Nuclear-shell alloy quantum dots and preparation method thereof

A technology of quantum dots and alloys, which is applied in the field of core-shell alloy quantum dots and its preparation, can solve the problems of cumbersome operation, affecting quantum yield and stability, and limiting the application research of quantum dots to carry out large-scale production of products, etc., to achieve operational Simple, improve quantum yield and stability, reduce the effect of defect generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing a core-shell alloy quantum dot, comprising the following steps:

[0031] (1) Mixing the source of nucleating cations, the source of nucleating anions and a hydrocarbon organic solvent, keeping warm at the nucleation temperature to obtain the quantum dot nuclei; the nucleation temperature is 220-280°C;

[0032] (2) mix the quantum dot core body that described step (1) obtains with shell-forming cation source, shell-forming anion source and hydrocarbon organic solvent at the shell-forming temperature, carry out shell-forming reaction, obtain core-shell alloy quantum dot; The shell forming temperature is 300-318°C;

[0033] The source of nucleating cations and the source of shell-forming cations are independently a source of zinc and / or a source of cadmium;

[0034] The source of nucleating anions and the source of nucleating anions are independently a source of sulfur and / or a source of selenium.

[0035] In the present inve...

Embodiment 1

[0063] Mix 0.16g of Se powder and 20mL of octadecene into a 50mL three-neck flask, heat at 220°C to obtain a light yellow solution, which is used as a Se precursor for later use; dissolve 9mmol (5.643g) of zinc oleate in 30mL of liquid paraffin, Standby as Zn precursor;

[0064] Take 2mL of Se precursor and 8mL of liquid paraffin and mix them into a 100mL three-necked bottle. When heated to 280°C under nitrogen protection, inject 1.3mL of Zn precursor into the above mixed solution, and react at 280°C for 10 minutes to obtain ZnSe Quantum dot nuclei.

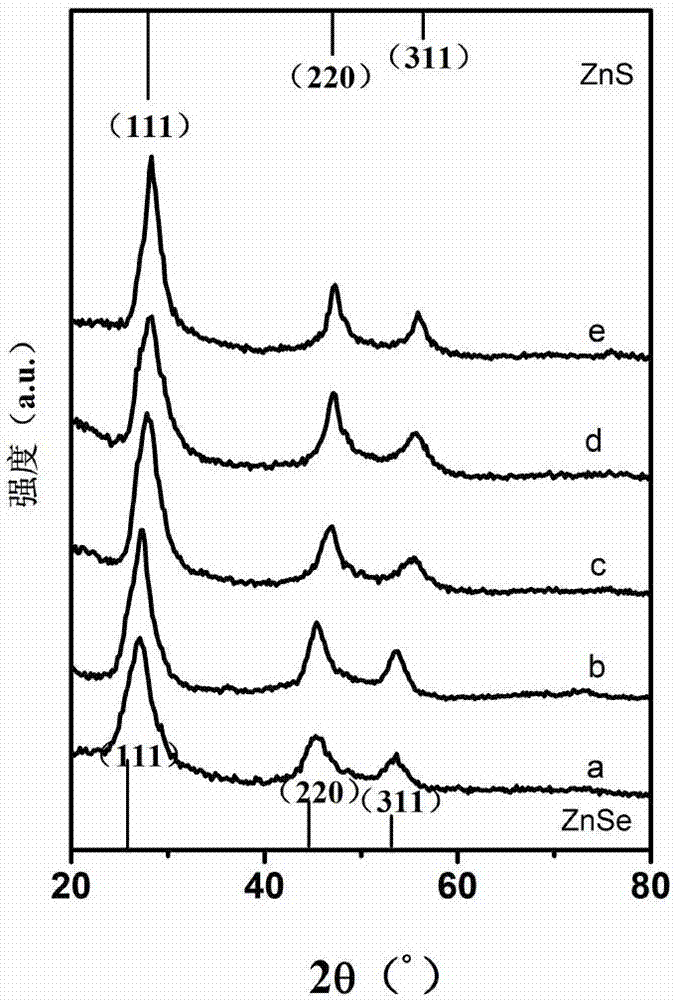

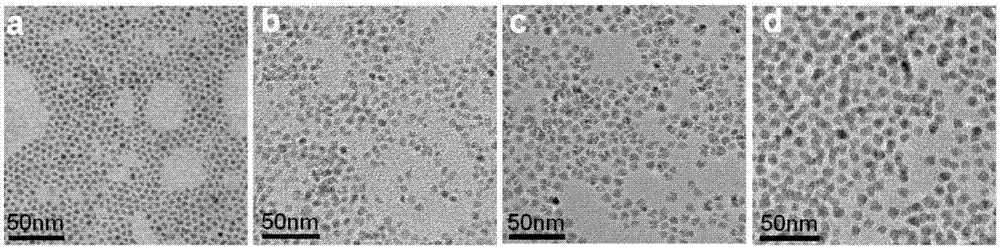

[0065] After the solution after the above reaction for 10 minutes was heated to 318°C, the mixture of 2mL of octane mercaptan and 20mL of Zn precursor was added dropwise to the solution at 318°C obtained above, and the dropping rate was 6mL / h. After the dropwise addition was completed, the temperature was continued to rise and the temperature was kept at 340° C. for 4 hours to grow the shell layer to obtain ZnSe / ZnS core-shell q...

Embodiment 2

[0072] Dissolve 7.294g of cadmium oleate in 30mL of liquid paraffin at 100°C, and use it as a nucleating cation source Cd precursor for later use;

[0073] Take 1mmol Se powder and 20mL liquid paraffin, mix them into a 100mL three-neck flask, raise the temperature to 240°C, inject 5mL of Cd precursor, and react at 240°C for 30min to obtain CdSe quantum dot cores.

[0074] After heating up to 310°C, add dropwise 10mL of a mixture of Cd precursor obtained by dissolving 1.351g of cadmium oleate in 10mL of liquid paraffin and 0.5mL of dodecyl mercaptan, at a rate of 10mL / h. Reaction 4h. Finally, CdSe / CdS core-shell quantum dots are obtained.

[0075] The quantum yield test was carried out on the prepared CdSe / CdS core-shell quantum dots, and the quantum yield was 90%.

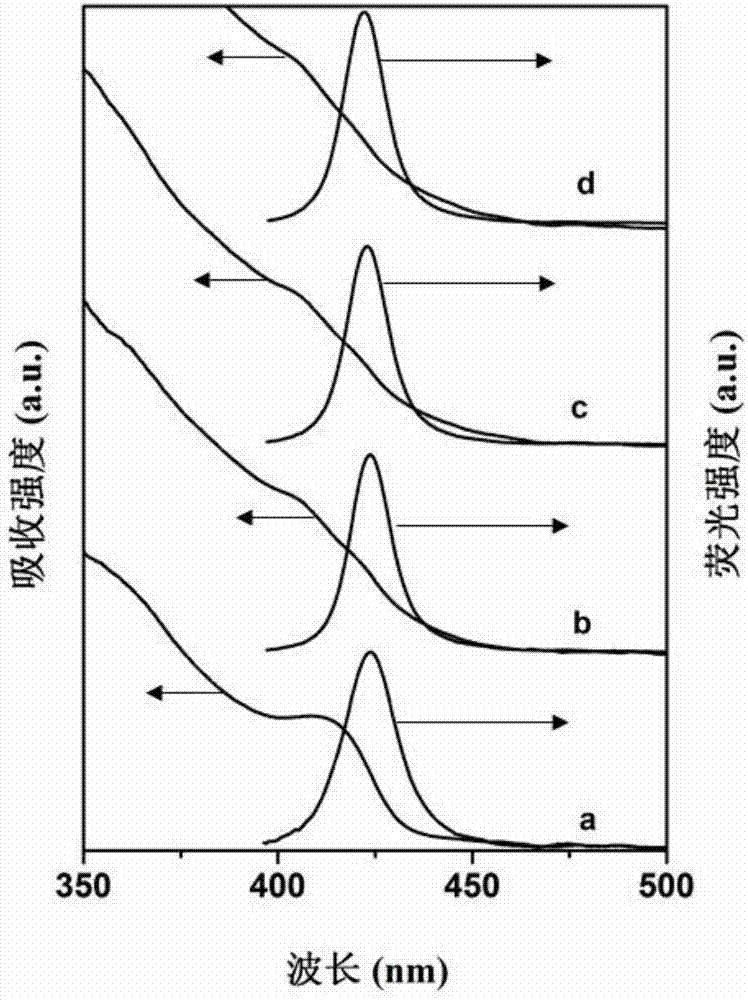

[0076] Fluorescence tests were performed on the quantum nuclei with different growth times and the inner-shell quantum dots with different growth times. The fluorescence spectrum changes are shown in Figure 5 A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com