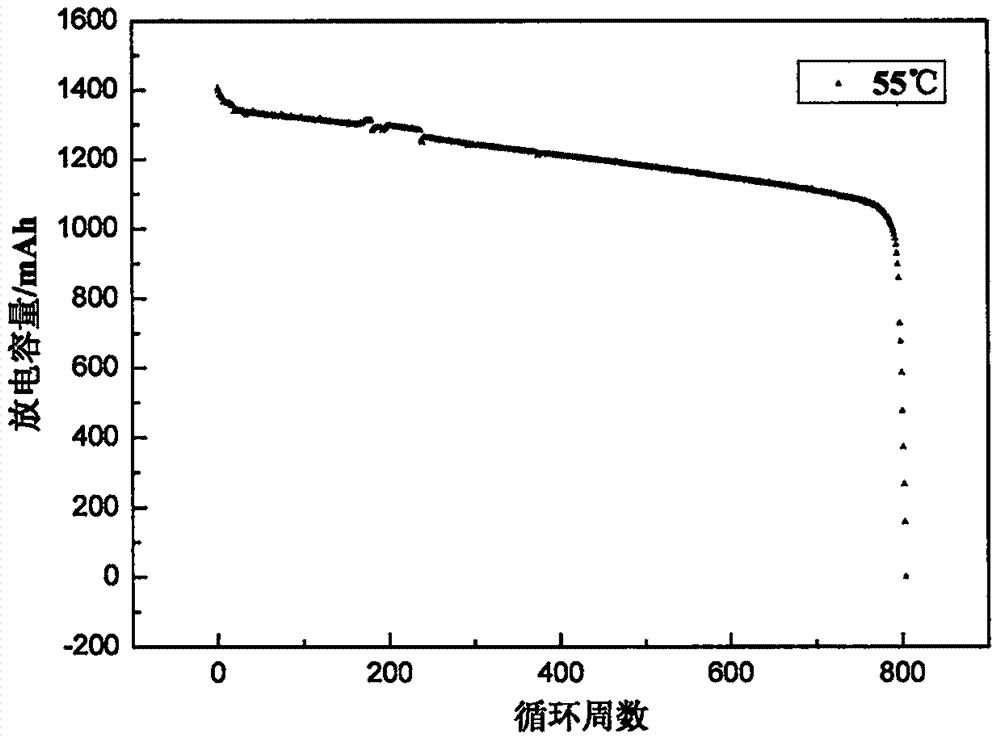

[0043] Preparation of Lithium-Ion Batteries: A known method for preparing lithium-ion batteries was used to prepare 20Ah and 1.4Ah iron phosphate lithium-ion batteries using the electrolyte prepared in this example. Figure 1~3 The discharge curve and cycle life curve of the lithium ion battery of this embodiment are provided. pass Figure 1-3 It...

Embodiment 2

[0045] Preparation of lithium-ion battery electrolyte: Mix EC, EMC, PC, and butyl acetate evenly according to the volume ratio of 15 / 30 / 18 / 40, wherein EC, EMC, and PC account for 51% of the total mass of the electrolyte, and butyl acetate Accounting for 37% of the total mass of the electrolyte, adding LiPF 6 and LiBF 4 , so that the concentrations of the two in the electrolyte are 0.95mol / L and 0.25mol / L respectively, add 1.5% of VC, 0.8% of vinyl sulfate, and 1.0% of 12-crown-4-ether and 0.5% fluorobenzene to obtain the final electrolyte product.

[0046] Preparation of Lithium-Ion Batteries: A known method for preparing lithium-ion batteries was used to prepare 20Ah and 1.4Ah iron phosphate lithium-ion batteries using the electrolyte prepared in this example.

Embodiment 3

[0048] Preparation of lithium-ion battery electrolyte: Mix EC, DMC, DEC, and methyl formate evenly according to the volume ratio of 17 / 35 / 15 / 43, wherein EC, DMC, and DEC account for 48% of the total mass of the electrolyte, and methyl formate Accounting for 39% of the total mass of the electrolyte, adding LiPF 6 and lithium difluorooxalate borate (LiODFB), so that the concentrations of the two in the electrolyte are 0.65mol / L and 0.45mol / L respectively, and 1.0% of vinyl sulfite and 0.5% of ethylene sulfate are added to the total mass of the electrolyte ester, 0.7% of 15-crown-5-ether and 1.0% of dialkyl carbonate to obtain the final electrolyte product.

[0049] Preparation of Lithium-Ion Batteries: A known method for preparing lithium-ion batteries was used to prepare 20Ah and 1.4Ah iron phosphate lithium-ion batteries using the electrolyte prepared in this example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com