Production process for aluminum alloy sectional material used for manufacturing of fishing tool

An aluminum alloy profile and production process technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems affecting the quality of fishing gear and its parts, affecting the normal use of fishing gear and its parts, etc., to achieve stable quality and increase flow performance, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

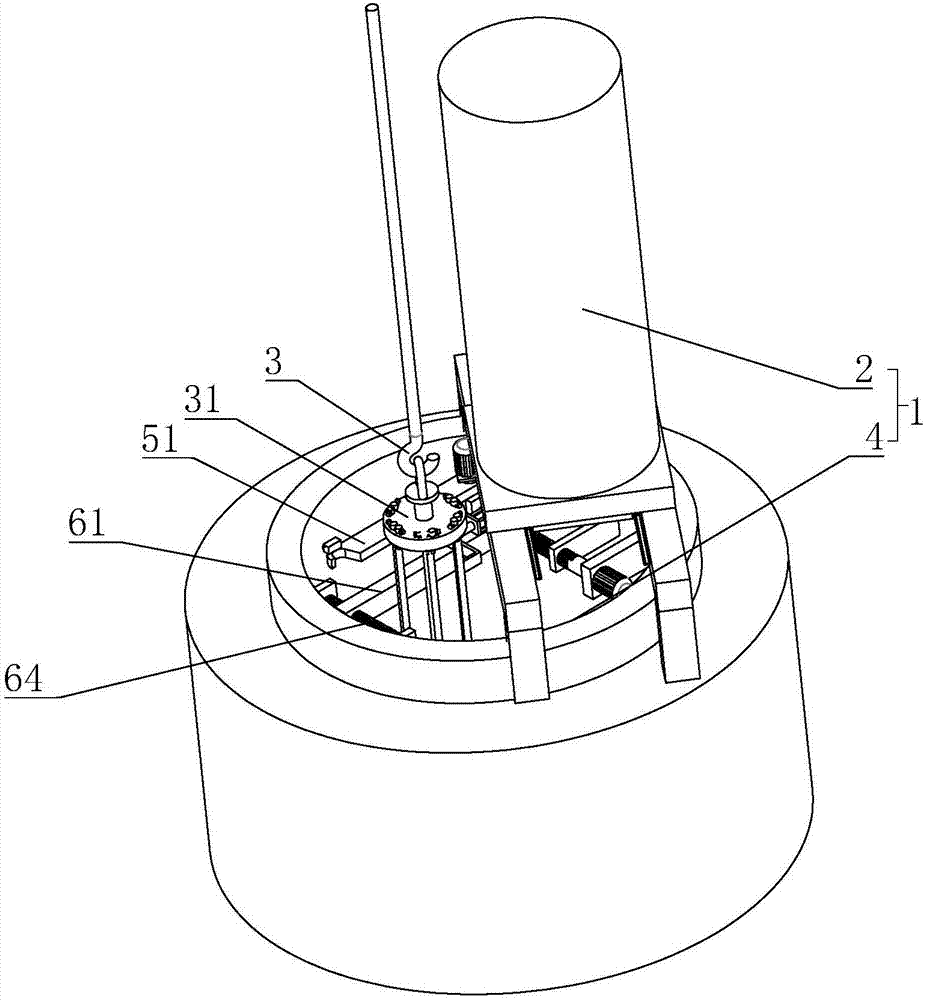

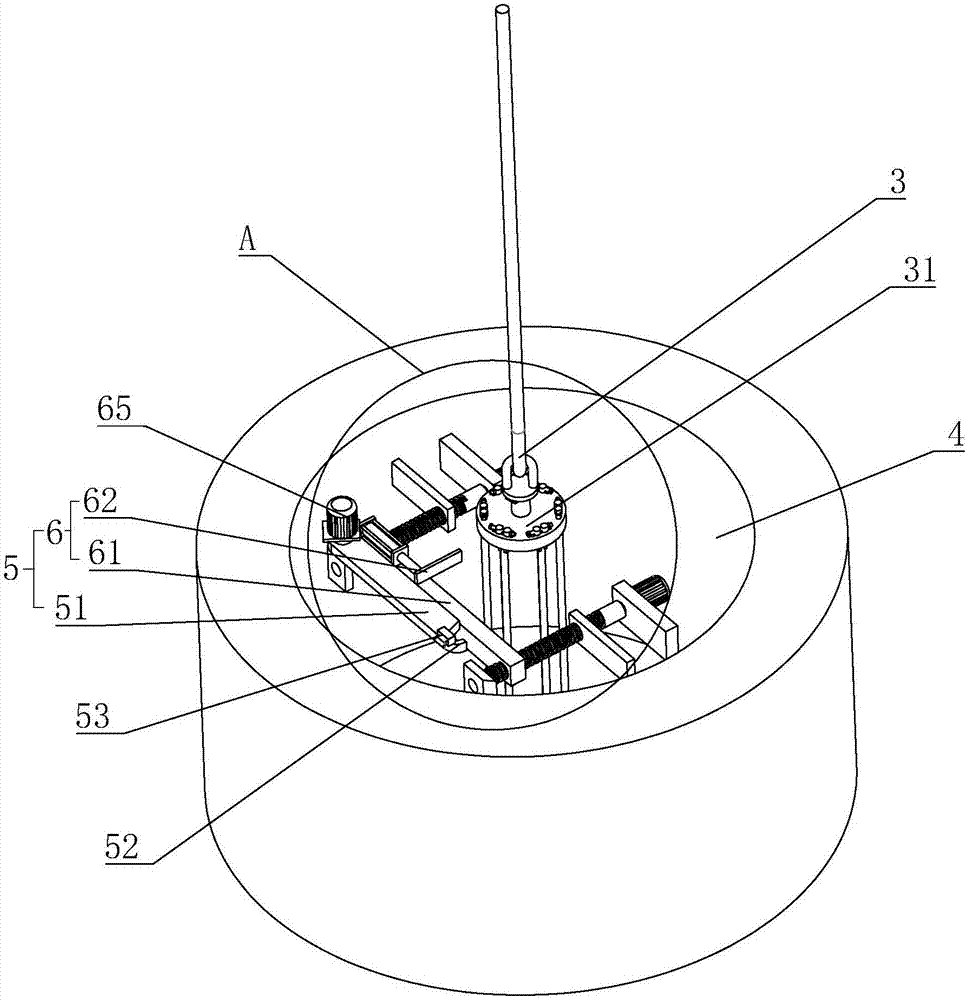

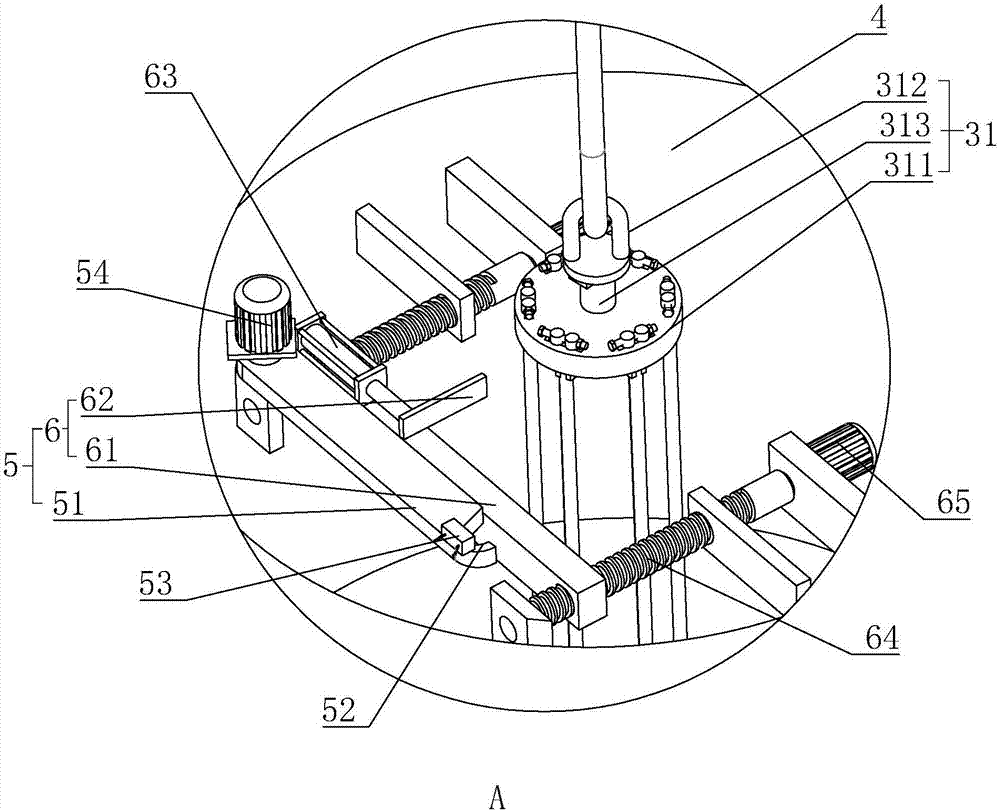

Image

Examples

Embodiment 1

[0038] Embodiment 1: a kind of production process for the aluminum alloy profile of fishing gear, comprises the following steps:

[0039]①Smelting the raw materials, the ingredients and mass fractions contained in the raw materials are: Si 0.45-0.55%, Fe less than 0.20%, Cu 0.15-0.20%, Mn less than 0.05%, Mg 0.45-0.62%, Cr less than 0.02% , Ni less than 0.03%, Zn less than 0.03%, Ti less than 0.03%, Sr 0.02% ~ 0.06%, Sc 0.1% ~ 0.5%, Zr 0.06% ~ 0.3%, impurities less than 0.03%, the balance is aluminum, except magnesium Raw materials other than copper and copper are put into the melting furnace, copper is added after melting, and the charge in the furnace is completely melted and reaches 720-730°C, magnesium ingots are added, fully stirred to melt all the charge, and refining is carried out. Spray the slagging agent evenly into the molten liquid with nitrogen, add 0.5-1 kg of slagging agent per ton of raw materials, and remove the slag; add magnesium ingots, stir fully to melt a...

Embodiment 2

[0047] Example 2: The difference from Example 1 is that in step ①, the ingredients and their mass fractions contained in the raw materials are: Si 0.45-0.55%, Fe less than 0.20%, Cu 0.15-0.20%, Mn less than 0.05%, Mg 0.45~0.62%, Cr less than 0.02%, Ni less than 0.03%, Zn less than 0.03%, Ti less than 0.03%, Sr 0.02%~0.03%, Sc 0.1%~0.3%, Zr 0.06%~0.2%, impurities less than 0.03% %, the balance is aluminum.

Embodiment 3

[0048] Example 3: The difference from Example 1 is that in step ①, the ingredients and mass fractions contained in the raw materials are: Si 0.45-0.55%, Fe less than 0.20%, Cu 0.15-0.20%, Mn less than 0.05%, Mg 0.45~0.62%, Cr less than 0.02%, Ni less than 0.03%, Zn less than 0.03%, Ti less than 0.03%, Sr 0.03%~0.06%, Sc 0.3%~0.5%, Zr 0.2%~0.3%, impurities less than 0.03% %, the balance is aluminum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com