Color-changing organic light emitting diode (OLED) device and fabrication method thereof

A device and intermediate layer technology, applied in the field of color-changing OLED devices, can solve the problems of poor stability, reduction, and short device life, and achieve the effects of variable color, high brightness, and good device stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A method for preparing a color-changing OLED device, comprising the following steps:

[0044] Step 1, cleaning and drying the ITO glass 1;

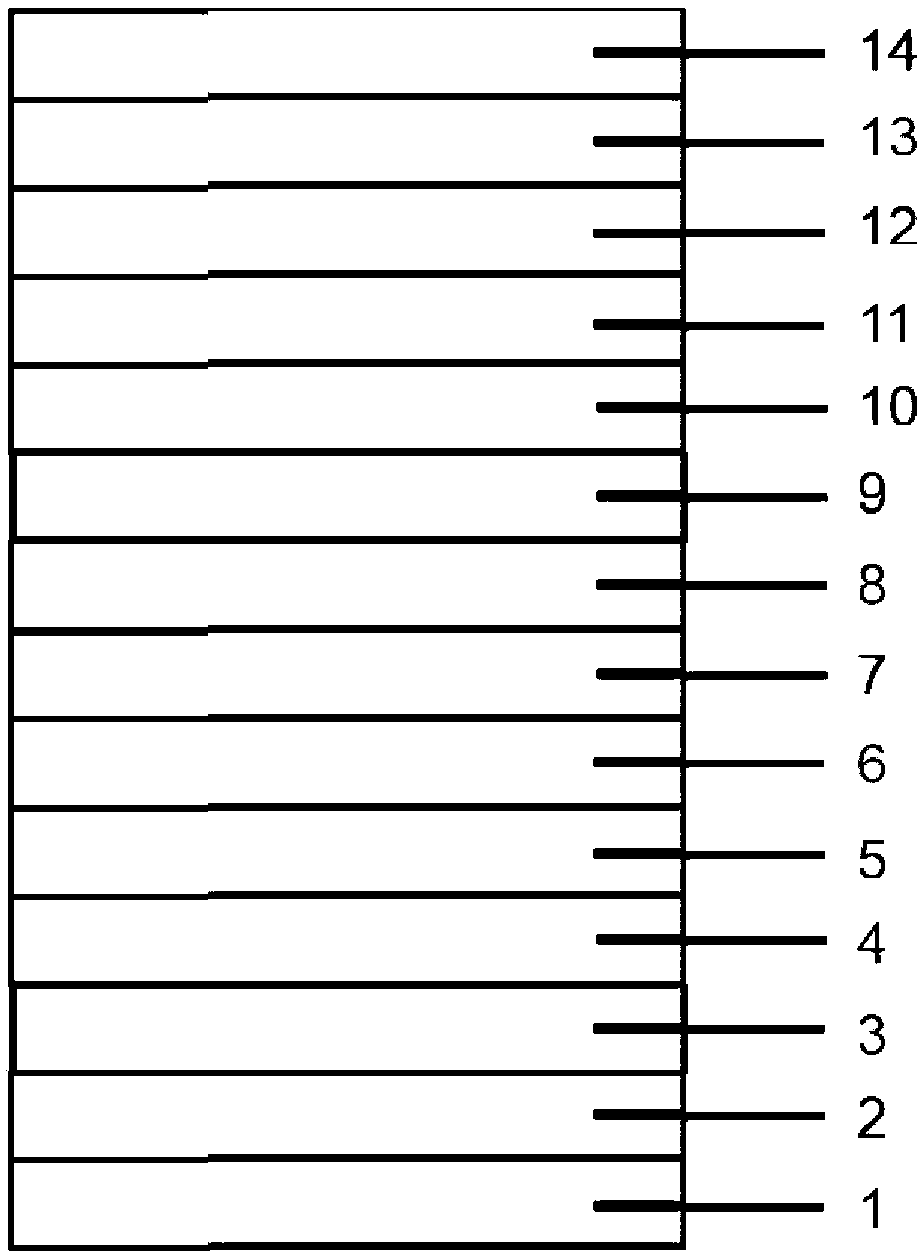

[0045] Step 2, move the ITO glass 1 into the vacuum coating chamber, and sequentially vapor-deposit the first hole injection layer 2, the first hole transport layer 3, the first light-emitting layer 4, and the first electron transport layer 5 on the ITO glass 1 , the first electron injection layer 6, the electron type intermediate layer 7, the hole type intermediate layer 8, the second hole injection layer 9, the second hole transport layer 10, the second light emitting layer 11, the second electron transport layer 13, The second electron injection layer and the cathode electrode 14 form an organic electroluminescent device;

[0046] In step 3, the device prepared in step 2 is packaged in a glove box, and the glove box is a nitrogen atmosphere.

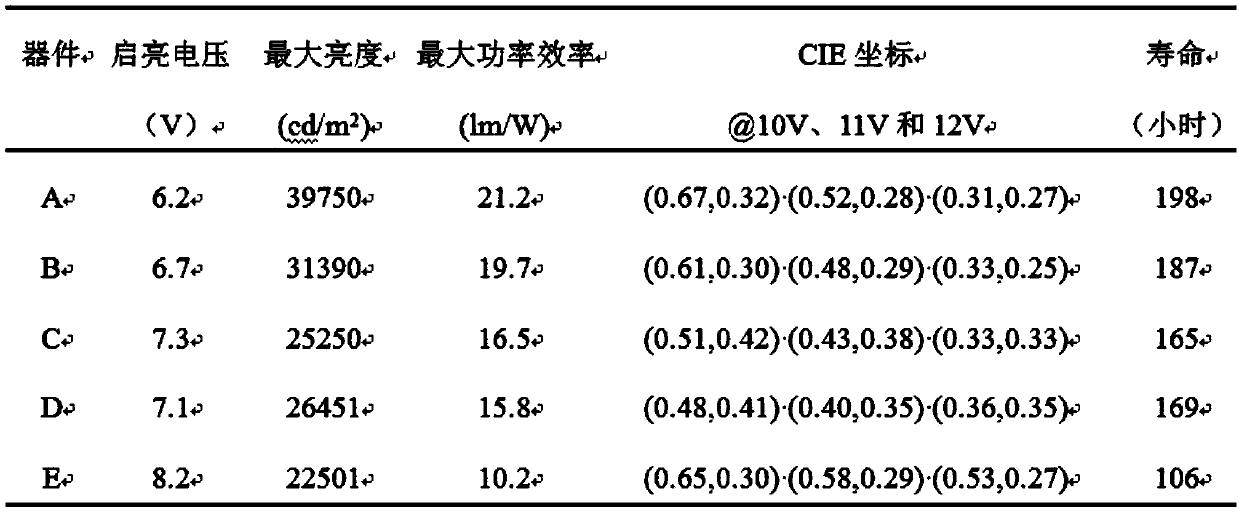

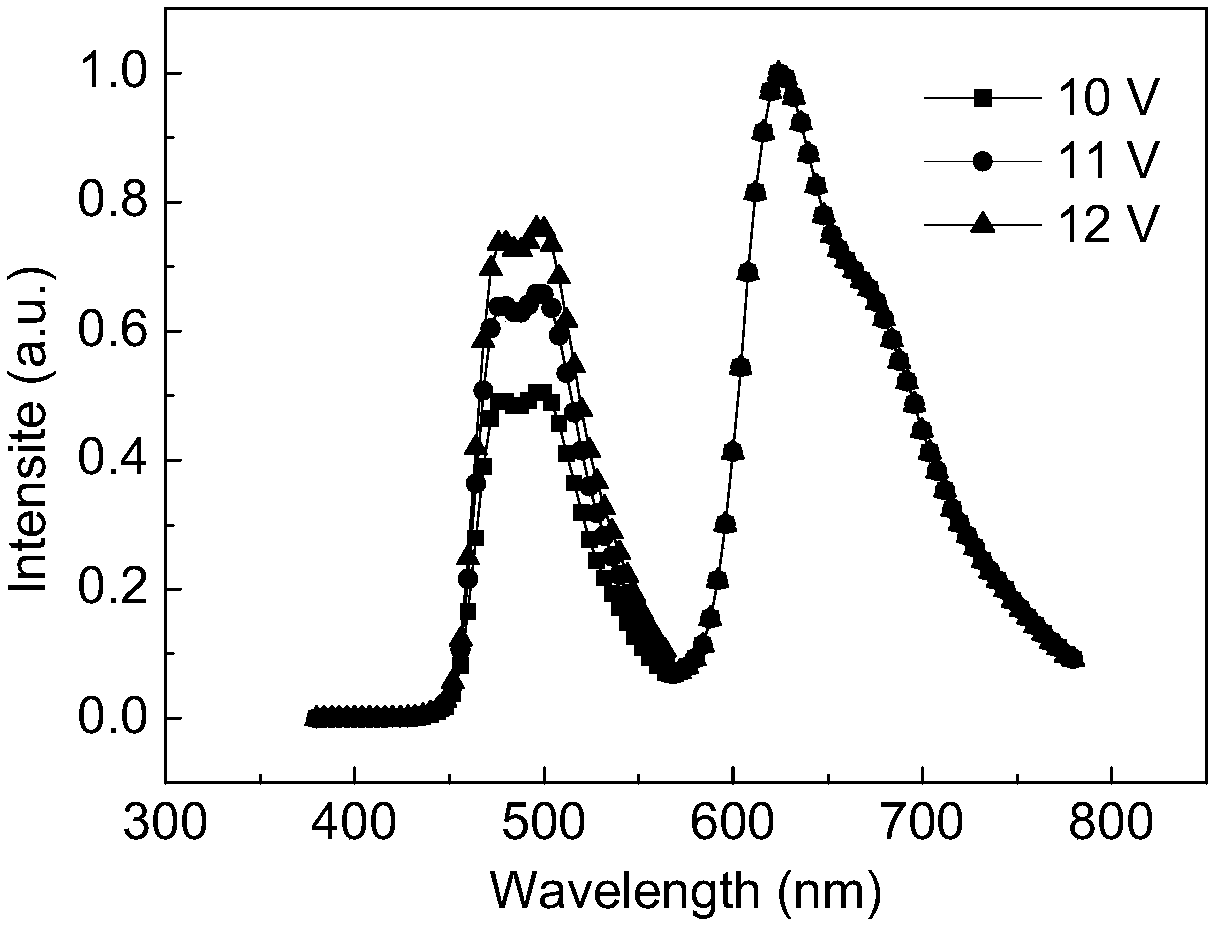

[0047] During the test, the current-voltage-brightness characteristic curve of the d...

Embodiment 1

[0051] Such as figure 1 As shown, the first hole injection layer 2 and the second hole injection layer 9 in the device structure are MoO3 (molybdenum trioxide), and the first hole transport layer 3 and the second hole transport layer 10 are NPB (C44H32N2) , the host material of the first light emitting layer 4 is CBP (C36H24N2), the guest dye is Ir(piq)2(acac)(C35H27N2O2Ir), the first electron transport layer 5 and the second electron transport layer 13 are Bphen(4,7- Biphenyl-1,10-phenanthroline, the first electron injection layer 6 and the second electron injection layer are LiF (lithium fluoride), the electron type intermediate layer 7 is C60 (fullerene), the hole type intermediate layer Layer 8 is CuPc (copper phthalocyanine), the host material of the second light-emitting layer 11 is CBP (C36H24N2), and the guest dye is FIrpic (bis (4,6-difluorophenylpyridine-N, C2) picolinate iridium ), the cathode electrode 14 is aluminum. The whole device structure is described as:

...

Embodiment 2

[0061] Such as figure 1 As shown, the host material of the first light-emitting layer 44 in the device structure is CBP (C36H24N2), and the guest dye is FIrpic (bis (4,6-difluorophenylpyridine-N, C2) picolinate iridium), the first The host material of the second light-emitting layer 1111 is CBP (C36H24N2), and the guest dye is Ir(piq)2(acac)(C35H27N2O2Ir). The entire device structure is described as:

[0062] Glass substrate / ITO / MoO3(3nm) / NPB(30nm) / CBP:10%FIrpic(30nm) / BPhen(40nm) / LiF(1nm) / C60(5nm) / CuPc(5nm) / MoO3(3nm) / NPB(30nm) / CBP:5%Ir(piq)2(acac)(30nm) / BPhen (40nm) / LiF(1nm) / Al(150nm)

[0063] The fabrication process of the device is similar to that of Example 1.

[0064] Device B was produced in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap