Flexible temperature sensor based on pectin/xanthan gum blend film and preparation method thereof

A temperature sensor and xanthan gum technology, applied in the field of sensors, can solve the problems of non-biodegradable flexible sensors, unsuitable for human body temperature detection, cumbersome preparation process, etc., and achieve real-time monitoring of human body temperature changes, simple structure, and high transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the flexible temperature sensor based on the pectin / xanthan gum blend film of the present invention comprises the following steps:

[0027] Step 1, preparing pectin sol.

[0028] Specifically, the pectin powder was dissolved in deionized water at 80° C. and stirred at a speed of 800 rpm until a uniform pectin sol with a concentration of 2% w / v was obtained.

[0029] Step 2, preparing a blend system solution.

[0030] In one embodiment, xanthan gum at a concentration of 0.3% w / v and 0.6 mL of glycerol are added to the pectin sol, and stirred at a speed of 1000 rpm to form a uniform blend system solution.

[0031] Step 3, preparing the mixed system sol.

[0032] In one embodiment, a 32 mM calcium chloride solution is configured in deionized water at a temperature of 80° C., wherein R=[Ca 2+ ] / 2[COO - ]=1, R is the molar ratio, the calcium chloride solution is added dropwise in the blending system solution by titration, and is stirred at a spe...

Embodiment 1

[0051] Fabrication of pectin / xanthan gum blend film flexible temperature sensor and testing of its sensing characteristics

[0052] The difference between the present embodiment one and the comparative example one is that before adding sodium chloride solution in step 2, add 0.3% (w / v) xanthan gum and plasticizer glycerin 0.6mL, stirring speed is 1000rpm, the rest The steps are the same as in Comparative Example 1.

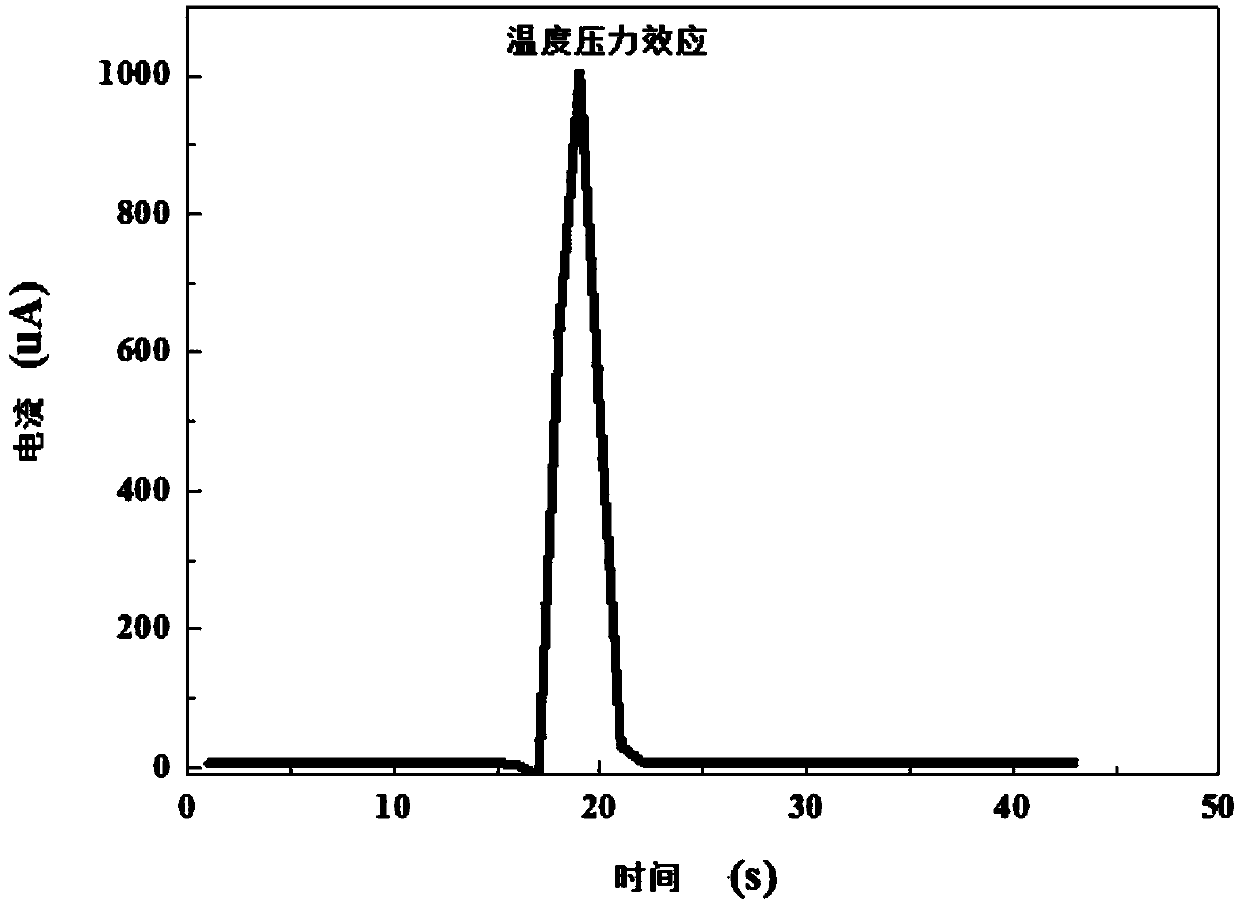

[0053] The responsiveness performance reference of this embodiment figure 2 , figure 2 It is the time response curve of the flexible temperature sensor based on the pectin / xanthan gum blend film in the present invention. Such as figure 2 As shown, it can be seen that its temperature response is high and its performance is good.

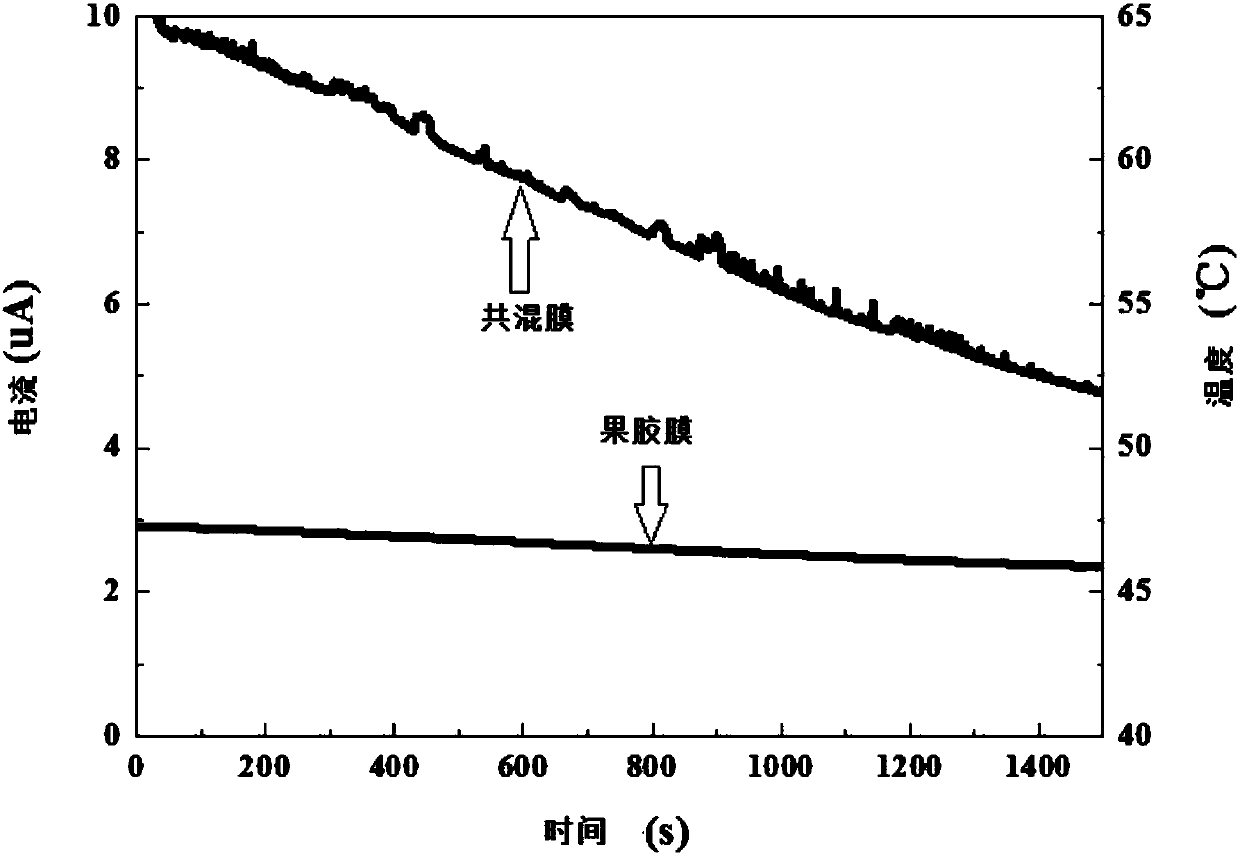

[0054] For the results of the performance tests of the above two examples, please continue to refer to image 3 , image 3 It is a sensitivity comparison chart of the flexible temperature sensor based on the pectin / xanthan gum bl...

Embodiment 2

[0056] Fabrication of pectin / xanthan gum blend film flexible temperature sensor and testing of its sensing characteristics

[0057] The difference between the second embodiment and the first embodiment is that the thickness of the flexible substrate layer prepared in step 1 is about 550 μm, the thickness of the flexible temperature-sensitive layer prepared in step 2 is 90 μm, and the rest of the steps are the same as in the first embodiment .

[0058] The response performance of this embodiment is similar to that of the first embodiment: the temperature response is very high and the performance is good.

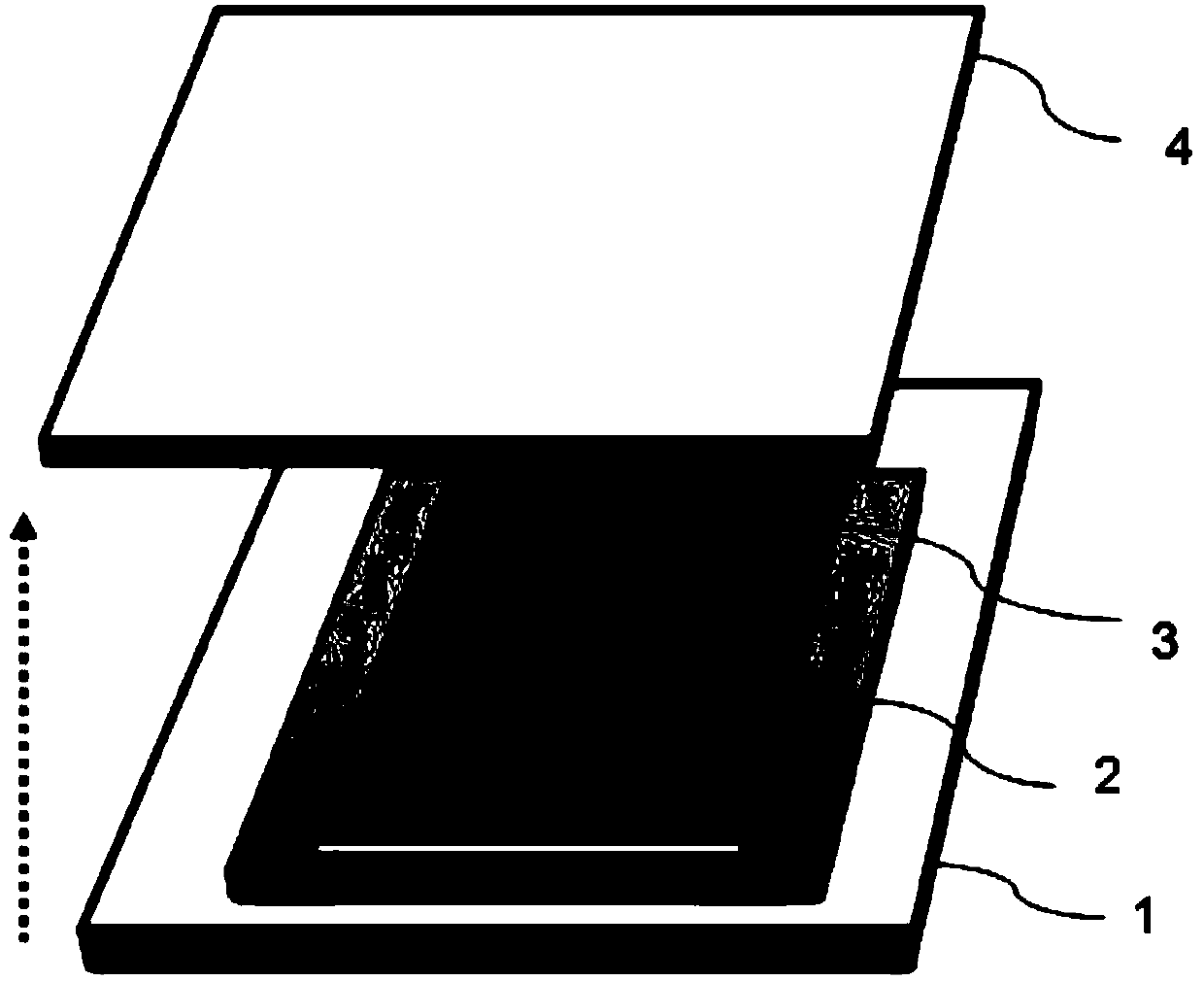

[0059] Those of ordinary skill in the art should be able to understand that one of the characteristics or purposes of the present invention is: the temperature sensor uses a pectin film as a temperature-sensitive material, and xanthan gum is added to improve the flexibility of the film and increase its responsiveness; PDMS is used as a flexible transparent substrate with upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com