Zinc selenide ultrathin nanoribbon and anion exchange method for preparing same

A nanobelt and zinc selenide technology, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of reducing application potential, low sunlight utilization rate, utilization, etc., achieving huge application potential and application value, The effect of excellent photohydrogen production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] In another embodiment of the preparation of zinc selenide ultrathin nanobelts of the present invention, the molar content of the ultrathin zinc sulfide / diethylenetriamine hybrid nanobelts used in the first step is 0.1-0.3mmol, water The volume is 10-15ml.

[0074] In another embodiment of preparing zinc selenide ultrathin nanobelts of the present invention, the molar content of sodium selenite in the second step is 1.75-3 times that of ultrathin zinc selenide / diethylenetriamine hybrid nanobelts , 85% hydrazine hydrate is added in a volume of 3-10ml.

[0075] 2) The second aspect of the present invention is to provide a zinc selenide / molybdenum disulfide heterogeneous nanobelt and a preparation method thereof.

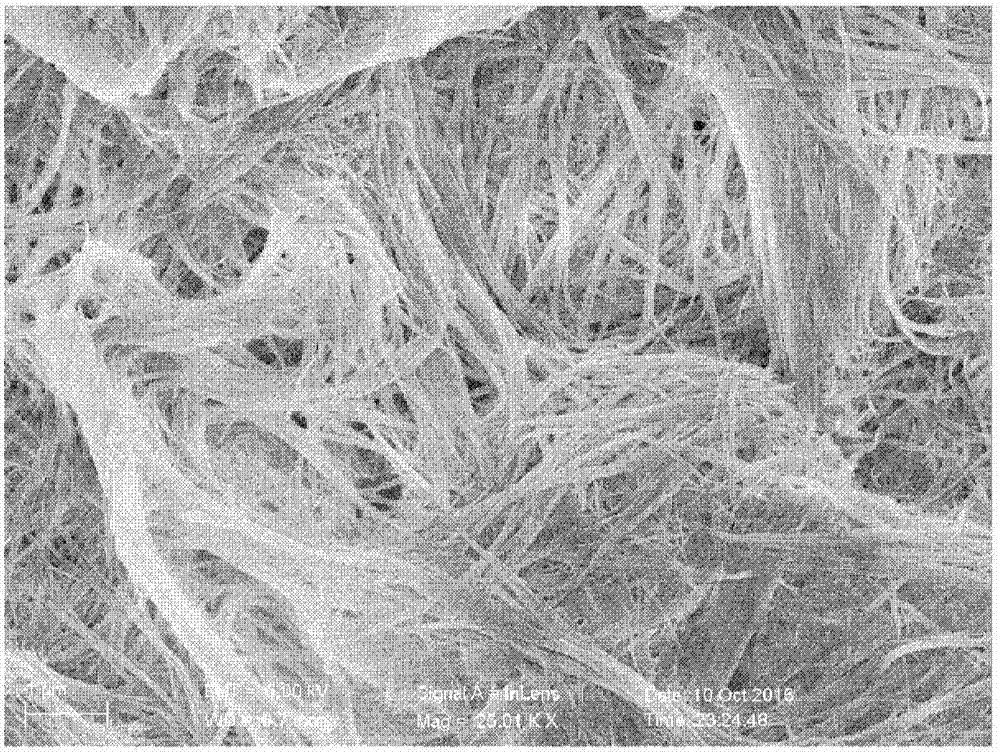

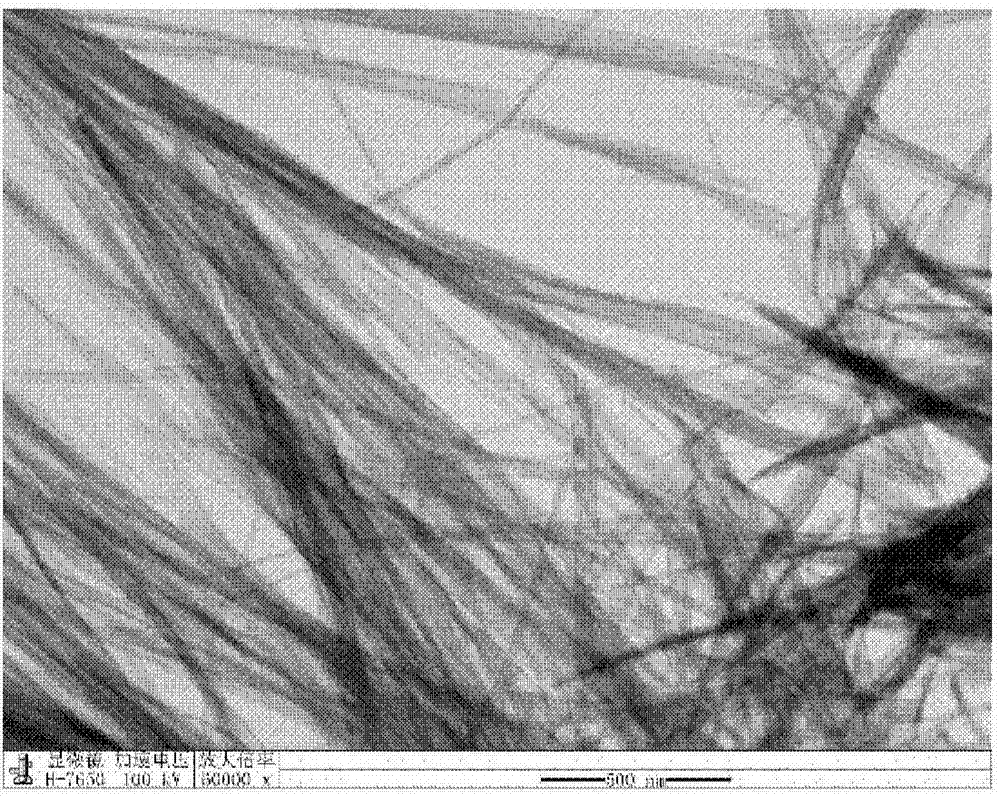

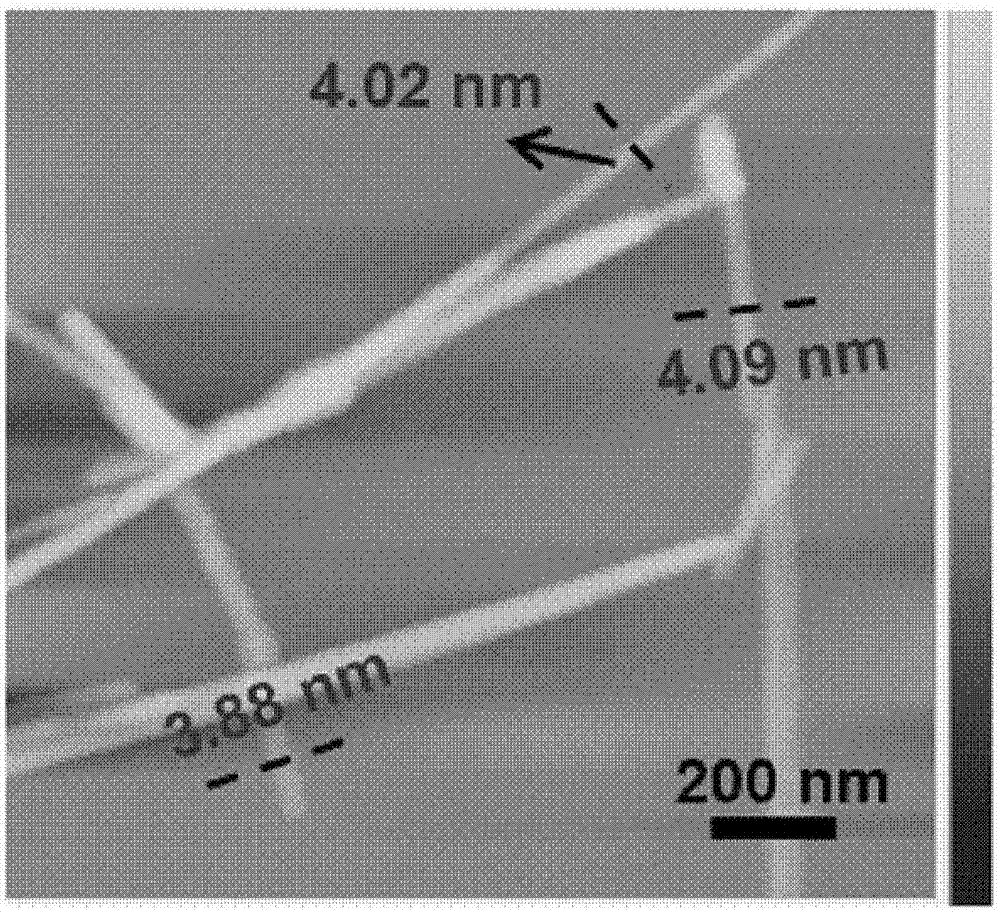

[0076] The zinc selenide / molybdenum disulfide heterogeneous nanoribbon of the present invention presents a nanoribbon structure with a length of 5-10 μm and a width of 17-19 nm, and the surface of the ultrathin nanoribbon has an obvious pore structure, and in M...

Embodiment 1

[0091] Preparation of ZnS / Diethylenetriamine Hybrid Nanobelts

[0092] Add 1mmol of Zn(NO 3 ) 2 ·6H 2 O, and add 75ml of fresh, dry diethylenetriamine, vigorously stir and sonicate to dissolve the zinc salt; then add 1mmol of thiourea to the mixed solution and sonicate and stir to dissolve it; transfer the resulting dispersion to 125ml A single-necked flask connected to a 35cm air condenser, heated in an oil bath at 220°C for 3h, then cooled to room temperature naturally; further filtered and washed with filter paper and freeze-dried at about -70°C to obtain zinc sulfide / diethylenetriamine Hybrid ultrathin nanoribbons.

[0093] Preparation of Porous ZnSe Ultrathin Nanobelts

[0094] Weigh 19.5mg of ultra-thin zinc sulfide / diethylenetriamine hybrid nanoribbon, add it to a 50ml centrifuge tube, add 15ml of deionized water, ultrasonically shake until completely dissolved, then add 69.2mg of sodium selenite to the mixture and 5ml of hydrazine hydrate, sonicate and vibrate unt...

Embodiment 2

[0096] The difference between this embodiment and the specific example 1 is that the mass of the ultra-thin zinc sulfide / diethylenetriamine hybrid nanobelt is changed to 26mg, then the volume of deionized water is added to 10ml, hydrazine hydrate is 8ml, and the reaction temperature is changed to 185 ℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com