Aromatization method

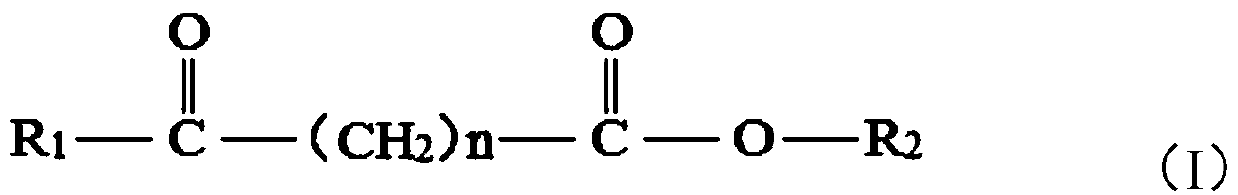

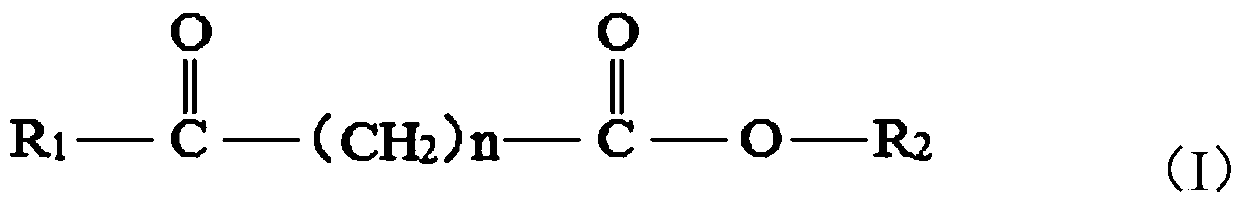

An aromatization and structural formula technology, applied in the field of aromatization, can solve problems such as the inevitable generation of olefin species and catalyst deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

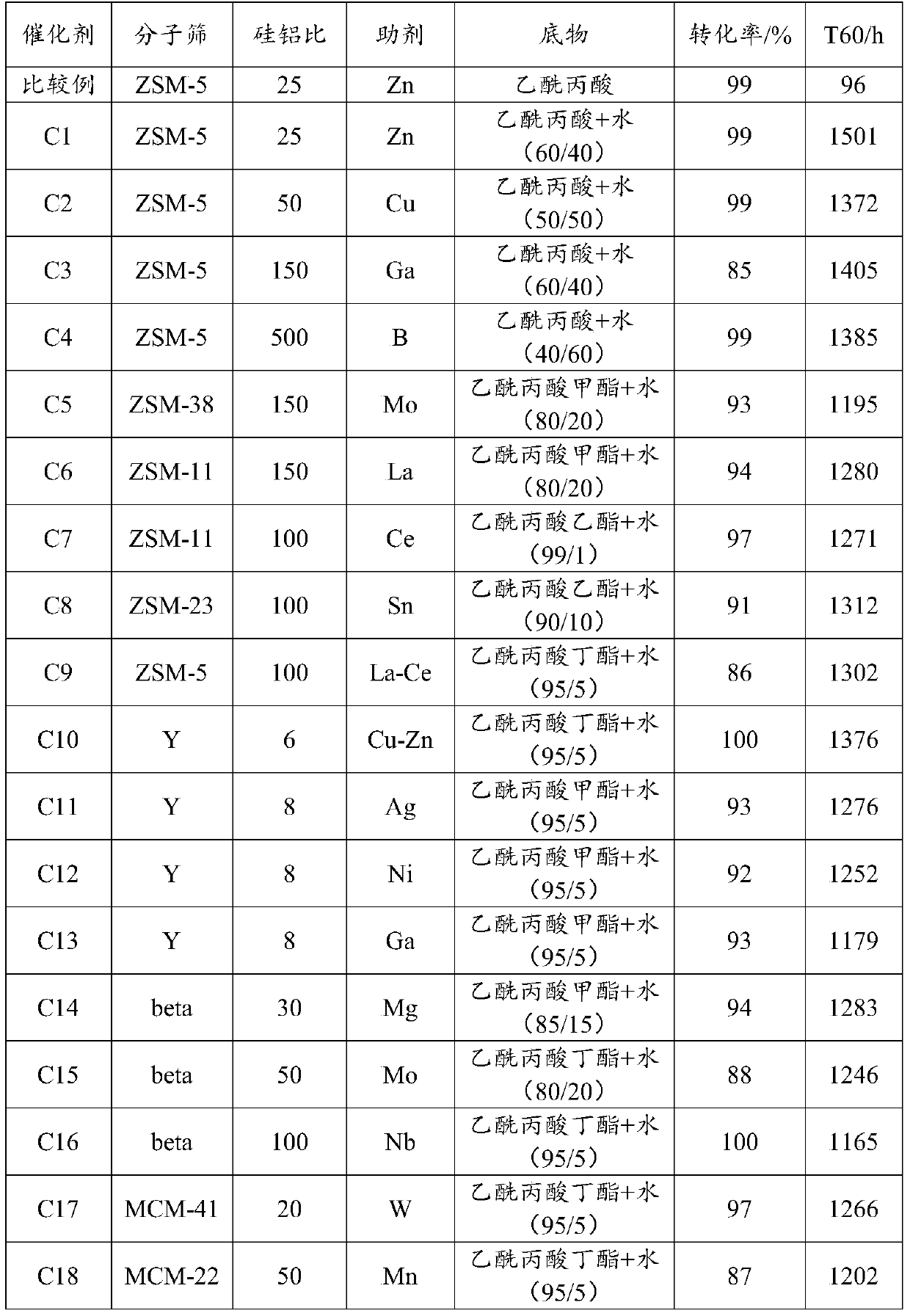

Examples

Embodiment 1

[0049] Weigh 35 grams of ZSM-5 with a silicon-to-aluminum ratio of 25 and 35 grams of γ-alumina, add 2.7 grams of sesame powder, and mix well. Then, 48 grams of nitric acid aqueous solution with a mass percentage of nitric acid of 5.5% was added, kneaded and formed, and extruded. The obtained catalyst precursor was dried at 120°C for 8 hours, calcined at 500°C for 2 hours, and impregnated with Zn(NO 3 ) 2 The Zn addition amount is 1%, and the molecular sieve catalyst is obtained by roasting after drying.

[0050] Weigh 60 grams of corn stalks, place them in an autoclave and add 700 grams of water, then add a 5mol / L sulfuric acid solution with 7% water mass, heat up to 200°C and react for 45 minutes, and then cool down. The cooled reaction solution Filter to obtain a filter cake and a filtrate. The filtrate is a cellulose hydrolysate. After the reaction, mass spectrometry is used to identify the main product of the reaction result as levulinic acid, and the amount produced is 24 g...

Embodiment 2

[0053] Weigh 35 grams of ZSM-5 with a silicon-to-aluminum ratio of 50 and 35 grams of pseudo-boehmite, add 2.7 grams of Sesbania powder, and mix well. Then, 48 grams of nitric acid aqueous solution with a mass percentage of nitric acid of 5.5% was added, kneaded and formed, and extruded. The obtained catalyst precursor was dried at 120°C for 8 hours, calcined at 500°C for 2 hours, and impregnated with Cu(NO 3 ) 2 , Cu addition amount is 2%, after drying, calcining to obtain molecular sieve catalyst C2.

[0054] The catalyst activity evaluation was carried out on a fixed bed, the reaction conditions were 3 grams of catalyst mass, the reaction substrate was levulinic acid + water (50 / 50), and the weight space velocity was 1.0 hour. -1 , Hydrogen pressure 1.0MPa, flow rate 50ml min -1 , The temperature is 420℃. After the reaction, the conversion rate of levulinic acid was 99%, and the T60 was 1372 hours.

Embodiment 3

[0056] Weigh 30 grams of wood, place it in an autoclave and add 300 grams of ethanol, and then add a 5mol / L sulfuric acid solution with 7% water mass, heat up to 200°C and react for 30 minutes, then cool, and filter the cooled reaction solution , Obtain filter cake and filtrate, the filtrate is a cellulose hydrolysate. After the reaction, mass spectrometry is used to identify the main product of the reaction result as levulinic acid, and its production amount is 10.5 grams.

[0057] Weigh 35 grams of ZSM-5 with a silicon-to-aluminum ratio of 150 and 35 grams of pseudo-boehmite to mix, add 2.7 grams of Sesbania powder, and mix well. After that, 48 grams of nitric acid aqueous solution with a mass percentage of nitric acid of 5.5% was added, kneaded and shaped, and Ga(NO 3 ) 2 , The added amount of Ga is 1% of molecular sieve mass, extruded. The obtained catalyst precursor was dried at 120°C for 8 hours and calcined at 500°C for 2 hours to obtain a molecular sieve catalyst C3.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com