A kind of preparation method and application of visible light catalyst

A catalyst and visible light technology, applied in chemical instruments and methods, botanical equipment and methods, physical/chemical process catalysts, etc., can solve the problems of limited photocatalytic activity and low light utilization efficiency, and achieve good catalytic effect and good sterilization Effect, the effect of improving the ability to absorb visible light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) g-C 3 N 4 preparation of

[0028] Weigh a certain amount of urea into a porcelain boat, and use a porcelain boat of the same size to buckle it upside down, so that the urea is in a relatively sealed environment. Then the porcelain boat was placed in a tube furnace, and the temperature was raised to 550°C at a rate of 5°C / min under the protection of nitrogen, and calcined for 4h. Finally, it was naturally cooled to room temperature to obtain a light yellow solid, which was then ground in an agate mortar to obtain g-C3N4 powder.

[0029] (2) Au / Ag / g-C 3 N 4 preparation of

[0030] Measure 0.157mL of silver nitrate (AgNO 3 ) and 0.836mL of chloroauric acid (HAuCl 4 ) solution together into the beaker, then measure 5ml of polyvinyl alcohol (PVA) solution into the beaker, and magnetically stir at room temperature to obtain a uniform solution. Then weigh the g-C prepared in 2g step (1) 3 N 4 Powder was added to the solution and stirring was continued for 1 hour....

Embodiment 2

[0034] With embodiment 1, only change the volume of the silver nitrate solution measured in embodiment 1 step (2) to be 0.079mL, 0.314mL; The volume of corresponding chloroauric acid solution is 0.418mL, 1.672mL. That is, the prepared Au / Ag / g-C 3 N 4 Ag and g-C in powder 3 N 4 The mass fraction is 0.25wt.% and 1wt.%; the corresponding Au and g-C 3 N 4 The mass fractions are 1wt.% and 4wt.%. The bactericidal efficiency of the prepared catalysts is shown in Table 1. The results showed that the greater the loading of Ag and Au nanoparticles, the better the efficiency of visible light catalytic sterilization.

[0035] Table 1 The effect of different loadings of noble metal nanoparticles on the catalytic sterilization efficiency of the obtained visible light catalyst

[0036] Noble metal loading (Ag, Au, wt.%) Bactericidal efficiency (%) 0.25,1 70 0.5,2 85 1,4 92

Embodiment 3

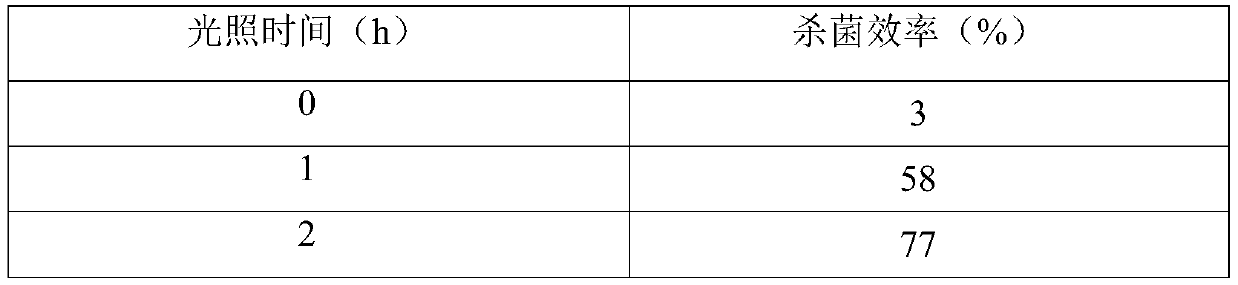

[0038] Same as Example 1, only the amount of catalyst used in step (3) of Example 1 is changed to 0, 50, 100 μg, that is, the final catalyst concentration is 0, 10, 20 μg / mL. The resulting bactericidal efficiencies are shown in Table 2. The results showed that with the increase of the amount of catalyst used, the efficiency of its visible light catalytic sterilization also increased. This is because the amount of catalyst increases, and more ROS are released after light exposure, so it is easier to kill bacteria.

[0039] Table 2 Effect of different catalyst concentrations on visible light catalytic sterilization efficiency

[0040] Catalyst concentration (μg / mL) Bactericidal efficiency (%) 0 5 10 62 20 73 40 85

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com