A silicon alkoxide-terminated silicone polyamine curing agent and self-healing epoxy resin prepared therefrom

A technology of epoxy resin and curing agent, which is applied in the field of epoxy resin, can solve the problems of limited use range, etc., and achieve the effect of low cost, wide source of raw materials, and simple repair method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

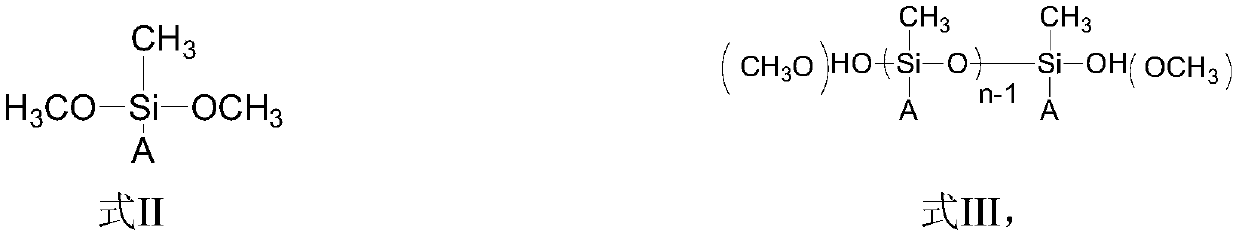

[0051] Embodiment 1, the synthesis of aminopolysiloxane

[0052] Add 540g of 3-aminopropylmethyldimethoxysilane and 144g of deionized water into a 1L three-necked flask equipped with a mechanical stirrer, a thermometer and a reflux condenser, and heat to 60°C for hydrolysis and condensation reaction. The reaction lasts for 12 hours. After the reaction was completed, vacuum distillation was carried out to remove methanol and water generated during the condensation process to obtain 375 g of a colorless and transparent aminopropylmethylpolysiloxane product with a number average molecular weight of 1200 and named as PAMS-1.

Embodiment 2

[0053] Embodiment 2, the synthesis of aminopolysiloxane

[0054] Add 620g of N-aminoethyl-3-aminopropylmethyldimethoxysilane and 144g of deionized water into a 2L three-necked flask equipped with mechanical stirring, a thermometer and a reflux condenser, and heat to 80°C for hydrolysis and condensation reaction , The reaction lasted 9h. After the reaction, carry out vacuum distillation to remove methanol and water produced in the condensation process to obtain 442g colorless and transparent N-aminoethyl-3-aminopropylmethylpolysiloxane product with a number-average molecular weight of 1458, named as PAMS-2.

Embodiment 3

[0055] Embodiment 3, the synthesis of aminopolysiloxane

[0056] Add 900g of diethylenetriaminopropylmethyldimethoxysilane and 144g of deionized water into a 2L three-necked flask equipped with a mechanical stirrer, a thermometer and a reflux condenser, heat to 90°C for hydrolysis and condensation reaction, and the reaction lasts for 4 hours . After the reaction was completed, vacuum distillation was carried out to remove methanol and water generated during the condensation process to obtain 746 g of a colorless and transparent diethylenetriaminopropylmethylpolysiloxane product with a number average molecular weight of 2251 and named as PAMS-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com