A low-cost method for treating coking wastewater

A low-cost technology for coking wastewater, applied in chemical instruments and methods, mining wastewater treatment, water/sewage multi-stage treatment, etc. Treatment costs, saving process operating costs, and meeting the effect of up-to-standard emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

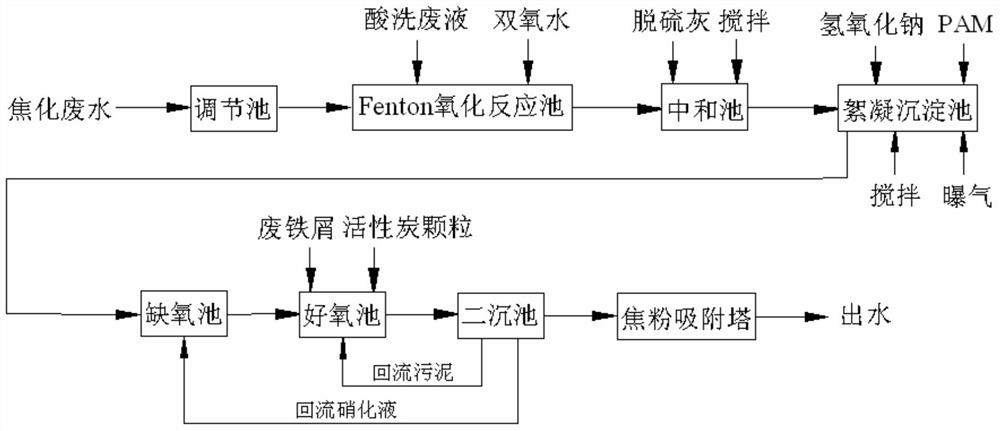

Image

Examples

Embodiment 1

[0018] The coking wastewater in the adjustment tank is pumped into the Fenton oxidation reaction tank. The reaction tank adopts intermittent operation, and pickling waste liquid is added while stirring to control the pH of the wastewater in the Fenton oxidation tank to 2.0; then add hydrogen peroxide solution to make the concentration To reach 1300ppm, the oxidation reaction time is controlled to be 1.5h under stirring; the effluent of the Fenton oxidation reaction tank flows into the neutralization tank, and desulfurization ash is added to the neutralization tank while stirring, and the pH of the wastewater is controlled to be 7.0; the neutralization tank’s The effluent flows into the flocculation sedimentation tank. Add 15% NaOH lye and 4ppm flocculant PAM to the flocculation sedimentation tank while stirring, control the pH of the wastewater to 9.0, and aerate the wastewater while stirring. After stirring for 15 minutes Stop stirring and aerating the wastewater, and let it s...

Embodiment 2

[0022]The coking wastewater in the adjustment tank is pumped into the Fenton oxidation reaction tank. The reaction tank adopts intermittent operation, and pickling waste liquid is added while stirring to control the pH of the wastewater in the Fenton oxidation tank to 2.5; then add hydrogen peroxide solution to make the concentration To reach 1400ppm, the oxidation reaction time is controlled to be 2.0h under stirring; the effluent of the Fenton oxidation reaction tank flows into the neutralization tank, and desulfurization ash is added to the neutralization tank while stirring, and the pH of the wastewater is controlled to be 7.5; The effluent flows into the flocculation sedimentation tank. Add 20% NaOH lye and 6ppm flocculant PAM to the flocculation sedimentation tank while stirring, control the pH of the wastewater to 9.5, and aerate the wastewater while stirring. After stirring for 18 minutes Stop stirring and aerating the wastewater, and let it settle for 35 minutes. The ...

Embodiment 3

[0026] The coking wastewater in the adjustment tank is pumped into the Fenton oxidation reaction tank. The reaction tank adopts intermittent operation, and pickling waste liquid is added while stirring to control the pH of the wastewater in the Fenton oxidation tank to 3.0; then add hydrogen peroxide solution to make the concentration To reach 1500ppm, the oxidation reaction time is controlled to be 2.5h under stirring; the effluent of the Fenton oxidation reaction tank flows into the neutralization tank, and desulfurization ash is added to the neutralization tank while stirring, and the pH of the wastewater is controlled to be 8.0; the neutralization tank’s The effluent flows into the flocculation sedimentation tank. Add 25% NaOH lye and 8ppm flocculant PAM to the flocculation sedimentation tank while stirring, control the pH of the wastewater to 10.0, and aerate the wastewater while stirring. After the stirring time reaches 20min Stop stirring and aerating the wastewater, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com