Extraction method of casein phosphopeptide

A technology of casein phosphopeptide and sodium casein phosphate, which is applied in the field of biologically active peptides, can solve the problems of increasing the difficulty and production cost of industrial production in the purification steps, and the complicated process of casein phosphopeptide, so as to reduce the difficulty of preparation and reduce the production cost. Effects of cost, many phosphoserine residues, and high calcium holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

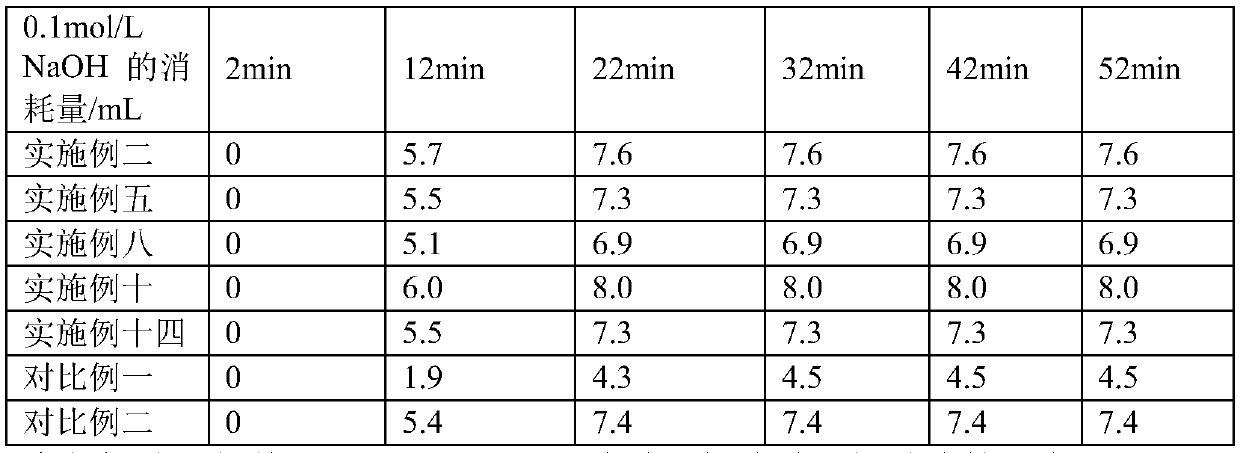

Examples

Embodiment 1

[0030] Embodiment one: casein phosphopeptide extraction method, comprises the following steps:

[0031] Step (1): Add 100Kg of water into the enzymolysis tank, stir at 42°C and 50r / min, then add 33.5Kg of sodium casein phosphate into the enzymolysis tank to obtain a suspension of sodium casein phosphate;

[0032] Step (2): adding compound protease for enzymolysis to obtain a casein phosphopeptide solution; the mass ratio of the compound protease is chymotrypsin:flavor protease:papain=1.5:3:2; enzymatic hydrolysis conditions are: adding compound protease The amount is 0.5% of the mass of casein sodium phosphate, the pH value is 6.8, the reaction temperature is 42°C, the stirring speed is 50r / min, and the reaction time is 6h; step (3): the casein phosphopeptide solution is subjected to high-speed centrifugation in sequence and spray drying to obtain powdered casein phosphopeptides with a CPPs content of ≥85%, a molecular weight of 1000-1750Da, no bitter taste, good water solubil...

Embodiment 2

[0033] Embodiment two: casein phosphopeptide extraction method, comprises the following steps:

[0034] Step (1): Add 100Kg of water into the enzymolysis tank, stir at 45°C and 45r / min, then add 66.5Kg of sodium casein phosphate into the enzymolysis tank to obtain a suspension of sodium casein phosphate;

[0035] Step (2): Add compound protease for enzymolysis to obtain casein phosphopeptide solution; the mass ratio of compound protease is chymotrypsin:flavor protease:papain=3:2:1.5; the enzymolysis condition is: add compound protease The amount is 2.5% of the mass of sodium casein phosphate, the pH value is 7, the reaction temperature is 45°C, the stirring speed is 45r / min, and the reaction time is 5h;

[0036] Step (3): The casein phosphopeptide solution is subjected to high-speed centrifugation and spray drying in sequence to obtain powdered casein phosphopeptides with a CPPs content of ≥85%, a molecular weight of 1000-1750Da, no bitterness, good water solubility, and a mas...

Embodiment 3

[0037] Embodiment three: casein phosphopeptide extraction method, comprises the following steps:

[0038] Step (1): Add 100Kg of water into the enzymolysis tank, stir at 48°C and 55r / min, then add 50Kg of sodium casein phosphate into the enzymolysis tank to obtain a suspension of sodium casein phosphate;

[0039] Step (2): Add compound protease for enzymolysis to obtain casein phosphopeptide solution; the mass ratio of compound protease is chymotrypsin:flavor protease:papain=2:1.5:3; enzymolysis conditions are: add compound protease The amount is 5% of the mass of sodium casein phosphate, the pH value is 7.2, the reaction temperature is 48°C, the stirring speed is 55r / min, and the reaction time is 4h;

[0040] Step (3): The casein phosphopeptide solution is subjected to high-speed centrifugation and spray drying in sequence to obtain powdered casein phosphopeptides with a CPPs content of ≥85%, a molecular weight of 1000-1750Da, no bitterness, good water solubility, and a mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com