A kind of preparation method of ketone-rich bio-oil and magnesium-rich activated carbon

A bio-oil and activated carbon technology, applied in the field of agricultural and forestry waste pyrolysis, can solve the problems of low utilization efficiency of biomass energy, consumption of large chemicals, and no efficient utilization, etc., to reduce the content of oxygen-containing substances, reduce complexity, and improve The effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A method for preparing ketone-rich bio-oil and a method for preparing magnesium-rich activated carbon provided in the embodiments of the present invention, wherein the ketone-rich bio-oil is obtained by pyrolysis of seawater modified agricultural and forestry waste, such as Figure 4 As shown, it includes the following steps:

[0034] 1) washing agricultural and forestry waste with deionized water, grinding and sieving to obtain agricultural and forestry waste powder;

[0035] 2) Mix the agricultural and forestry waste powder obtained in step 1) with seawater, and use magnetic stirring to fully mix the two to obtain a mixture, and then dry the mixture to obtain the agricultural and forestry waste powder modified by seawater, wherein The main component in seawater is MgCl 2 , the concentration is 1540mg / L, that is, one liter of seawater contains 1540mg of MgCl 2 ;

[0036] 3) Send the modified agricultural and forestry waste powder obtained in step 2) into a pyrolysis...

Embodiment 1

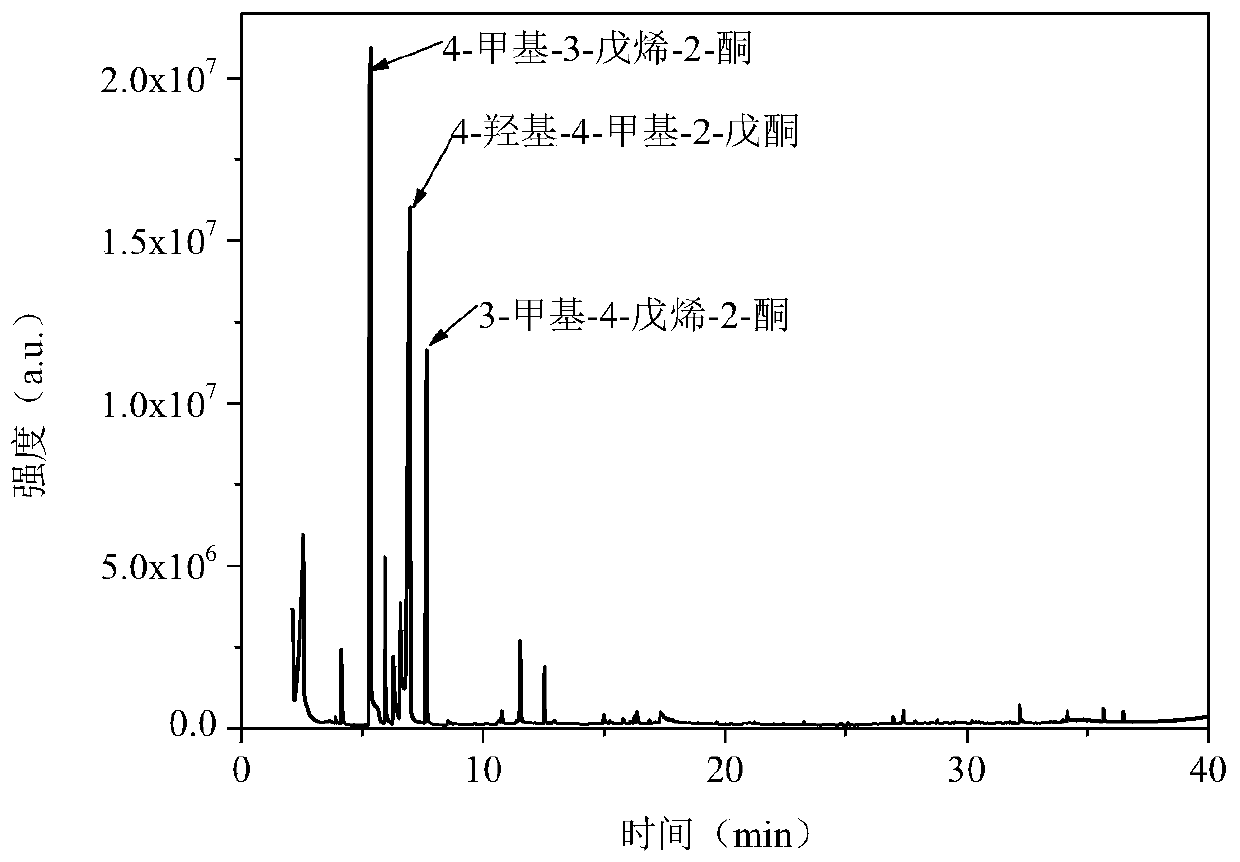

[0049] Crush and sieve corn stalks to 60-120 mesh, put them in an oven and dry at 105°C for 24 hours to obtain corn stalk powder, mix corn stalk powder and seawater with different solid-to-liquid ratios (3, 1.5, 1, 0.75, 0.6 ) for mixing, and using magnetic stirring for 4 hours to fully mix the corn stalk powder and seawater to obtain a uniformly mixed mixture of corn stalk powder and seawater, and dry the mixture of corn stalk powder and seawater at 105 ° C for 24 hours to obtain modified corn Rod powder; use a fixed-bed reactor (ie, a pyrolysis furnace) with a diameter of 45mm and a length of 60mm for pyrolysis, and heat the reactor to a specified temperature of 550°C at a heating rate of 10-20°C / min. Biomass (modified corn stalk powder) is quickly sent into the middle of the reactor, and the reaction time is 30 minutes, so that the modified biomass is fully pyrolyzed, and the pyrolysis reaction obtains pyrolytic charcoal and produces volatile matter, which is pyrolyzed in a ...

Embodiment 2

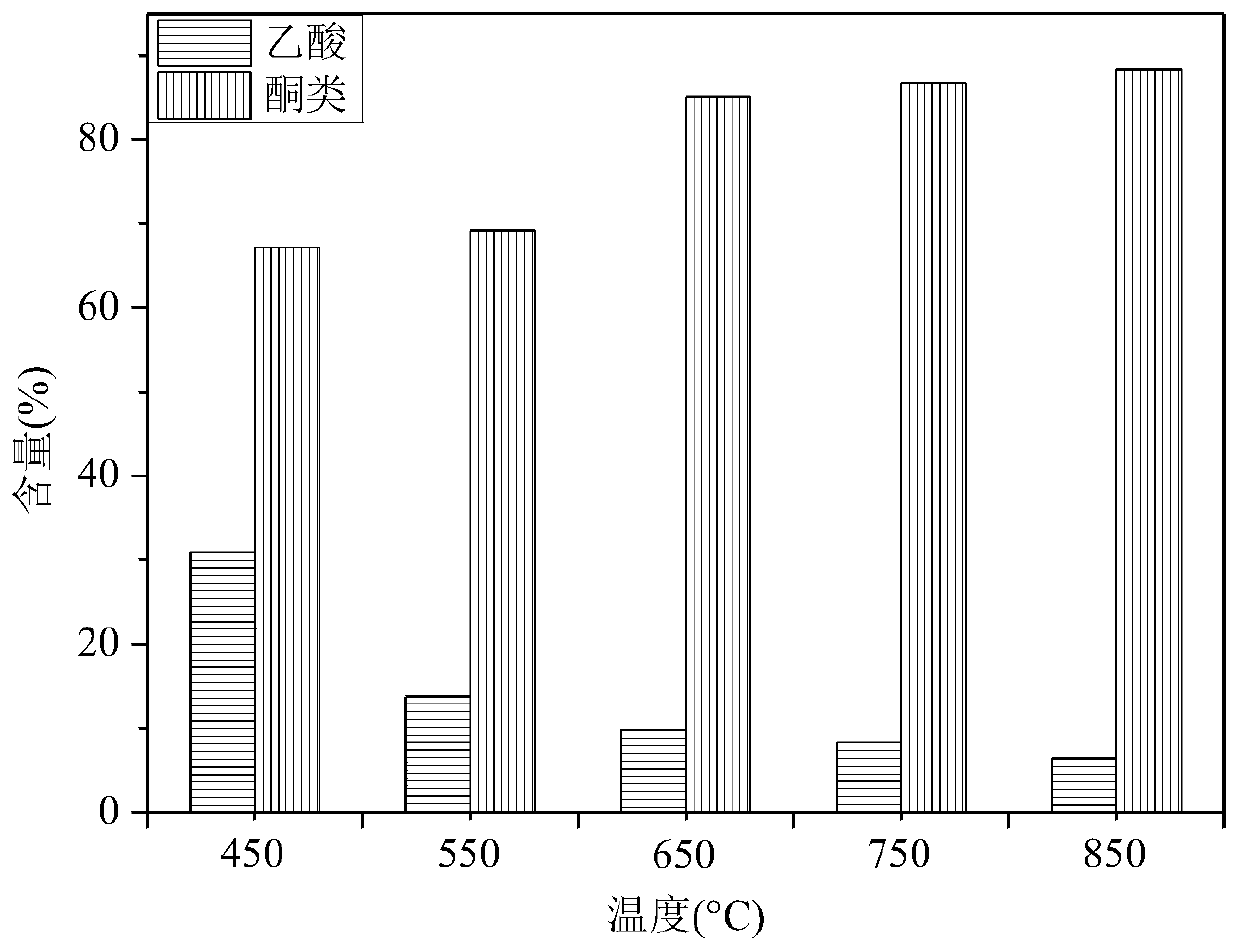

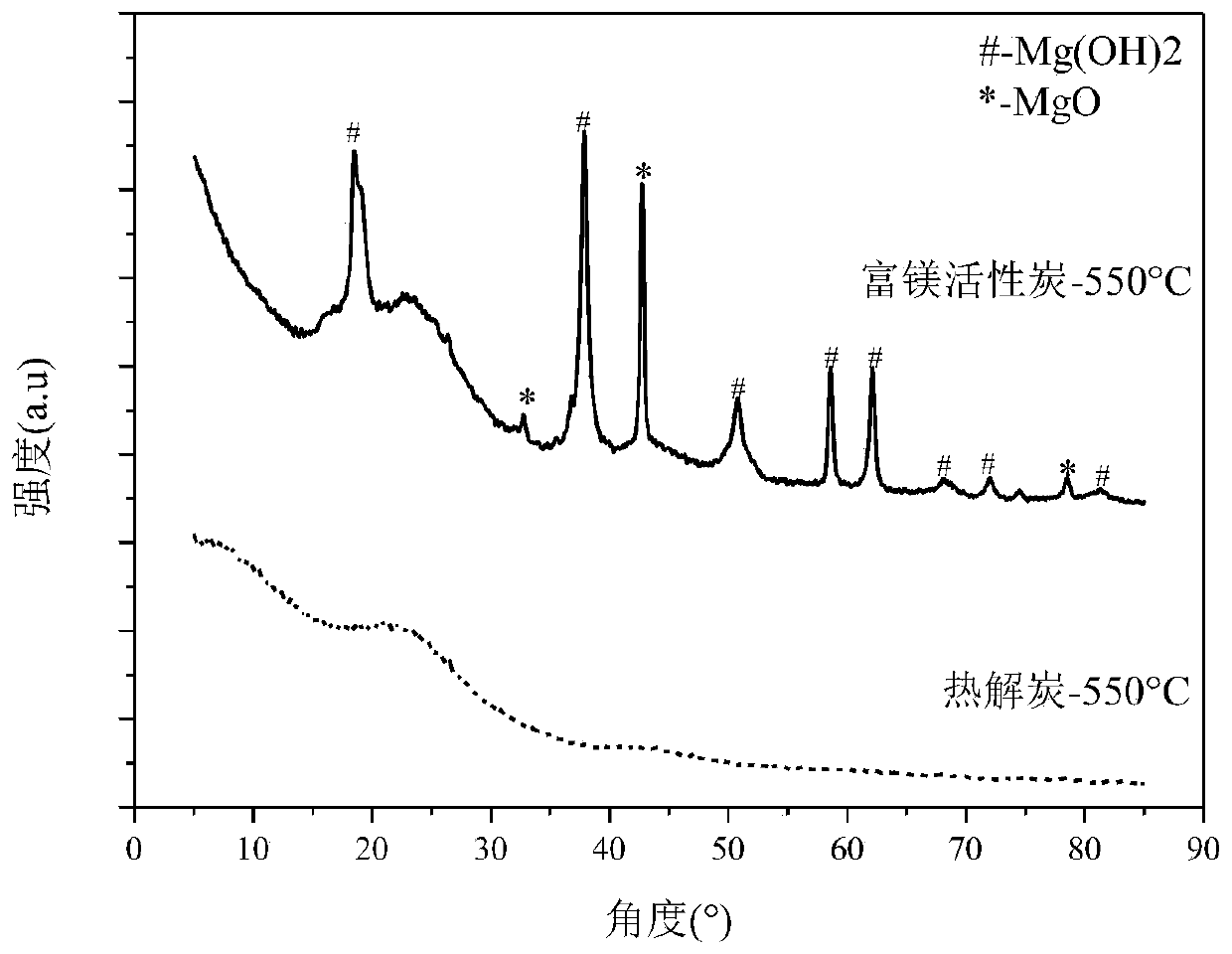

[0052] Control the solid-liquid mixing ratio of cornstalk and seawater to 2:5, and study the effect of pyrolysis temperature on ketone-rich bio-oil and magnesium-rich activated carbon. The pyrolysis temperatures are 450°C, 550°C, 650°C, 750°C, and 850°C, respectively , other conditions are identical with embodiment 1. Such as figure 2 As shown, at the pyrolysis temperatures of 450°C, 550°C, 650°C, 750°C and 850°C, the obtained bio-oils all contain high content of ketones, while the content of acetic acid is low, and the higher the temperature, the higher the ketones The higher the substance content, the lower the acetic acid content, and when the temperature reaches 850°C, the content of ketone substances tends to be stable. The magnesium-rich activated carbon prepared by the present invention has a high specific surface area, and has a higher magnesium content, such as image 3 As shown, the main forms of magnesium in activated carbon are MgO and Mg(OH) 2 , the magnesium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com