Dynamic polymer with hybrid cross-linking network and application

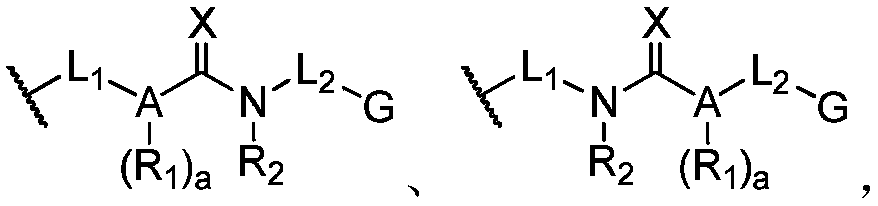

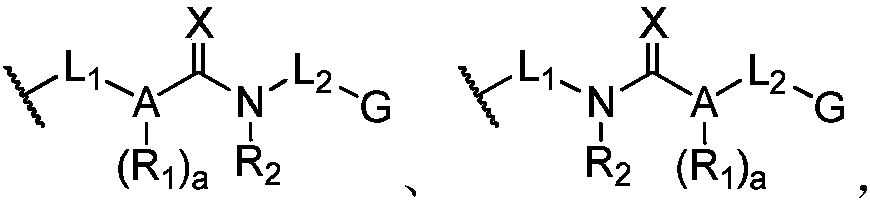

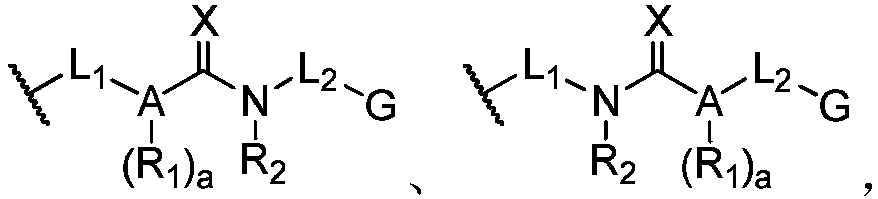

A hybrid cross-linking and cross-linking network technology, applied in the field of dynamic polymers, can solve problems such as performance and application limitations, lack of dynamics, covalent interpenetrating networks cannot perform any repair, etc., to improve toughness, increase toughness, The effect of good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0205] The preparation method of a kind of dynamic polymer ionic liquid gel of the present invention preferably comprises the following steps: the raw material of the dynamic polymer that prepares hybrid cross-linked network is added in ionic liquid, makes the prepared hybrid cross-linked network The mass fraction of the dynamic polymer is 0.5-50%. The covalent cross-linking is carried out by the appropriate means, and after the reaction is completed, it is naturally cooled to form a dynamic polymer gel. The ionic liquids mentioned above are generally composed of organic cations and inorganic anions. The cations are usually alkyl quaternary ammonium ions, alkyl quaternary ions, 1,3-dialkyl substituted imidazolium ions, N-alkyl substituted pyridinium ions, etc. ; Anions are usually halide ions, tetrafluoroborate ions, hexafluorophosphate ions, and CF 3 SO 3 - , (CF3SO 2 ) 2 N - 、C 3 f 7 COO - 、C 4 f 9 SO 3 - 、CF 3 COO - , (CF 3 SO 2 ) 3 C - , (C 2 f 5 SO 2 ...

Embodiment 1

[0215] Mix oligomeric polyvinyl alcohol (PVA) (molecular weight about 500) with a certain amount of methyl isocyanate, use triethylamine as a catalyst, and react in methylene chloride to control the molar number of PVA hydroxyl groups and isocyanate in the reaction. The ratio of the number of moles of acid radicals is about 10:6, and a polyol oligomer with carbamate groups in the side groups is obtained.

[0216] Weigh the reaction material A in parts by weight: 12 parts of the above-mentioned polyol oligomers with carbamate groups, 0.2 parts of 1,4-butanediol, 0.2 parts of dibutyltin dilaurate, 0.2 parts of Sanya Add ethyldiamine, 0.1 part of silicone oil, 6 parts of methylene chloride, and 3.5 parts of water into the container, and stir evenly at a material temperature of 35°C and a stirring speed of 200r / min; reaction material B: 14 parts of toluene di Add the isocyanate into the container, and stir evenly under the condition of material temperature 35°C and stirring speed ...

Embodiment 2

[0219] Using hydroxyethyl acrylate as a monomer and AIBN as an initiator, heat to 60°C for 2 hours to prepare polyhydroxyethyl acrylate through free radical polymerization.

[0220] The obtained polyhydroxyethyl acrylate (molecular weight is about 4000) is mixed with a certain amount of ethyl isocyanate, and triethylamine is used as a catalyst to react in methylene chloride to control the hydroxyl group in the side group of polyhydroxyethyl acrylate during the reaction. The ratio of the number of moles of isocyanate to the number of moles of isocyanate is about 10:8, so that the side groups of polyhydroxyethylacrylate have urethane groups.

[0221] Weigh the reaction material A in parts by weight: 12 parts of the above-mentioned polyol oligomers with urethane groups on the side groups, 0.5 parts of 1,4-butanediol, 0.1 parts of dibutyltin dilaurate, 0.05 parts of Sanya Add ethyldiamine, 0.1 parts of silicone oil, 6 parts of dichloromethane, and 3.5 parts of water into the conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com