Preparation method and application of zeolite molecular sieve crystal surface assembled metal organic framework membrane

A metal organic framework, zeolite molecular sieve technology, applied in organic chemistry, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of less research, limited selectivity control, etc. The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

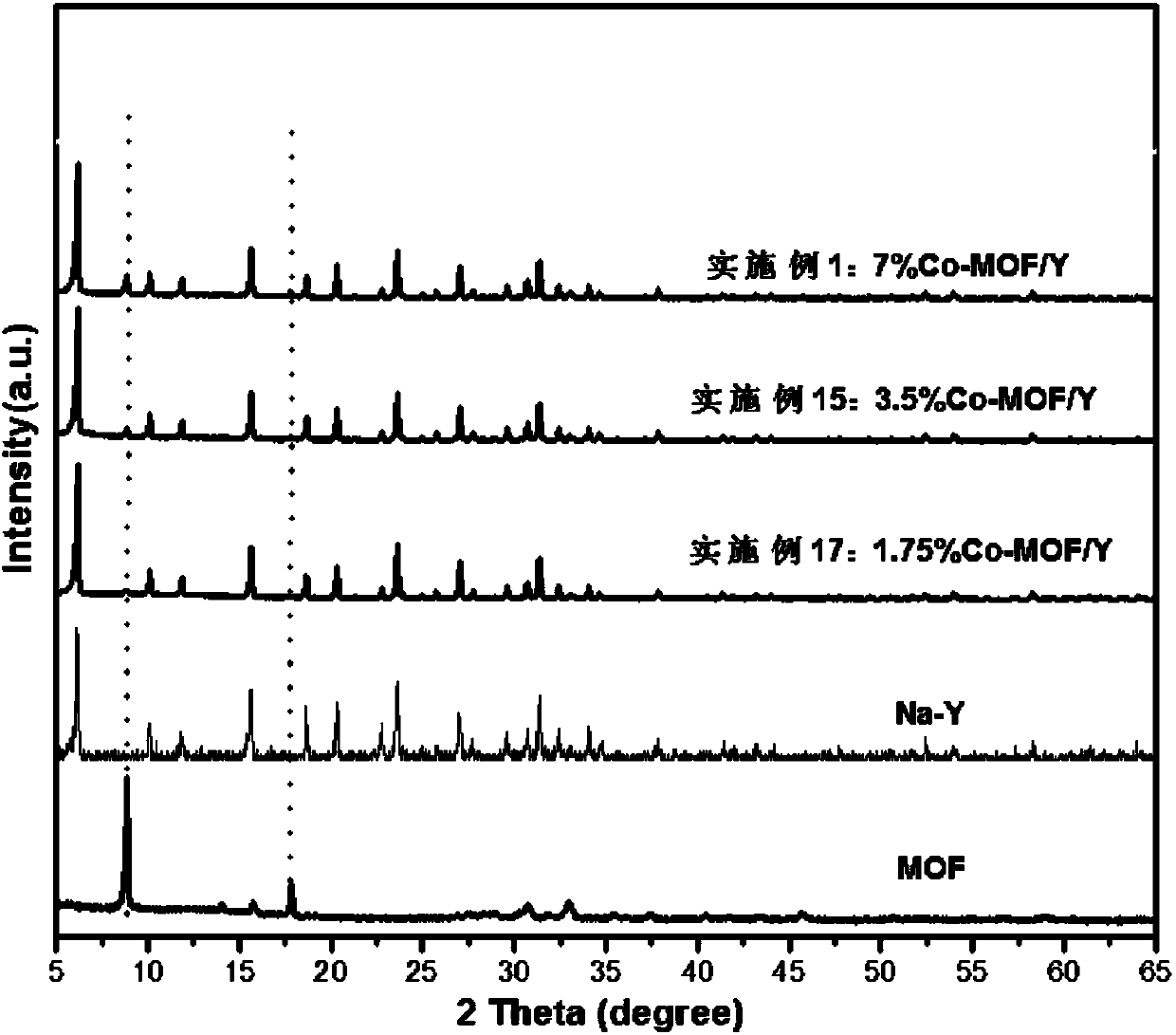

Embodiment 1

[0035] (1) A synthetic method for assembling a metal-organic framework membrane material on the surface of zeolite molecular sieve crystal grains, comprising the following steps:

[0036] 1) Precursor preparation:

[0037] First, add 0.747g cobalt acetate, 0.5g terephthalic acid, and 2.5g Y into the beaker, and add 60g N,N-dimethylformamide (DMF) (metal cobalt salt: terephthalic acid: DMF according to the molar amount of substance The ratio is 1:1:111.2, the mass ratio of metal cobalt salt and molecular sieve is 0.299:1), and the self-assembly reaction is carried out by stirring in a water bath on a magnetic stirrer at 40°C for 4 hours, followed by suction filtration, washing with hot DMF and hot ethanol, and vacuum drying Obtain the metal organic framework membrane material precursor assembled on the surface of the zeolite molecular sieve grain;

[0038] 2) Steam-assisted crystallization reaction:

[0039] Put the precursor material obtained in 1) into a 20ml polytetrafluor...

Embodiment 2~20

[0046] In Examples 2-20, according to the technical solution provided by the present invention, the ratio of raw materials is adjusted within the given range, and the performance of the obtained products is equivalent. The implementation process is the same as in Example 1 except for the following differences. For the relevant results, see Table 1 for the formulations of Examples 1 to 20 and Table 2 for the formulation and test results of catalytic α-pinene and air epoxidation.

[0047] Table 1

[0048]

[0049]

[0050] Table 2

[0051]

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com