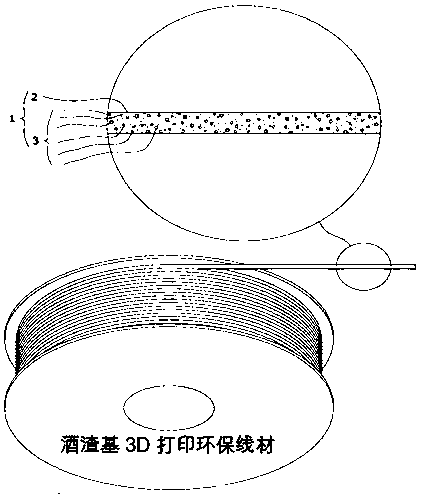

Liquor residue based composite material and technology for preparing wire rods used for 3D printing by using composite material

A 3D printing, wine residue-based technology, applied in the direction of additive processing, etc., can solve the problems of severe global warming, achieve the effects of reducing unpleasant smell, improving efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

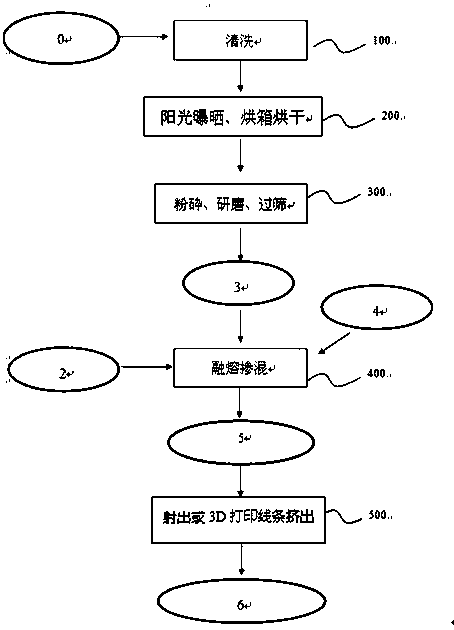

[0040] A preparation method of wine residue-based composite material, comprising the following steps:

[0041] (1) Preparation of distiller's residue recycling raw materials:

[0042] Collect and clean the discarded wine lees after fermentation of Daqu Baijiu in the brewery. After cleaning, expose them to the sun for 10 hours, then dry them in an oven at 185°C for 4 hours, grind them, and sieve them to 105-75 microns (about 150-200 mesh).

[0043] (2) Preparation of wine residue-based composites

[0044] Put the prepared Daqu distiller's residue powder into the extruder with PHA and PBAT in different proportions of 20%, 40%, and 60%, respectively, and add in addition 1wt% compatibilizer (silane coupling agent), 1wt% lubricant (paraffin wax), and 0.4wt% antioxidant (triaryl phosphite), co-extruded with PHA, PBAT composition by twin-screw Blending by machine, the processing temperature is 145-165 ℃, after kneading processing and extrusion, the supercooled water tank is granul...

Embodiment 2

[0050] A preparation method of wine residue-based composite material, comprising the following steps:

[0051] (1) Preparation of distiller's residue recycling raw materials:

[0052] After collecting the discarded distiller's residue after fermentation of Xiaoqu Baijiu in the brewery, clean it, expose it to the sun for 12 hours, then dry it in an oven at 185°C for 4 hours, then crush it, grind it, and sieve it to 20 -25 microns (about 500-625 mesh).

[0053] (2) Preparation of wine residue-based composites

[0054] To investigate the strength of composite materials prepared by adding different proportions of distiller’s residue powder, ABS was first dried in a dehumidification oven for 4 hours, and the temperature of the dehumidification oven was 90°C to make the moisture content less than 0.1%. Afterwards, the ABS plastic composition after drying is added in the extruder, the prepared wine residue powder (20%, 40%, 60%) is mixed with the ABS after dehydration, and addition...

Embodiment 3

[0059] A method for preparing a high-strength biodegradable wine residue-based composite material, comprising the following steps:

[0060] (1) Preparation of distiller's residue raw material:

[0061] After collecting the waste lees from Daqu Baijiu produced in the brewery, clean them, expose them to the sun for 48 hours, then dry them in an oven at 195°C for 10 hours, crush them, grind them, and sieve them to 15- 25 microns (about 500-900 mesh).

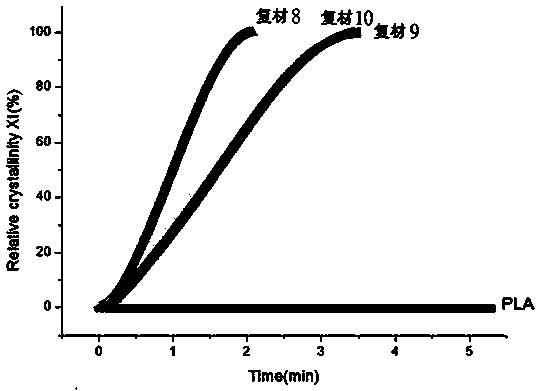

[0062] (2) High-strength biodegradable wine residue-based composites

[0063] Dry the PLA in a dehumidification oven for 4 hours, the temperature of the dehumidification oven is 85°C, and the dew point temperature is -40°C. The prepared wine lees raw material and PLA after dehydration are then mixed with different wine lees ratios (10%, 20%, 40%, 60%), and an additional mass percentage of the substance (PLA and wine lees total mass) is added 1.5 wt% compatibilizer (glycidyl methacrylate), 3% lubricant (plasticizer-adipate), 0.15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com