Bone repair material having tissue oxygenation function and application of bone repair material

A bone repair and function technology, applied in additive processing, medical science, prosthesis, etc., can solve the problems of lack of oxygen supply, affecting the speed of wound healing, etc., to achieve high safety, increase recovery speed and success rate, speed up the effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

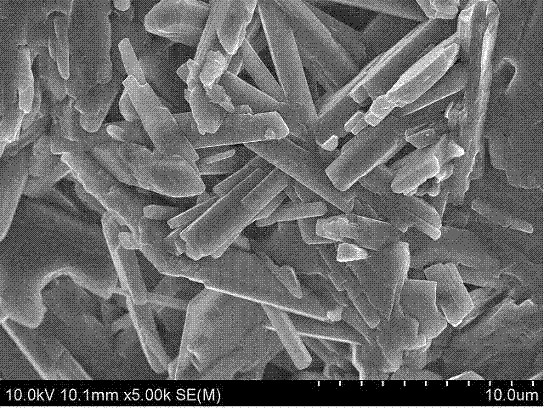

[0031] 1. Preparation of gelatin-modified α-TCP

[0032] (1) Mix calcium hydrogen phosphate and calcium carbonate in a molar ratio of 2:1. The mixing method is ultrapure water, 400rpm ball milling and mixing under the ball milling medium, the mixing time is 2-4h, and the mixed suspension is dried in an oven at 130°C.

[0033] (2) The above-mentioned dried raw materials are calcined in a muffle furnace at 1250-1400°C for 2-4 hours at high temperature, taken out and rapidly cooled in a blast environment to obtain α-TCP powder. The product was ball-milled with absolute ethanol as the ball-milling medium at 450 rpm for 2-4 hours, and the suspension after ball-milling was used to remove ethanol by a rotary evaporator, and dried in an oven at 60°C.

[0034] (3) Prepare an aqueous gelatin solution with a mass fraction of 0.05-0.5%. The preparation method is stirring and dissolving under heating at 50° C., and the stirring method is magnetic stirring or mechanical stirring. Mix the...

Embodiment 2

[0041] 1. Preparation of gelatin-modified α-TCP

[0042] (1) Mix calcium hydrogen phosphate and calcium carbonate in a molar ratio of 2:1. The mixing method is ultrapure water, 400rpm ball milling and mixing under the ball milling medium, the mixing time is 2-4h, and the mixed suspension is dried in an oven at 130°C.

[0043](2) The above-mentioned dried raw materials are calcined in a muffle furnace at 1250-1400°C for 2-4 hours at high temperature, taken out and rapidly cooled in a blast environment to obtain α-TCP powder. The product was ball-milled with absolute ethanol as the ball-milling medium at 450 rpm for 2-4 hours, and the suspension after ball-milling was used to remove ethanol by a rotary evaporator, and dried in an oven at 60°C.

[0044] (3) Prepare an aqueous gelatin solution with a mass fraction of 0.05-0.5%. The preparation method is stirring and dissolving under heating at 50° C., and the stirring method is magnetic stirring or mechanical stirring. Mix the ...

Embodiment 3

[0050] 1. Preparation of gelatin-modified α-TCP

[0051] (1) Mix calcium hydrogen phosphate and calcium carbonate in a molar ratio of 2:1. The mixing method is ultrapure water, 400rpm ball milling and mixing under the ball milling medium, the mixing time is 2-4h, and the mixed suspension is dried in an oven at 130°C.

[0052] (2) The above-mentioned dried raw materials are calcined in a muffle furnace at 1250-1400°C for 2-4 hours at high temperature, taken out and rapidly cooled in a blast environment to obtain α-TCP powder. The product was ball-milled with absolute ethanol as the ball-milling medium at 450 rpm for 2-4 hours, and the suspension after ball-milling was used to remove ethanol by a rotary evaporator, and dried in an oven at 60°C.

[0053] (3) Prepare an aqueous gelatin solution with a mass fraction of 0.05-0.5%. The preparation method is stirring and dissolving under heating at 50° C., and the stirring method is magnetic stirring or mechanical stirring. Mix the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com