Method for preparing silicon nitride ferrovanadium

A technology of silicon vanadium nitride and silicon vanadium nitride, which is applied in the field of ferroalloys, can solve the problems of insufficient stability and precision, and achieve the effects of short alloying time, improved composition uniformity, and improved economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

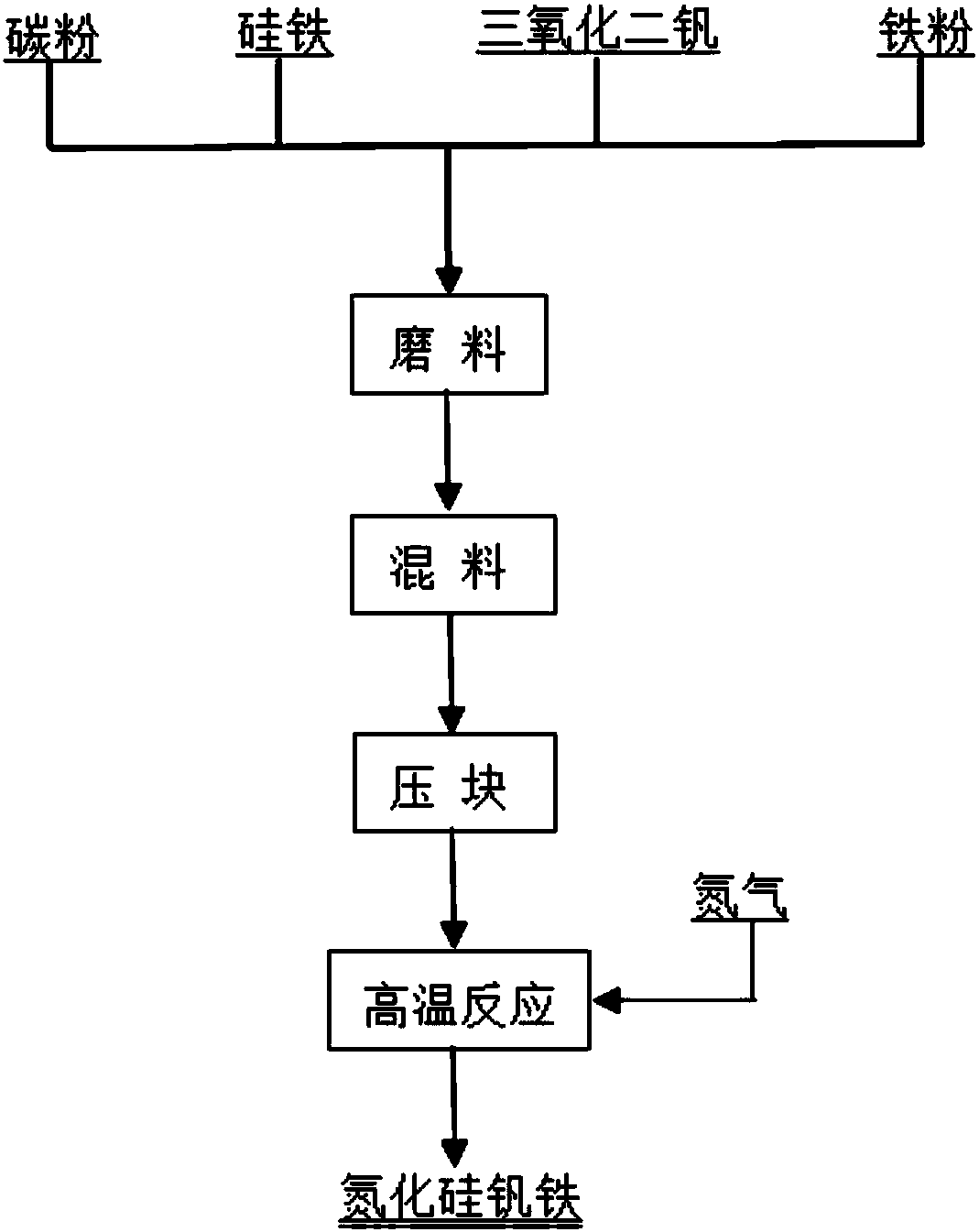

Method used

Image

Examples

Embodiment 1

[0036] (1) Weigh 403g of vanadium trioxide, 105g of carbon powder, 215g of ferrosilicon, and 410g of iron powder, and grind them respectively until the particle size is between 100-200 μm; put the above materials into a mixer and mix them for 30 minutes, and mix them evenly Four parts of materials are weighed from the powder, each part is 40g, and the small parts of materials are put into a cake press machine to be pressed into blocks, and the pressure is 35MPa;

[0037] (2) Put the lumpy material into the pusher kiln, with 300m 3 Nitrogen was introduced at a rate of / h, heated to 850°C for carbonization reaction, and after 6 hours of reaction, the temperature was raised to 1200°C for nitriding reaction. After 19 hours of heat preservation, the reaction was completed to obtain ferrosilicon vanadium nitride.

[0038] After detection, the V content in the obtained ferrosilicon nitride is 30%, the N content is 15%, and the Si content is 10%.

Embodiment 2

[0040](1) Weigh 403g of vanadium trioxide, 115g of carbon powder, 215g of ferrosilicon, and 410g of iron powder, and grind them respectively until the particle size is between 100-200 μm; put the above materials into a mixer and mix them for 30 minutes, and then mix them Four parts of materials are weighed from the powder, each part is 40g, and the small parts of materials are put into a cake press machine to be pressed into blocks, and the pressure is 30MPa;

[0041] (2) Put the lumpy material into the pusher kiln, with 280m 3 Nitrogen was introduced at a rate of / h, heated to 900°C for carbonization reaction, and after 7 hours of reaction, the temperature was raised to 1250°C for nitriding reaction. After 20 hours of heat preservation, the reaction was completed to obtain ferrosilicon vanadium nitride.

[0042] After testing, the V content in the obtained ferrosilicon nitride is 40%, the N content is 17%, and the Si content is 13%.

Embodiment 3

[0044] (1) Weigh 403g of vanadium trioxide, 134g of carbon powder, 215g of ferrosilicon, and 410g of iron powder, and grind them respectively until the particle size is between 100-200 μm; put the above materials into a mixer for mixing for 30 minutes, and mix them Four parts of materials are weighed from the powder, each part is 40g, and a small part of the materials is put into a cake press machine to be pressed into blocks, and the pressure is 28MPa;

[0045] (2) Put the lumpy material into the pusher kiln, with 250m 3 Nitrogen gas was introduced at a rate of 1 / h, and heated to 800°C for carbonization reaction. After 5 hours of reaction, the temperature was raised to 1300°C for nitriding reaction. After 20 hours of heat preservation, the reaction was completed to obtain ferrosilicon vanadium nitride.

[0046] After detection, the V content in the obtained ferrosilicon nitride is 38%, the N content is 14%, and the Si content is 12%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com