Moldfungi suspension culture method by high throughput screening

A technology for suspension culture and filamentous bacteria, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problem of prolonging the breeding process of strains, inconvenient product detection, and detection technology without high-throughput screening To achieve the effect of shortening the process of strain selection, increasing the probability of excellent strains, and facilitating selection and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

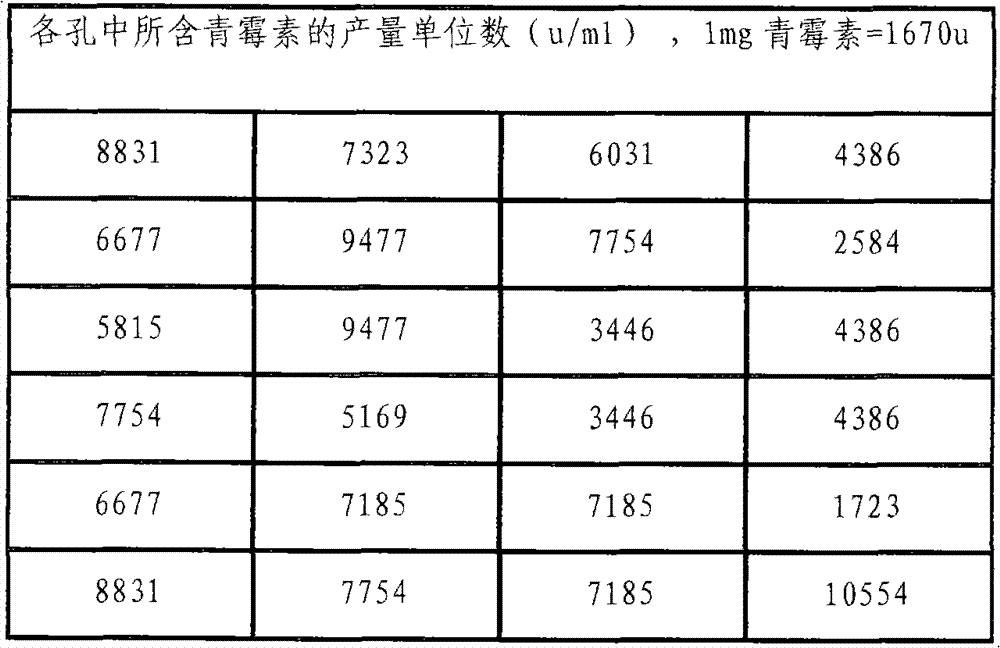

[0029] Take the screening of high-yield strains of penicillin as an example:

[0030] Strain: Penicillium chrysogenum p09

[0031] The main components of solid medium: sucrose, peptone, corn steep liquor, yeast powder, magnesium sulfate, potassium dihydrogen phosphate, agar, pH6.5-7.2

[0032] The main components of the liquid medium: lactose, corn steep liquor, sodium sulfate, ammonium sulfate, magnesium sulfate, potassium dihydrogen phosphate, phenylacetic acid

[0033] Cultivation temperature: 25-30°C

[0034] Multi-well plate: 24-well plate

[0035] (1) Mycelia or spores: A large number of mycelia or spores of Penicillium chrysogenum that may have genetic differences were obtained.

[0036] (2) Colony formation: Mycelia or spores are appropriately diluted, spread on a solid medium, and spores germinate at 25-30°C to form colonies, and the culture time is 3-5 days.

[0037](3) Add culture fluid (liquid medium) in 24 well plate, culture fluid is about 1 / 3-2 / 3 of pore vol...

Embodiment 2

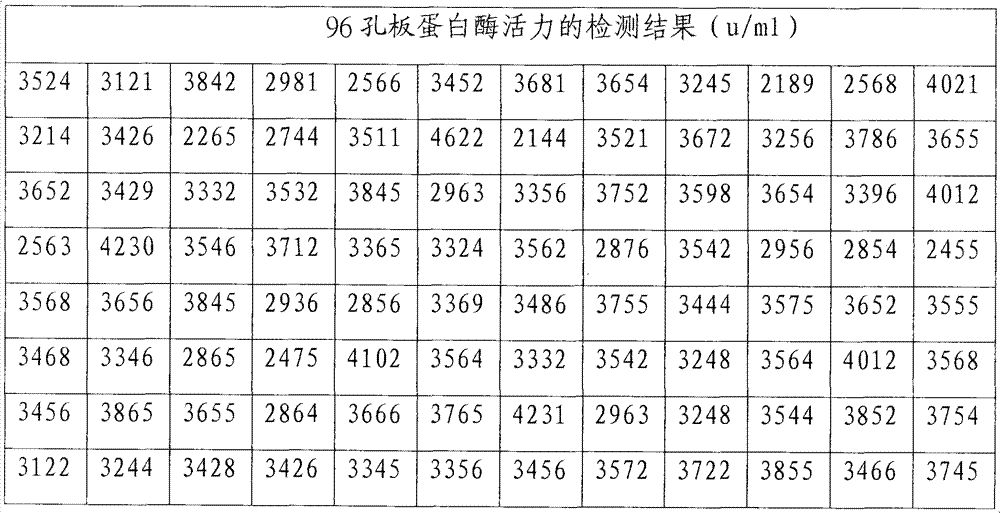

[0043] Screening of High Protease Producing Strains

[0044] Strain: Aspergillus oryzae 3042

[0045] Plate solid medium: boil 200g potatoes for 30min to extract juice, 20g sucrose, 1g potassium dihydrogen phosphate, 0.5g magnesium sulfate, 18g agar, 1000ml water, pH 6.2

[0046] Liquid medium: 100g bran extract juice, 10g soybean powder, 1g potassium dihydrogen phosphate, 0.5 magnesium sulfate, 900ml water, pH 6.2

[0047] Culture temperature: 28-32°C

[0048] Multi-well plate: 24-well plate

[0049] (1) Hyphae or spores: obtain a large number of hyphae or spores that Aspergillus oryzae may have genetic differences.

[0050] (3) Bacterial colony formation: On a flat solid medium, spores germinate at 28-30° C. to form colonies, and the culture time is 1-2 days. (The enzyme production time of this bacterium is early, so the culture time on solid medium should not be too long)

[0051] (3) Add culture medium (i.e. liquid medium) to the 24-well plate, and the culture medium ...

Embodiment 3

[0056] This embodiment still takes the screening of high protease-producing strains as an example. The difference from Example 2 is that in (4), 0.5% agar is added to the liquid medium to suspend the colonies in the liquid medium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com