Anti-bacterial oil-proof paper and preparation method thereof

A technology of oil-proof paper and oil layer, which is applied in the direction of special paper, paper, papermaking, etc., can solve the problems of seersucker paper disease, porosity reduction, and high energy consumption of paper, so as to prevent pollution, reduce additives, and ensure health. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

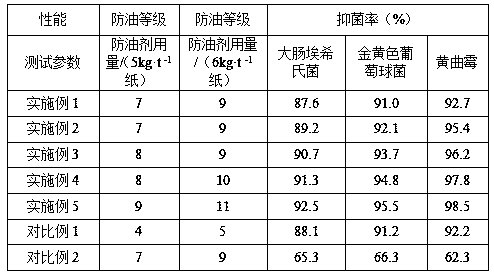

Examples

Embodiment 1

[0017] An antibacterial and oil-proof paper, comprising base paper and an oil-proof layer, the oil-proof layer is prepared from the following ingredients in parts by weight: 5 parts of zein, 1 part of konjac powder, 1 part of artemisia gum, 3 parts of edible polyvinylpyrrolidone, 3 parts of propolis powder, 2 parts of aqueous stearic acid, 2.5 parts of tributyl citrate, 5 parts of triacetin glyceride, 0.5 part of kudzu rice polysaccharide, 0.5 part of porphyrin polysaccharide, 80 parts of water.

[0018] The preparation method of the above antibacterial and oil-proof paper is as follows: (1) Add zein into water, keep the stirring speed at 300r / min, raise the temperature to 95°C and keep stirring until it is completely gelatinized, keep it warm for 60min, and configure it with a mass concentration of 10% Put the gelatinized starch solution in a constant temperature water bath at 65°C to keep warm for later use; (2) Dissolve konjac powder, artemisia gum, edible polyvinylpyrrolido...

Embodiment 2

[0020] An antibacterial and oil-proof paper, comprising a base paper and an oil-proof layer, the oil-proof layer is prepared from the following ingredients in parts by weight: 10 parts of zein, 3 parts of konjac powder, 3 parts of artemisia gum, 1 part of edible polyvinylpyrrolidone, 7 parts of propolis powder, 0.5 parts of aqueous stearic acid, 5 parts of tributyl citrate, 2.5 parts of glycerol triacetate, 2 parts of kudzu rice polysaccharide, 2 parts of porphyrin polysaccharide, 120 parts of water.

[0021] The preparation method of the above antibacterial and oil-proof paper is as follows: (1) Add zein into water, keep the stirring speed at 500r / min, raise the temperature to 95°C and keep stirring until it is completely gelatinized, keep it warm for 40min, and configure it to a mass concentration of 10% Put the gelatinized starch solution in a constant temperature water bath at 65°C to keep warm for later use; (2) Dissolve konjac powder, artemisia gum, edible polyvinylpyrrol...

Embodiment 3

[0023] An antibacterial and oil-proof paper, comprising a base paper and an oil-proof layer, the oil-proof layer is prepared from the following ingredients in parts by weight: 6 parts of zein, 1.5 parts of konjac powder, 1.5 parts of artemisia gum, 2.5 parts of edible polyvinylpyrrolidone, 6 parts of propolis powder, 0.8 parts of aqueous stearic acid, 4 parts of tributyl citrate, 3 parts of glycerol triacetate, 0.8 parts of kudzu rice polysaccharide, 0.8 part of porphyrin polysaccharide, 90 parts of water.

[0024] The preparation method of the above antibacterial and oil-proof paper is as follows: (1) Add zein into water, keep the stirring speed at 350r / min, raise the temperature to 95°C and stir continuously until it is completely gelatinized, keep it warm for 45min, and configure it to a mass concentration of 10% Put the gelatinized starch solution in a constant temperature water bath at 65°C to keep warm for later use; (2) Dissolve konjac powder, artemisia gum, edible polyv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com