Recycling method of positive electrode powder of waste lithium ion battery

A lithium-ion battery and positive electrode technology, which is applied in the field of waste lithium battery positive electrode powder recovery, can solve problems such as pollution, low purity of nickel-cobalt-lithium-manganese-oxide ternary materials, and affect the impurity content of lithium-containing solutions, so as to improve the leaching rate , the effect of reducing the amount of acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

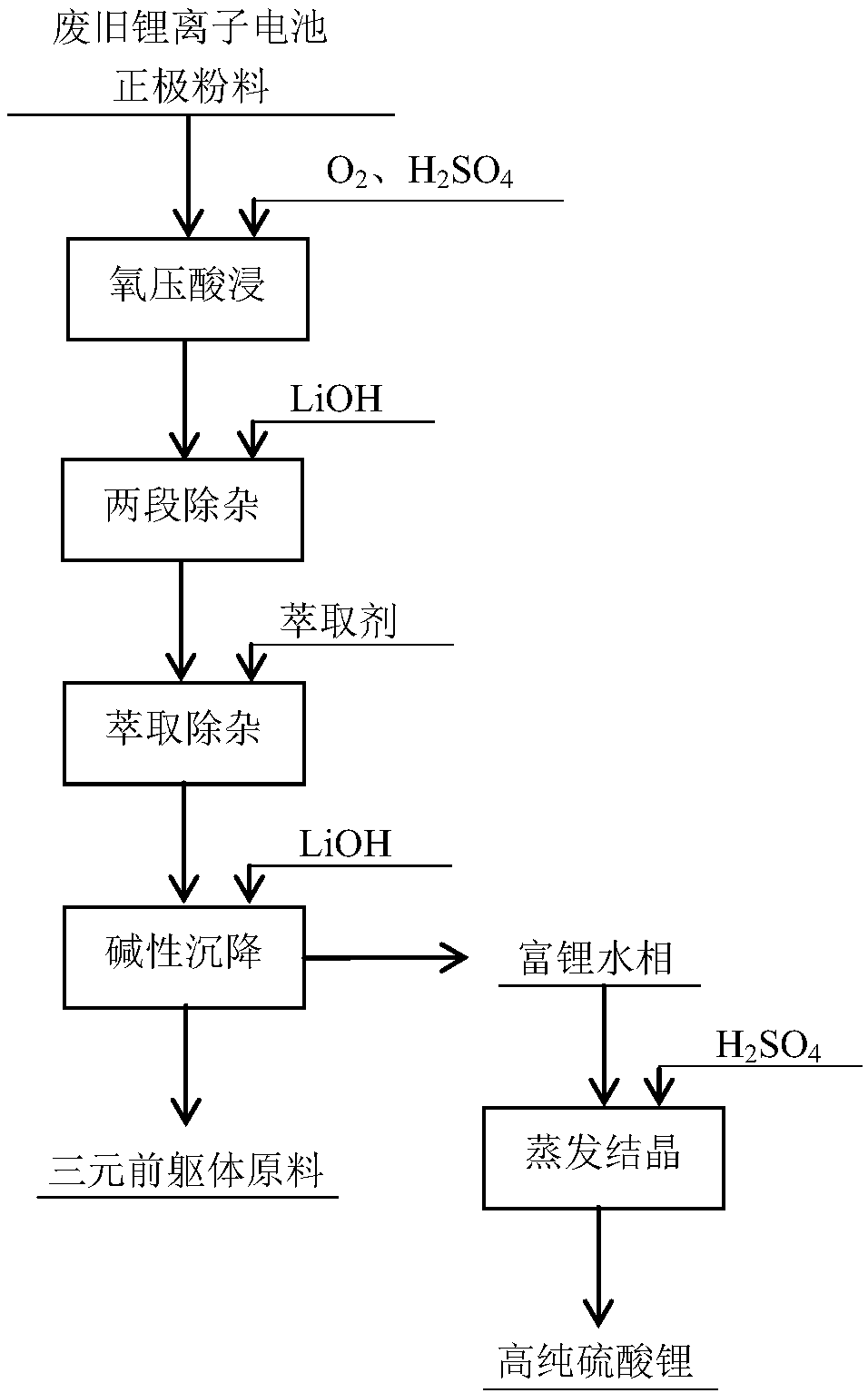

[0027] A method for recycling the positive electrode powder of waste lithium-ion batteries, comprising the following steps:

[0028] S1. Oxygen pressure acid leaching: add water to the positive electrode powder of waste lithium-ion batteries, add acid, pre-fill with oxygen, react at a temperature of 120°C, and filter to obtain acid leaching materials;

[0029] S2. Two-stage impurity removal: adjust the acid leaching material of S1 to pH 2.5 with an acidity regulator, react at a temperature of 80°C for 1 hour, filter, use an acidity regulator to adjust the pH value of the filtrate to 6, and react at a temperature of 70°C for 2 hours , filtered to obtain the impurity removal liquid;

[0030] S3. Extraction and impurity removal: adjust the pH value of the S2 impurity removal solution to 5, the saponification rate is 70%, O / A=1:2, four-stage countercurrent, and obtain a pure lithium-nickel-cobalt-manganese aqueous phase;

[0031] S4. Alkaline precipitation: Lithium nickel cobalt ...

Embodiment 2

[0035] A method for recycling the positive electrode powder of waste lithium-ion batteries, comprising the following steps:

[0036] S1. Oxygen pressure acid leaching: add water to the positive electrode powder of waste lithium-ion batteries, add acid, pre-fill with oxygen, react at a temperature of 150°C, and filter to obtain acid leaching materials;

[0037] S2. Two-stage impurity removal: adjust the acid leaching material of S1 to pH 1.5 with an acidity regulator, react at a temperature of 95°C for 1 hour, filter, use an acidity regulator to adjust the pH of the filtrate to 4, and react at a temperature of 90°C for 1 hour , filtered to obtain the impurity removal liquid;

[0038] S3. Extraction and impurity removal: adjust the pH value of S2 impurity removal solution to 2, saponification rate 20%, O / A=1:4, six-stage countercurrent, to obtain pure lithium nickel cobalt manganese aqueous phase;

[0039] S4. Alkaline precipitation: Lithium nickel cobalt manganese water phase ...

Embodiment 3

[0043] refer to figure 1 , the present invention proposes the recycling method of waste lithium-ion battery cathode powder, comprising the following steps:

[0044] S1. Oxygen pressure acid leaching: Add water to the positive electrode powder of waste lithium-ion batteries at a solid-to-liquid ratio of 1:3, add sulfuric acid according to 0.85 times the theoretical amount of the total metal content contained in the positive electrode powder and sulfuric acid reaction, and pre-fill with oxygen to The pressure of the system is 0.42MPa, the temperature is 142°C under stirring for 3 hours, the stirring speed is 550r / min, and the acid leaching material is obtained by filtration;

[0045] S2, two-stage impurity removal: adjust the acid leaching material of S1 to pH 2.2 with an acidity regulator, react at a temperature of 90°C for 1.5h, filter while hot, use an acidity regulator to adjust the pH value of the filtrate to 5, and ℃ for 2 hours, filtered to obtain the impurity removal so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com