Determination method for detecting 14 disabled colorants in cigarette paper by ultra-performance liquid chromatography-tandem mass spectrometry

A technology of ultra-high performance liquid chromatography and tandem mass spectrometry, which is applied in the field of determination of 14 banned colorants in cigarette paper by ultra-high performance liquid chromatography-tandem mass spectrometry, which can solve difficult separation, large matrix interference, and many kinds of colorants problems, to achieve the effect of reducing interference, less environmental pollution, and simple pre-treatment methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0033] 1. Instruments and reagents:

[0034] Colorants are prohibited, acetonitrile and ethanol are chromatographic grade reagents; they meet the requirements of first-grade water in GB / T 6682.

[0035] Waters TQS quadrupole tandem mass spectrometer; Swiss Mettler AE 163 electronic balance (sensitivity: 0.0001g).

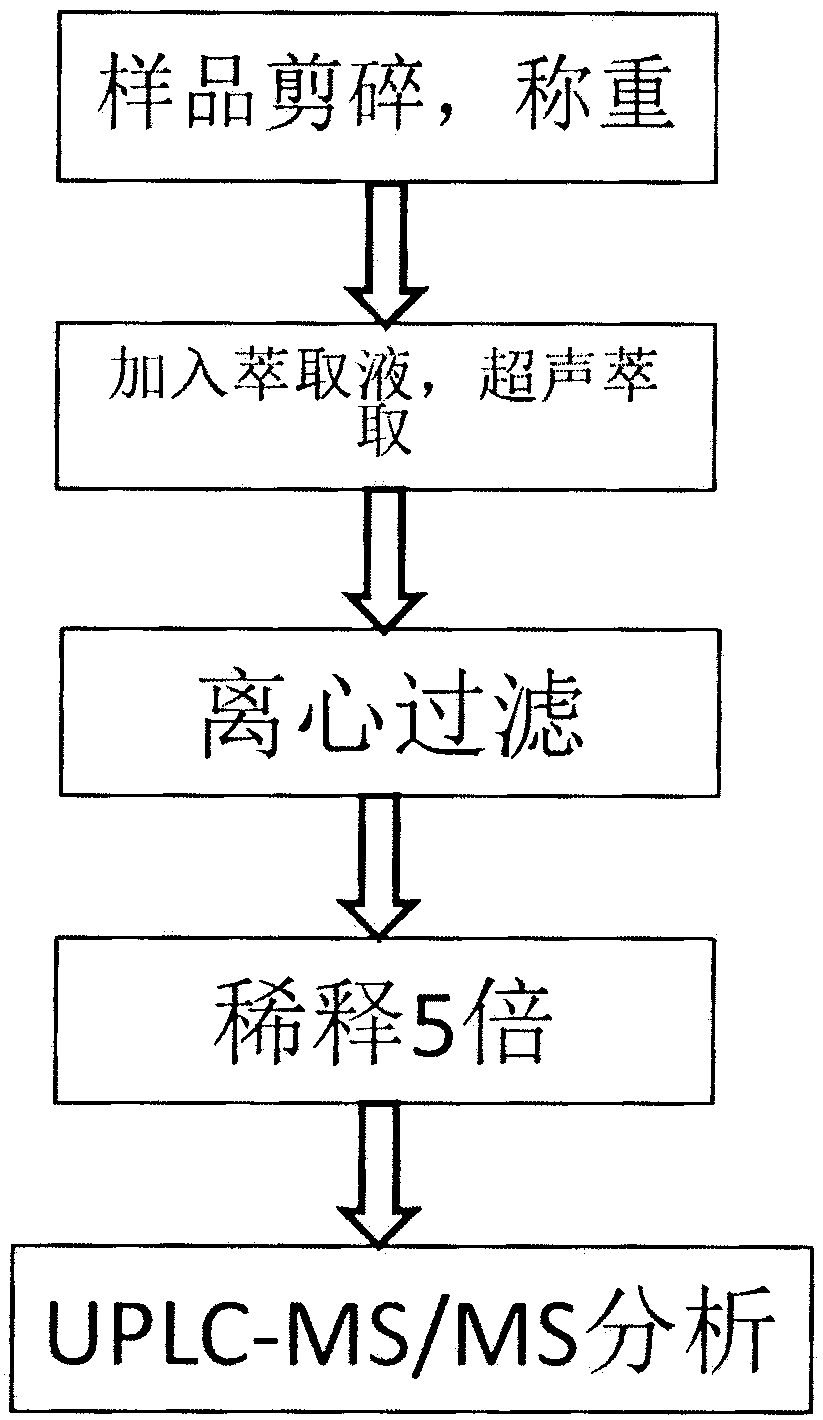

[0036] 2. Sample handling:

[0037] Weigh 0.5 g carton packing paper sample (accurate to 0.01 g), and place it in a 50 mL Erlenmeyer flask with a stopper. Accurately add 20mL extract: ethanol, ultrasonically extract for 30 min; sample purification: stand still for 5 min, pipette 1.5 mL of extract into a 2 mL centrifuge tube, and centrifuge at 8000 rpm for 5 min. Aspirate 1mL of the supernatant, blow it nearly dry with nitrogen, reconstitute with 1mL of acetonitrile, and filter through a 0.22μm organic phase filter. Pipette 200 μL of the filtrate, dilute the sample to 1.0 mL with acetonitrile, and use it as the sample solution for UPLC-MS / MS analysis;

[0038] ...

example 2

[0042] As the method described in Example 1, another tipping paper sample for cigarettes was selected, and no forbidden colorant was detected in the sample.

example 3

[0044] According to the method described in Example 1, another cigarette paper sample was selected, and the forbidden colorant was not detected in the sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com