Preparation method and application of mesoporous hydroxyl-ferric oxide Cr (VI) adsorbent

A mesoporous hydroxyl and iron oxide technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of low utilization rate of raw materials, difficult reaction conditions, cumbersome process, etc., and achieve fast adsorption rate. , the effect of cheap and easy-to-obtain raw materials and low process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

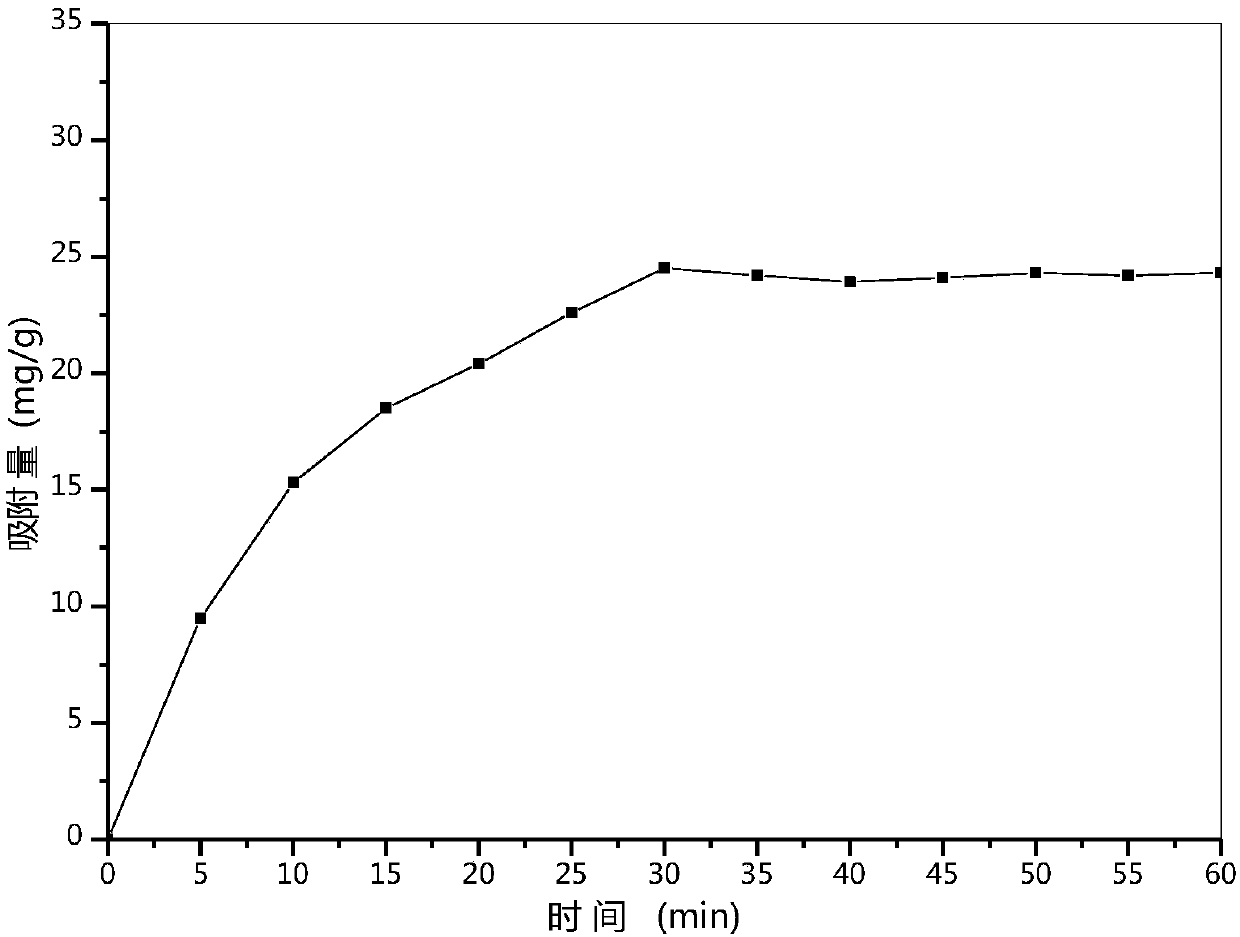

Embodiment 1

[0026] In this embodiment, a method for preparing a mesoporous iron oxyhydroxide Cr(VI) adsorbent comprises the following steps:

[0027] a. Weigh 10.00g of Fe(NO 3 ) 3 , 5.00g of formamide, and 1.00g of P123, mixed in a beaker, then added 20ml of pure water, ultrasonically dissolved for more than 10min, so that Fe(NO 3 ) 3 , formamide and P123 were mixed and dissolved in pure water, and then transferred to a 100ml volumetric flask to obtain a mixed solution of 100ml;

[0028] b. Transfer the mixed solution prepared in the step a to a polytetrafluoroethylene hydrothermal kettle and seal it, place it in a heating box, and conduct a hydrothermal reaction at 150° C. for 5 hours, and generate a precipitated product in the reaction solution;

[0029] c. cooling the reaction solution obtained after the reaction in step b to room temperature, using a Buchner funnel to filter the reaction solution, retaining the precipitated product, and washing the precipitated product twice with ...

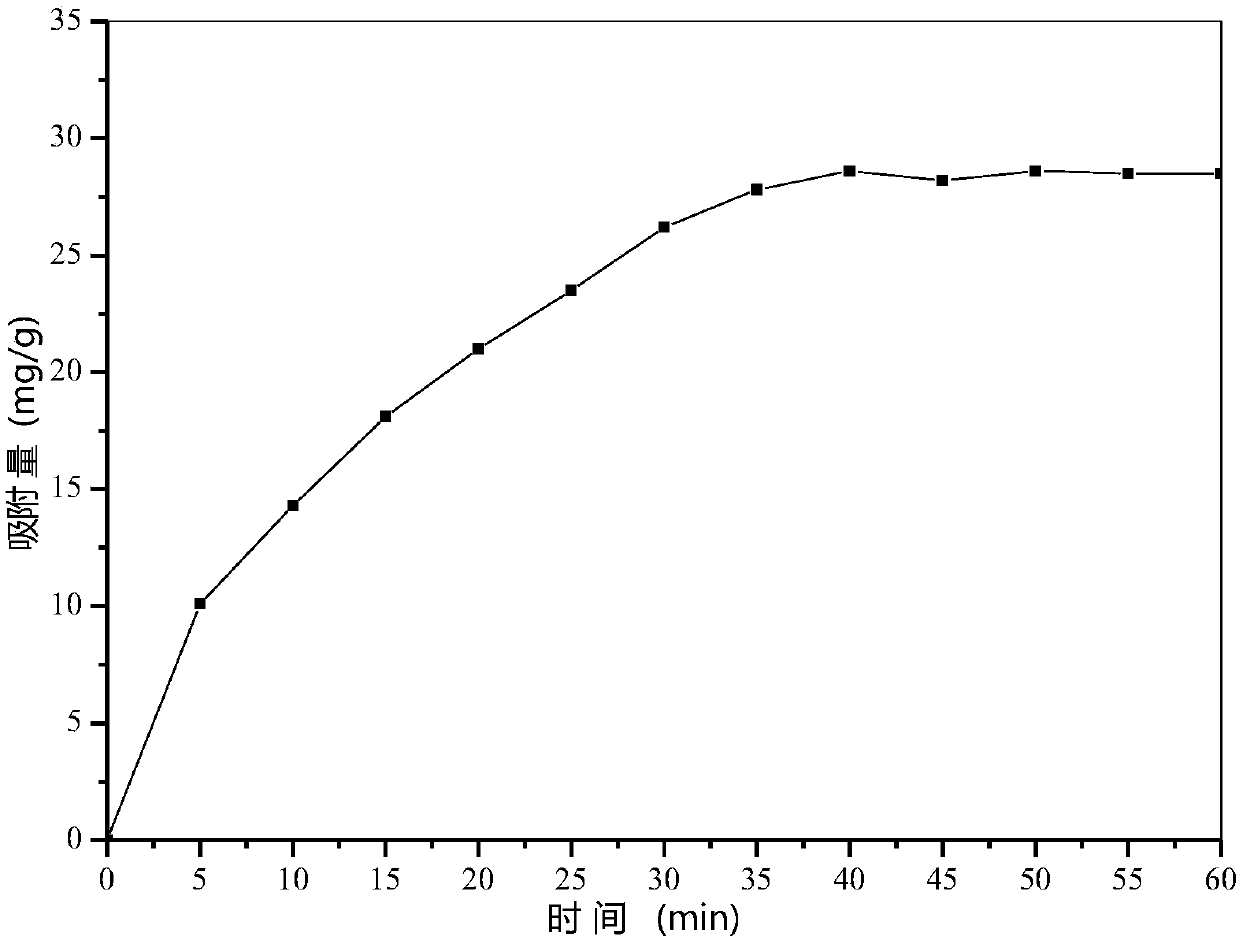

Embodiment 2

[0034] This embodiment is basically the same as Embodiment 1, especially in that:

[0035] In this embodiment, a method for preparing a mesoporous iron oxyhydroxide Cr(VI) adsorbent comprises the following steps:

[0036] a. Weigh 10.00g of Fe with an analytical balance 2 (SO 4 ) 3 , 2.00g of acetamide, and 5.00g of F127, mixed in a beaker, then added 20ml of pure water, ultrasonically dissolved for more than 10min, so that Fe 2 (SO 4 ) 3 , acetamide and F127 were mixed and dissolved in pure water, and then transferred to a 100ml volumetric flask to obtain a mixed solution of 100ml;

[0037] b. Transfer the mixed solution prepared in the step a to a polytetrafluoroethylene hydrothermal kettle and seal it, place it in a heating box, and conduct a hydrothermal reaction at 200° C. for 5 hours, and generate a precipitated product in the reaction solution;

[0038] c. cooling the reaction solution obtained after the reaction in step b to room temperature, using a Buchner funn...

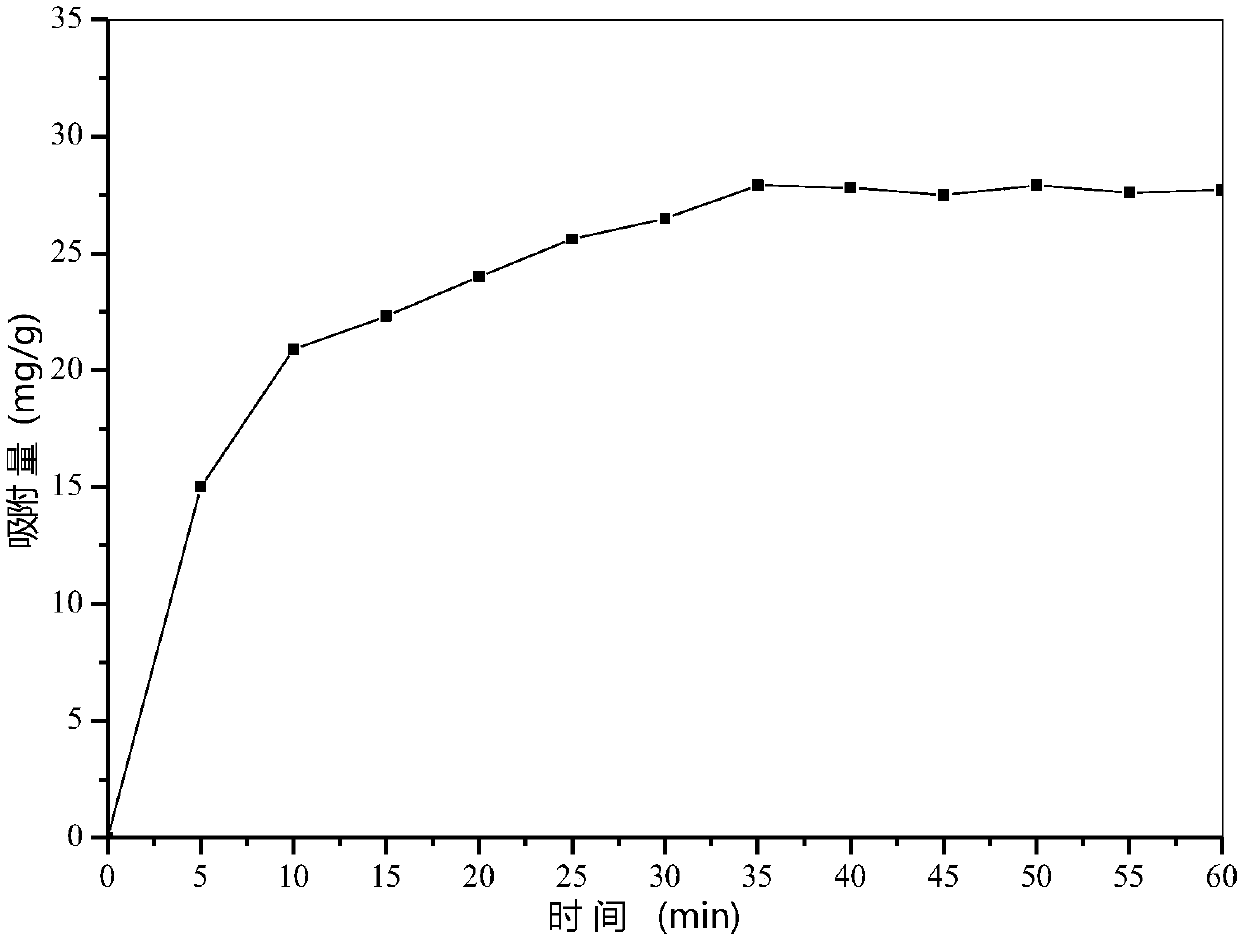

Embodiment 3

[0043] This embodiment is basically the same as the previous embodiment, and the special features are:

[0044] In this embodiment, a method for preparing a mesoporous iron oxyhydroxide Cr(VI) adsorbent comprises the following steps:

[0045] a. Weigh 10.00g of FeCl with an analytical balance 3 , 2.00g of urea, and 5.00g of F108, mixed in a beaker, then added 20ml of pure water, ultrasonically dissolved for more than 10min, so that FeCl 3 , urea and F108 were mixed and dissolved in pure water, and then transferred to a 100ml volumetric flask to obtain a mixed solution of 100ml;

[0046] b. Transfer the mixed solution prepared in the step a to a polytetrafluoroethylene hydrothermal kettle and seal it, place it in a heating box, and conduct a hydrothermal reaction at 200° C. for 5 hours, and generate a precipitated product in the reaction solution;

[0047] c. cooling the reaction solution obtained after the reaction in step b to room temperature, using a Buchner funnel to fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com