Dual-scale pore structure nanocrystalline cobalt titanate powder and preparation method thereof

A pore structure, cobalt titanate technology, applied in the field of porous materials, can solve the problems of complex preparation process, unfavorable industrialization, single pore structure, etc., and achieve the effects of simple operation, low cost and low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Adopt 1.94g cobalt nitrate hexahydrate, cobalt nitrate and water are mixed according to the ratio of molar ratio 1:20, obtain cobalt nitrate aqueous solution;

[0029] Stir and mix absolute ethanol, tetrabutyl titanate and complexing agent diethanolamine evenly to prepare solution A, the molar ratio of tetrabutyl titanate to complexing agent is 1:0.7; absolute ethanol and tetrabutyl titanate The mass ratio of ester is 18:1;

[0030] Under stirring conditions, drop glacial acetic acid into solution A until the pH value is 4.5 to prepare solution B;

[0031] Under the condition of a stirring speed of 500rpm, drop the cobalt nitrate aqueous solution into the B solution, the dropping speed is 1mL / min, the amount of the cobalt nitrate aqueous solution is 1:1 according to the molar ratio of cobalt nitrate and tetrabutyl titanate Continue stirring until the formation of cobalt titanate sol (according to Tyndall phenomenon);

[0032] Place the container containing the cobalt ...

Embodiment 2

[0036] Method is with embodiment 1, and difference is:

[0037] (1) The mol ratio of cobalt nitrate and water is 1:12;

[0038] (2) The molar ratio of tetrabutyl titanate and complexing agent in A solution is 1:1.5; The mass ratio of absolute ethanol and tetrabutyl titanate is 21:1;

[0039] (3) Glacial acetic acid is dripped into solution A until the pH value is 3.5;

[0040] (4) Under the condition of a stirring speed of 600rpm, the cobalt nitrate aqueous solution was dropped into the B solution, and the dropping speed was 1.5mL / min;

[0041] (5) The temperature of the water bath is 45°C;

[0042] (6) Drying temperature 105°C, time 2h; roasting temperature 650°C, time 2h;

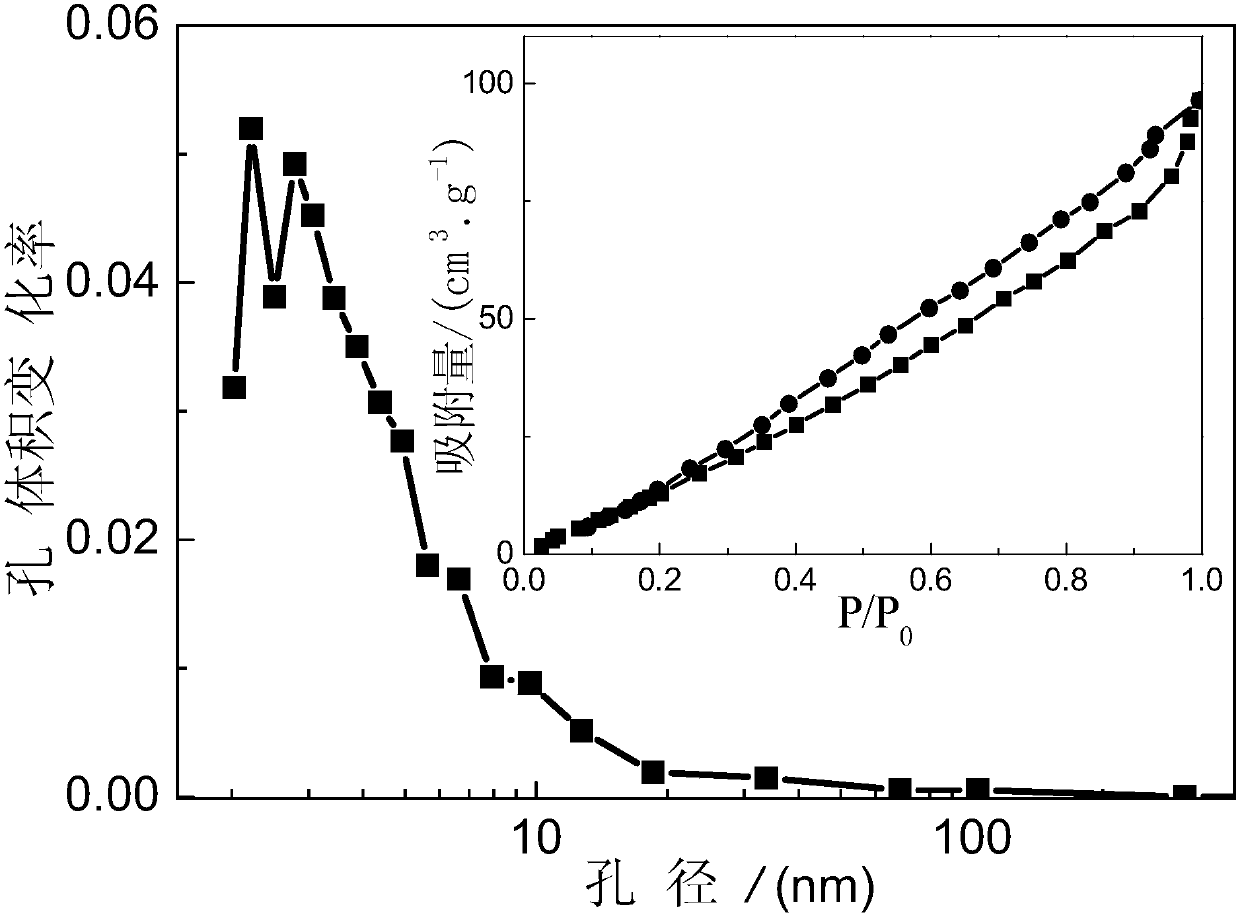

[0043] The specific surface area of nanocrystalline cobalt titanate powder with double-scale pore structure is 102.5m 2 / g, cobalt titanate weight content 98.9%;

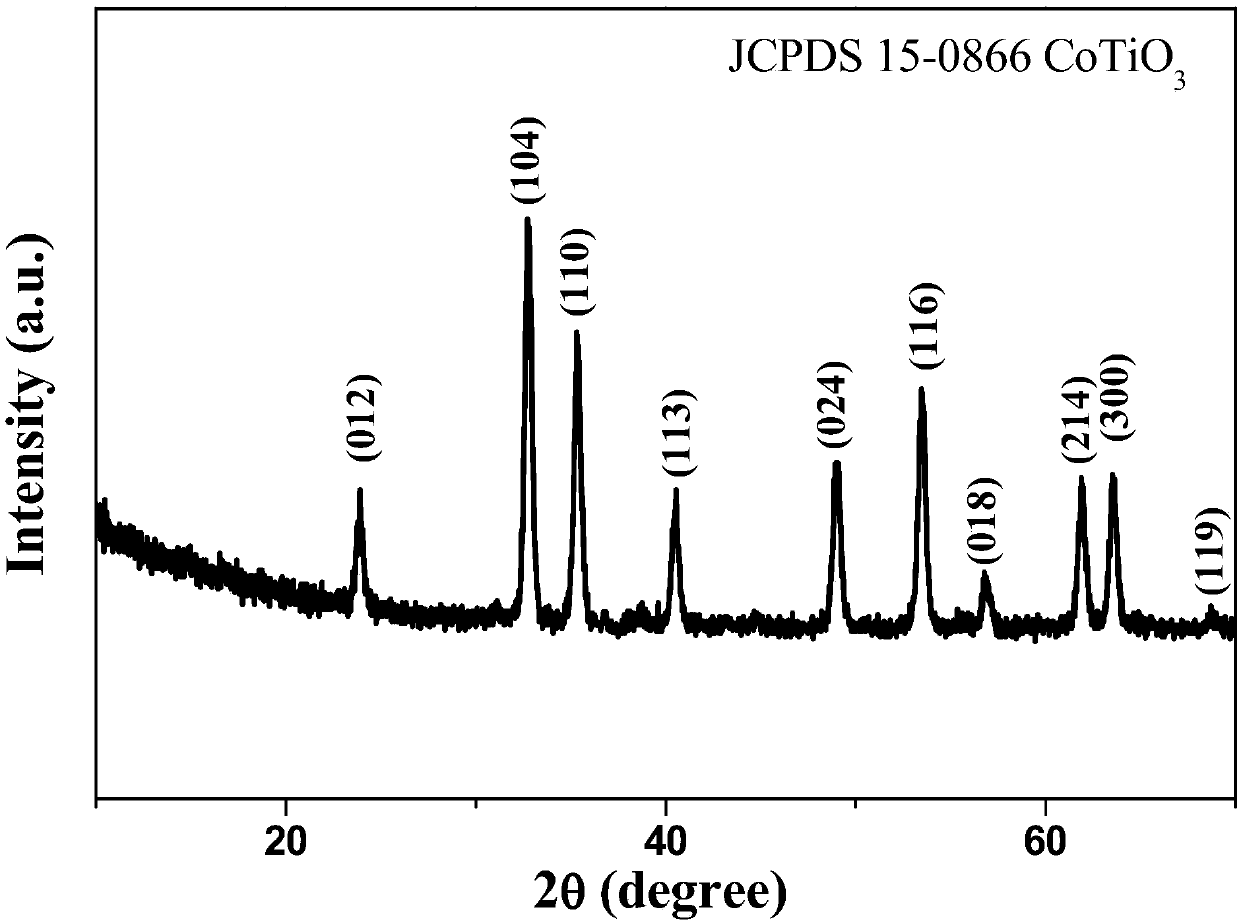

[0044] Phase composition XRD analysis such as figure 1 It can be seen from the figure that the cobalt titanate obtained by calcination...

Embodiment 3

[0048] Method is with embodiment 1, and difference is:

[0049] (1) The mol ratio of cobalt nitrate and water is 1:50;

[0050] (2) The molar ratio of tetrabutyl titanate and complexing agent in solution A is 1:2; the mass ratio of absolute ethanol and tetrabutyl titanate is 15:1;

[0051] (3) Glacial acetic acid is dripped into solution A until the pH value is 2.5;

[0052] (4) Under the condition of a stirring speed of 700rpm, the cobalt nitrate aqueous solution was dropped into the B solution, and the dropping speed was 2mL / min;

[0053] (5) The temperature of the water bath is 50°C;

[0054] (6) Drying temperature 95°C, time 4h; roasting temperature 600°C, time 3.5h;

[0055] The specific surface area of nanocrystalline cobalt titanate powder with double-scale pore structure is 95.3m 2 / g, the weight content of cobalt titanate is 98.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com