A method and system for harmless treatment of lithium-ion batteries

A lithium-ion battery, harmless treatment technology, applied in the field of lithium-ion batteries, can solve the problems that the electrolyte treatment problem has not been effectively solved, the electrolyte cannot be removed, and it is difficult to achieve scale, etc., so as to facilitate large-scale The effect of industrialization development, efficient and harmless treatment, and avoidance of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

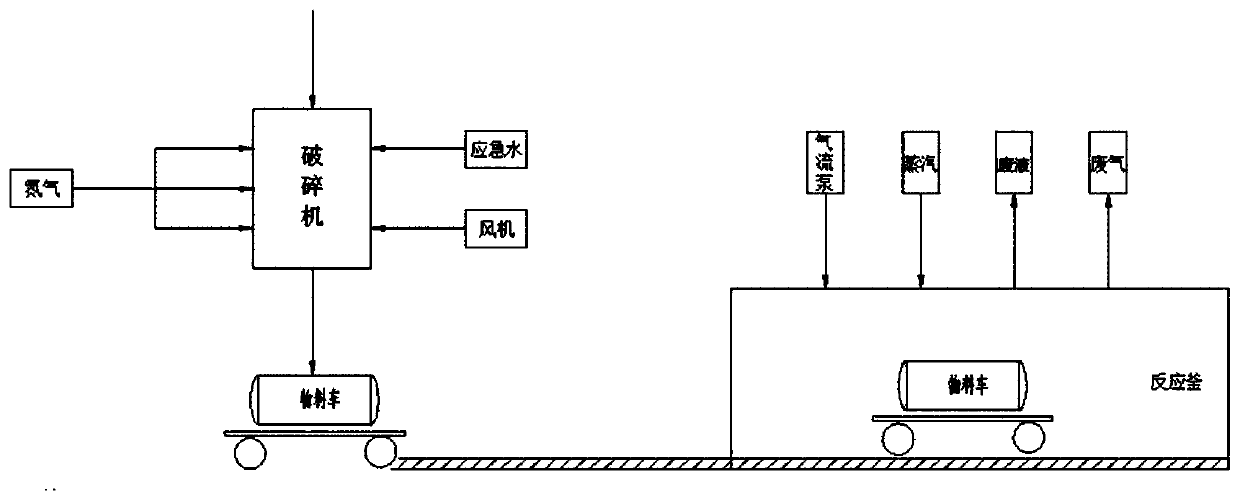

[0040] The harmless treatment method of lithium ion battery of the present invention comprises the following steps:

[0041] 1) Take 1.5 tons of decommissioned lithium iron phosphate batteries and put them into a jaw crusher for crushing. After crushing, a lithium-ion battery crushed material with a particle size of about 0.5cm is obtained; after the crushing is completed, open the discharge port of the crusher, Load the crushed material into three vehicles in turn with a volume of 1m 3 in the material cart;

[0042] 2) Run the three material trucks loaded with crushed lithium-ion battery materials in step 1) into the steam reaction chamber, seal the reaction chamber, evacuate the reaction chamber to make the vacuum degree reach -0.09MPa, and then pour into the reaction chamber Introduce steam at a temperature of 120°C to make the pressure in the reaction chamber reach 0.2MPa, carry out steam reaction for 20min, then evacuate to -0.08MPa, keep for 5min, continue to pass in st...

Embodiment 2

[0056] The harmless treatment method of lithium ion battery of the present invention comprises the following steps:

[0057] 1) Take 4.5 tons of decommissioned ternary material lithium batteries and put them into an impact crusher for crushing. After crushing, a lithium-ion battery crushed material with a particle size of about 4cm is obtained; after the crushing is completed, open the discharge port of the crusher, Load the crushed material into three vehicles with a volume of 3m 3 in the material cart;

[0058] 2) Run the three material trucks loaded with crushed lithium-ion battery materials in step 1) into the steam reaction chamber, seal the reaction chamber, evacuate the reaction chamber to make the vacuum degree reach -0.09MPa, and then pour the steam into the reaction chamber Introduce steam at a temperature of 150°C to make the pressure in the reaction chamber reach 0.48MPa, carry out steam reaction for 20min, then evacuate to -0.08MPa, keep for 5min, continue to pas...

Embodiment 3

[0063] The harmless treatment method of lithium ion battery of the present invention comprises the following steps:

[0064] 1) Take 1.5 tons of decommissioned lithium iron phosphate batteries and put them into a jaw crusher for crushing. After crushing, a lithium-ion battery crushed material with a particle size of 1cm is obtained; after the crushing is completed, open the discharge port of the crusher and crush the The materials are sequentially loaded into three vehicles with a volume of 1m 3 in the material cart;

[0065]2) Run the three material trucks loaded with crushed lithium-ion battery materials in step 1) into the steam reaction chamber, seal the reaction chamber, evacuate the reaction chamber to make the vacuum degree reach -0.09MPa, and then pour into the reaction chamber Introduce steam at a temperature of 135°C to make the pressure in the reaction chamber reach 0.32MPa, carry out steam reaction for 20min, then evacuate to -0.08MPa, keep for 5min, continue to i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com